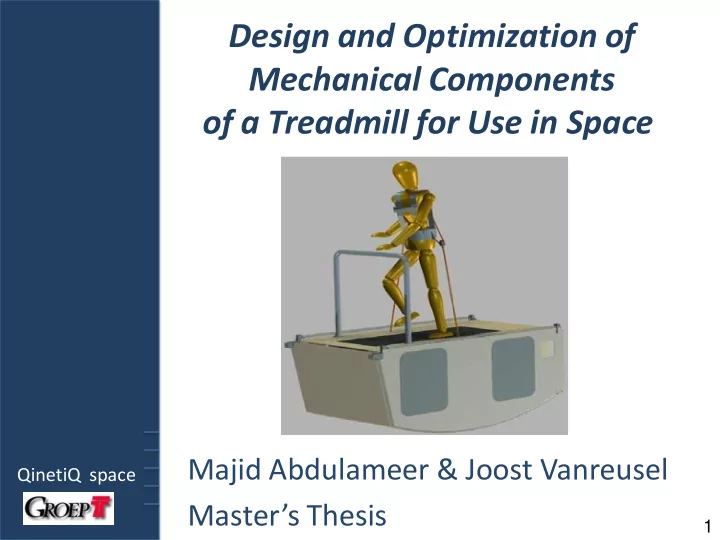

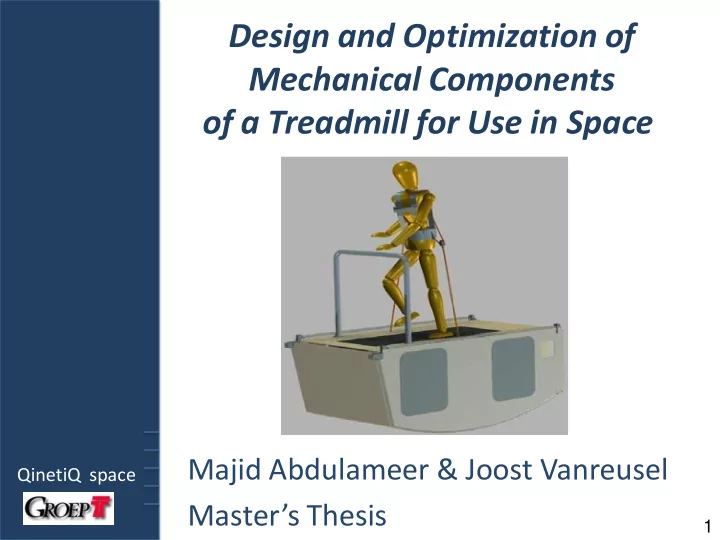

Design and Optimization of Mechanical Components of a Treadmill for Use in Space Majid Abdulameer & Joost Vanreusel QinetiQ space Master’s Thesis 1

Design and Optimization of Mechanical Components of a Treadmill for Use in Space Majid Abdulameer & Joost Vanreusel QinetiQ space Master’s Thesis 2

Design and Optimization of Mechanical Components of a Treadmill for Use in Space Majid Abdulameer & Joost Vanreusel QinetiQ space Master’s Thesis 2

PURPOSE: • Exercising in space is necessary to keep astronauts healthy and functional. On Earth, gravity works against our muscles and bones every time we move so our bodies maintain enough muscle and bone mass to be able to support our weight. In the weightless environment of space, where the relative force of gravity is minute, astronauts lose muscle and bone mass since it is not required to support their weight. The longer an astronaut is in microgravity, the greater the loss. Exercising in space is the most effective way to date to compensate for the relative lack of gravity. QinetiQ space 3

Although astronauts gradually recover their muscle tissue and bone when they return to Earth. It is important that they are strong enough to perform emergency procedures during landing. Completing a regular exercise routine in space prepares the astronaut for these situations and also facilitates a shorter period of rehabilitation to recover their muscle and bone. One of the important exercise equipment is treadmill . QinetiQ space 4

1. Overall principle of SLS system subject loading system QinetiQ space 5

1. Overall principle The system constantly provideds a pull down force of SLS system to the subject running on the treadmill in such way that the person is pulled towards the treadmill with a force of 1g the earth’s gravity. QinetiQ space 6

1. PARKING MECHANISM CONSTRAINTS • Mass • Dimensions • Reliability • Boundary conditions • Lifetime • Material requirements QinetiQ space 11

CONTENT 1. PARKING MECHANISM 2. EXIT PULLEY QinetiQ space 7

1. PARKING MECHANISM QinetiQ space 8

1. PARKING MECHANISM PURPOSE • Avoid slack of rope inside the mechanism in case of pressure loss of the activators. • Ensure that the rope remains on the pulleys internally to SLS at all times. • Parking mechanism starts working when there is less than 0.3 bar into the low pressure system. QinetiQ space 9

1. PARKING MECHANISM PURPOSE QinetiQ space 10

1. PARKING MECHANISM PROBLEMS & ALTERNATIVES • Spring • Rotation of cylinder • Cam system • Translating movement QinetiQ space 12

1. PARKING MECHANISM PROBLEM 1 Spring seizes compressed/uncompressed From Block level FMECA At item Block 1.11.3 Cause: Environmental conditions Effect: parking mechanism will not operate and rope may become dislocated from pulleys. Can we remove the spring from QinetiQ space the cylinder? 13

