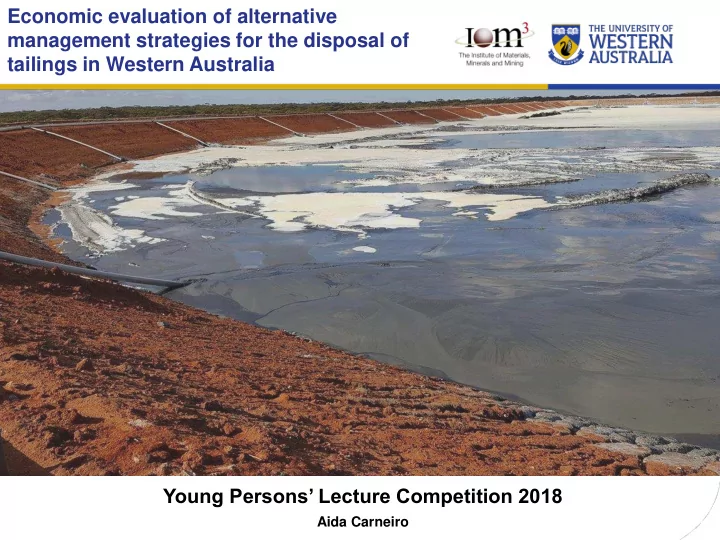

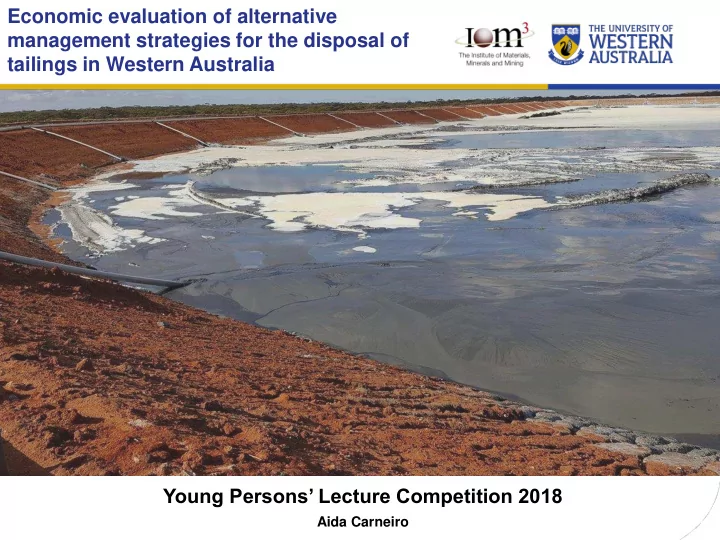

Economic evaluation of alternative management strategies for the disposal of tailings in Western Australia Young Persons’ Lecture Competition 2018 Aida Carneiro

What are Tailings? Tailings are the non-economic product of the mineral processing operation ( waste , chemicals , and process water) . Mine Production Cycle Increased realised benefits & increased costs? Concentrate Slurry Mineral Run-of-mine Processing (ROM) Plant Tailings Storage Thickened Tailings Facilities (TSFs) Filtered

Introduction • Sustainable development principles and leading practices • TSFs under increasing scrutiny • Current evaluation methodologies are limited • CAPEX and OPEX only, and just of certain items • Underestimation of closure costs, and overlook of non-technical issues ENVIRONMENTAL CAPEX SOCIAL OPEX RISK • Lack of economic data on tailings management

Review of increasing tailings management challenges • Need to balance economic, environmental and social issues • Water shortage and its increasing cost • Desalination cost in Chile US$5/m 3 • Social and environmental disputes • Onerous obstacles to obtain SLO Source: http://www.huffingtonpost.ca/2011/11/29/48-billion-peru-gold-mi_n_1119767.html http://www.yestolifenotomining.org/tia-maria-shouts-to-defend-their-land-peru/

Review of increasing tailings management challenges • Catastrophic environmental and public health impacts from TSF failures Mishor Rotem Israel, June 2017 Luoyang, Henan Province China, August 2016

