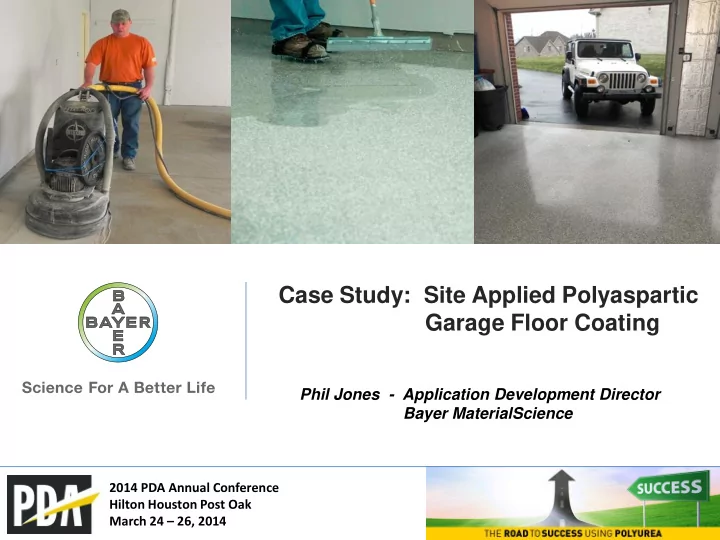

Case Study: Site Applied Polyaspartic Garage Floor Coating Phil Jones - Application Development Director Bayer MaterialScience 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Agenda Introduction to Market Area The Technology: Polyaspartic Review Site and Surface Preparation Coating Procedure and Application Performance Observations Applications for Other Adjacent Markets Questions and Answers 2014 PDA Annual Conference Hilton Houston Post Oak Page 2 March 24 – 26, 2014

Residential Garage Floor Market Market Drivers for Residential Garage Floors Protects concrete from contaminates • Road Salt : Can cause spalling and concrete degradation • Motor Oil/Antifreeze : Can stain surface and get tracked into home later Provides aesthetically pleasing space • Decorative finish brightens area and adds color • Protects against hot tire staining of concrete • Expands usable space in a home 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

The Technology – Polyaspartic Review Polyaspartic Coatings High film build and fast curing floor coatings with excellent clarity, gloss and longevity Sometimes called “Paint on Steroids” • Many decorative floor coatings are less than 4 mils thick Polyaspartic technology allows for higher film builds • “Watching Paint Dry” means more labor time Polyaspartic cures fast so allows a fast return-to-service Polyaspartics have 15+ year track record in industrial coatings 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

The Technology – Polyaspartic Review Polyaspartic Chemistry Coatings are 2K aliphatic polyurea products based on polyaspartic resins and aliphatic isocyanates OCN + NCO Polyaspartic Resins Aliphatic Isocyanate React to form A Polyaspartic Coating 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

The Technology – Polyaspartic Review Benefits: Excellent durability Fast return-to-service time High build per coat VOC compliance Extends application season Excellent ‘color pop’ on decorative stained floors Limitations: Difficult to downgloss Two component product so requires a mixing step Smaller batches must be mixed 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

The Technology – Polyaspartic Review Typical Performance Characteristics: Mix ratio of 2:1 to 1:1 by volume depending on formula Working time is typically 30-60 minutes at 75 F/ 50% RH Dry Time is 2 hours by Gardner Circular test at 75 F/ 50% RH Dry Film Thickness: 5 - 15 mils. Excellent color and gloss retention Hardness: 60 to 80 Shore D Taber Abrasion: 25 - 60mg (CS-17) Elongation at Break: 4 - 100% VOC: near zero to 100g/L 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Case Study – Site Review and Surface Preparation Surface Preparation is the key to a successful project Site logistics were considered first: Location of access points, switches, day joints, and drains were noted. Temperature and humidity noted. Existing slab was inspected: Contractor looked for cracks, spalling, porosity, soaked-in contaminants. Oil or coolant stains were cleaned. Relief joints were cleaned out and filled: Joints were ground in order to enhance adhesion then were filled with polyurea caulk Surface grinding starts: Contractor found the concrete to have a high hardness so extra weight was added to the machine. 2014 PDA Annual Conference Hilton Houston Post Oak Page March 24 – 26, 2014 8