Review of increasing tailings management challenges Samarco Lithgow Brazil, November 2015 Australia, July 2015 Mount Polley Canada, August 2014

Review of increasing tailings management challenges • TSF failures drive public perception • Increase regulatory burden and government oversight • Brazil’s bill PL 3676-2016: ban upstream method • Mining Rehabilitation Fund (MRF) – July 2013

Tailings physical characteristics, operating parameters, and design considerations • Non-acid generating gold tailings in WA • 75-80% < 75 μm • 266 mm rainfall, 2,500 mm evaporation • Flat topography • 2M dry tonnes per year • 15 years operating LOM • Conceptual TSF designs – Conventional slurry tailings (55% w/w) r d = 1.4 t/m 3 – Thickened tailings (65% w/w) r d = 1.5 t/m 3 – Filtered tailings (80% w/w – MC 25%) r d = 1.85 t/m 3

Typical Tailings Storage Facilities in WA Slurry tailings disposal in a paddock-type dam Decant road Thickened tailings disposal using CTD method 2 km Pond for surface water management Source: Google Maps

Typical Filtered Tailings Storage Facilities Filtered tailings disposal in a drystack-type facility in WA Decant road Source: Google Maps

TSF design for slurry tailings Water Return Water Return Pipeline Pump 200 mm Φ HDPE 2 x Centrifuge pumps 1,940 m long 25 m Φ x 3m 104 m 3 /h sidewall Thickener Spigot Dropper Tailings Deposition Pipeline 200 mm Φ HDPE 4,640 m long TSF Thickener 1,000 m away UF Pump 10 x Centrifuge pumps 272 m 3 /h Supply and Installation 55% Solids • High-rate thickener (HRT) 180 mm Φ HDPE 5,000 m long • Pumps and pipeline (tailings, return and make-up Make-up Water Pipeline water) • Pipe for spigot dropper • Spigot offtakes Make-up • Source of Make-up Water Earthworks (site preparation, embankment Water Pump 5,000 m away construction, underdrainage and decant systems) 2 x Centrifuge pumps 85 m 3 /h

TSF design for thickened tailings Water Return Pipeline Water Return 25 m Φ x 4.5m 225 mm Φ HDPE 1,038 m long sidewall Pump Thickener 125 m 3 /h – 6 months Tailings Deposition Pipeline 200 mm Φ HDPE 2,121 m long Thickener UF Pump Pond for Water 1 x Piston-diaphragm PD pump, 208 m 3 /h Management 65% Solids Supply and Installation TSF 1,000 m away 225 mm Φ HDPE • High-compression thickener 5,000 m long Make-up Water Pipeline • Pumps and pipeline (tailings, return and make-up water) • Spigot offtakes • Earthworks (site preparation, embankment Make-up Source of Make-up Water Water Pump construction, tailings deposition system, pond for 5,000 m away 125 m 3 /h – 6 months water management)

TSF design for filtered tailings Water Return Pipeline 160 mm Φ HDPE 1,000 m long Fast-opening 3 filters Water Return Filter Press 60 chambers each Pump 58 m 3 /h – 6 months Tailings Transport Tailings Placement by Truck by Dozer TSF Filter Cake Pond for Water 1,000 m away Management 289 t/h 80% Solids MC 25% Supply and Installation 160 mm Φ HDPE 5,000 m long Make-up Water Pipeline • Filtration plant (filters, pumps, compressors, cake conveyors, and slurry tank agitator) • Pumps and pipeline (return and make-up water) • Earthworks (site preparation, and pond for water Make-up Source of Make-up Water management) Water Pump 5,000 m away 58 m 3 /h – 6 months

Comparative evaluation summary Item Conventional Slurry Thickened Tailings Filtered Tailings Solids content of 55% (w/w) 65% (w/w) 80% (w/w) discharged tailings Dewatering unit High-compression Fast-opening filter High-rate thickener type thickener press Spigotting from a ring Central Thickened Tailings discharge dyke in a paddock Discharge (2% beach Drystack method dam angle) Deposited tailings 1.4 t/m 3 1.5 t/m 3 1.85 t/m 3 dry density TSF footprint area 94 ha 324 ha 48 ha 5 centrifugal + 5 1 piston-diaphragm Tailings transport Truck, dozer and standby pumps and PD pump + 2 charge system compactor pipeline pumps and pipeline Flow of water 189 m 3 /h 125 m 3 /h 58 m 3 /h discharged with tailings

Results and Discussion Net Present Cost @ 10% 160 Millions 1% 140 Estimated Cost (AUD) 120 AUD 3.26 / t 100 50% 80 CLOSURE OPEX 60 AUD 1.11 / t 78% AUD 0.98 / t CAPEX 40 20 0 56% Slurry Thickened Filtered Tailings Tailings Tailings

CAPEX comparison • Technology for high-density tailings = High CAPEX High-density Low-density Filtering thickening thickening technology technology technology 35 Estimated Cost (AUD) Millions • Filtered tailings = technology 30 25 50% 20 • Slurry and thickened tailings = 15 earthworks (site preparation, 10 water management, and 5 embankment construction) 0 Slurry Thickened Filtered Tailings Tailings Tailings • PD vs centrifugal pump 18% Dewatering Technology Thickener Underflow Pump Water Return Pump Make-up Water Pump Pipeline Earthworks

OPEX comparison • High cost of transporting, spreading and 1% compacting filter cake 28% • Increase TSF capacity, pump slurry and make- up water 70% • If water costs $3/m 3 = costs of make-up water Slurry 8% Filtered 47% 54% Thickened Distribution of operating costs for filtered tailings 78% 50 Millions 45 Estimated Cost 40 35 30 (AUD) Slurry Tailings 25 20 Thickened Tailings 15 Filtered Tailings 10 5 0 Increase TSF Tailings Filtration Tailings Water Return Make-up MRF Capacity Thickening Transport and Pumping Water Placement Pumping

OPEX comparison • MRF Regulation = $50,000/ha • Rehabilitation cost + project management + 20 years monitoring • $185,000/ha (slurry), $46,000/ha (thickened), $38,000/ha (filtered) • MRF = $100,000/ha and FCR = 1.5% MRF thickened tailings = 1/3 of total OPEX • Land under rehabilitation = $2,000/ha

Closure and rehabilitation cost comparison • Rehabilitation cost higher for CTD option Thickened tailings $ 2.5M 324 ha Slurry tailings $ 1.3M 94 ha Filtered tailings $ 0.5M 48 ha $12k / ha $76k / ha $15k / ha • Complex rehabilitation works for wet tailings 84% • Different life-cycle considered for discounting rehabilitation costs – LOM 34 years for slurry option – LOM 29 years for CTD and drystack options

Conclusion • Technology to improve water efficiency and lower the risks of catastrophic TSF failures • Key elements driving the cost of disposal – Transport and placement of filter cake (information on costs???) – Large footprint for tailings storage Land use – Volume of retaining embankment Risk of failure – Water loss Water scarcity – Rehabilitation work Tightening regulations

Ongoing Can the real costs of disposing tailings be research estimated? Estimate not only private but also environmental, social, and risk costs to internalise them in the decision making process Conventional Cost Direct and Indirect Accounting Financial Costs – Capital, Operational, Total Cost Life Cycle Assessment and Closure Costs Sustainability Full Cost Assessment Assessment “ Recognised ” Contingent Costs LCSA A Broader Range of Direct, Indirect, Contingent and Less Quantifiable Costs - Environmental Costs External Social Costs Borne by Society - Social Costs Source: after International Institute for Sustainable Development, 2013

Ongoing Can the real costs of disposing tailings be research estimated? • Due account of environmental, social and risk costs for the selection of the most cost-effective option • Disposal method should be selected based on the assessment of the accumulated costs using an integrated approach Thank you!

Recommend

More recommend