Case Study – Surface Preparation Concrete Surface Grinding Process - Advantages Yields a consistent, sharp profile Doesn’t micro -fracture the surface like blasting Doesn’t leave residual contaminates like acid etching HTC 500 Planetary Grinder 1 st Pass: 1820 Grit Diamonds 2 nd Pass: 3040 Grit Diamonds Final Profile: ICRI CSP 2-3 2014 PDA Annual Conference Hilton Houston Post Oak Page March 24 – 26, 2014 9

Case Study – Surface Preparation Joint Filler and Repairs Polyurea joint filler allowed low temperature cure and fast trimming Eliminates areas for dirt accumulation giving a cleaner look Product had a balance of elongation, hardness, and compressive strength Two Component Electric Drive Caulking Gun Aliphatic Polyurea Joint Filler Trimmed at 15-20 minutes 2014 PDA Annual Conference Hilton Houston Post Oak Page March 24 – 26, 2014 10

Case Study – Coating System The Coating System Used Gray Polyaspartic Basecoat Seals and bonds to prepared concrete surface Broadcast of Decorative Paint Chips Adds depth to decorative element Clear Polyaspartic Topcoat Locks the look in under a light stable finish System was applied to one half of garage first, then the other half 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Case Study – Coating Application Basecoat Application: 3/32 ” notched squeegee, back rolled with 3/8 ” nap roller, 8-12 mils WFT Decorative Chips: Full broadcast into wet basecoat, 1/8” - 1/4” three -color-blend chips Topcoat Application: 3/32 ” notched squeegee, back rolled with 3/8” nap roller, 10 -12 mils WFT 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Case Study – Coating Application Additional Project Details Job Completed Late Fall 2010 800 ft² garage space, South facing site Air Temperature was 35ºF, concrete floor temperature was 45ºF One garage door open during application for ventilation Snow flurries present during the installation! After applying the basecoat and chips, the floor cured for 1.5 hours Chipped finish was dragged with heavy bar Excess chips were vacuumed up The clear topcoat was allowed to cure before re-entering the jobsite: After two hours the floor accepted foot traffic After six hours, vehicle was parked in garage 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Case Study – The Finished Job 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Case Study – 3½ Years Later Site observations 3½ years after installation 95%+ gloss retention at garage opening 100% color retention at garage opening No hot tire staining – Bay 1 contains sports car, performance tires No hot tire pick up – Bay 2 contains heavy off-road vehicle No chemical staining – Vehicle and lawn mower oil easily wiped off No road salt damage – Northeast location means salt in winter No cracking or blistering – Coating is intact over filled joints 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Case Study – 3½ Years Later Still Looks Great After 3½ Years !!! 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Case Study – Home Owner Comments Homeowner Observations: 3½ Years After Installation “It’s nice to be able to hose the salt and road ash down the drain” “ I’ve used the new space as the eating area for a communion and confirmation party – and I’m not embarrassed” “Seamless floor is a plus since there isn’t that joint that collects dirt and leaves; it’s easier to sweep up” “I feel like I put on an addition to the house” 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Applications in Adjacent Markets Similar Areas Have Similar Needs Parking Decks: Fast cure means shorter return-to-service time and less revenue loss Commercial Space: Hotels and restaurants like the decorative finishes and quick installation Stadiums & Venues: Preferred for gloss and color retention plus cleanability and durability 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Thank You Phil Jones Director of Application Development Infrastructure & Building Materials, NAFTA Bayer MaterialScience LLC Coatings, Adhesives and Specialties, NAFTA 100 Bayer Road Pittsburgh, PA 15205 Phone: +1 412-777-7657 Cell: +1 412-639-3943 E-mail : Phil.Jones @ bayer.com 2014 PDA Annual Conference Hilton Houston Post Oak March 24 – 26, 2014

Recommend

More recommend