1. PARKING MECHANISM ALTERNATIVE 1 • 3/2-valve to make the parking cylinder bistable QinetiQ space 14

1. PARKING MECHANISM ALTERNATIVE 1 • Parked piston QinetiQ space 15

1. PARKING MECHANISM ALTERNATIVE 1 • Free piston QinetiQ space 16

1. PARKING MECHANISM PROBLEM 2 What do we mean by environmental conditions? (FMECA, QinetiQ, 2009, pp. 28-29) • It can be due to 2 DOF • Less movement means less vibration and longer lifetime QinetiQ space 17

1. PARKING MECHANISM PROBLEM 2 • “The spring of the cylinder retracts the piston that begins with moving upward.” ( Mechanical & Pneumatical Design Report, QinetiQ, 2009 ) QinetiQ space 18

1. PARKING MECHANISM PROBLEM 2 The hook has 2 degrees of freedom: a transitional movement of 40 mm and Upward/downward movement (+- 10 mm ) QinetiQ space 19

1. PARKING MECHANISM ALTERNATIVE 2 Proposal: we can use a kind of Cam shape. In this case the rod of the piston moves just in one direction (1 DOF). QinetiQ space 20

1. PARKING MECHANISM ALTERNATIVE 3 The more moving parts, the more possible problems (hinge joint, needle bearings) => Can we make a system which only translates? QinetiQ space 21

1. PARKING MECHANISM ALTERNATIVE 3 Problem: Need for a piston with a stroke of more than 150 mm (= stroke main cylinder) Norgren? QinetiQ space 22

2. EXIT PULLEY QinetiQ space 23

1. PARKING MECHANISM PURPOSE 2. EXIT PULLEY • Ensure the rope follows the movement of the astronaut on the treadmill. • Transfer the vertical – horizontal displacement into a vertical displacement. QinetiQ space 24

1. PARKING CONTENT MECHANISM 2. EXIT PULLEY 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dynamics calculation 2.5 Excentricity calculations 2.6 Alternative QinetiQ space 25

1. PARKING MECHANISM 2.1 Problem 2. EXIT PULLEY 2.1 Problem BEARINGS: lifetime GREASE: Lubrication – Type EXIT PULLEY: excentricity QinetiQ space 26

1. PARKING MECHANISM 2.2 Bearings. 2. EXIT PULLEY 2.1 Problem 2.2 Bearings Two types of bearings: • FAG-71806-B-TVH – Single row angular contact ball bearing • FAG-30-6-B-2Z-TVH. – Double row angular contact ball bearing – Cages: glass fibre reinforced polyamide QinetiQ space 27

1. PARKING MECHANISM 2.2 Bearings. 2. EXIT PULLEY 2.1 Problem 2.2 Bearings Lifetime calculation: • Static load rating – Properties which bearing must have to withstand loads during standstill. • Dynamic load rating – Describes during a certain number of revolutions certain mechanical loads under certain conditions. QinetiQ space 28

1. PARKING MECHANISM 2.2 Bearings. 2. EXIT PULLEY 2.1 Problem 2.2 Bearings Lifetime calculation: • Lifetime comparison according to NEN-ISO-281 Problem: • Radial and axial force on the bearing unknown QinetiQ space 29

1. PARKING MECHANISM 2.3 Grease. 2. EXIT PULLEY 2.1 Problem 2.2 Bearings 2.3 Grease • Lithium based grease – Separated in vacuum • Silicon based grease – Higher evaporation value QinetiQ space 30

1. PARKING MECHANISM 2.3 Grease. 2. EXIT PULLEY 2.1 Problem 2.2 Bearings 2.3 Grease Krytox 240AC • A high vacuum grease (up to 10 -16 bar). • Functionates in both extremely high and low temperatures (-15°C - 300°C) and in hostile environments. • Oxidation resistant. • Chemically inert • Offers needed lubrication properties QinetiQ space 31

1. PARKING MECHANISM 2.3 Grease. 2. EXIT PULLEY 2.1 Problem 2.2 Bearings 2.3 Grease LGET2 • A premium quality • A high vacuum grease (up to 10 -16 bar). • Functionates in both extremely high and low temperatures (-40°C - 260°C) • Excellent oxidation resistant. • synthetic ( fluorinated polyether ). • Very expensive. QinetiQ space 32

2.4 Dynamic calculation. 1. PARKING MECHANISM 2. EXIT PULLEY 2.1 Problem 2.2 Bearings • Purpose 2.3 Grease 2.4 Dynamic The pulley has to follow the oscillating calculation movement of the rope without slipping. If the inertia is too high there will be too much slip (heat generation) and extra wear of the rope so the life time is limited. QinetiQ space 33

1. PARKING MECHANISM 2.4 Dynamic calculation. 2. EXIT PULLEY • Forces on exit pulley 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dynamic calculation QinetiQ space 34

1. PARKING MECHANISM 2.4 Dynamic calculation. 2. EXIT PULLEY • Data 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dynamic calculation • Minimum tension in the rope 89 N. • The driving frequency 3Hz. • Hip movement of the running object. • Forward, backward ±30° • Upward, downward inclined maximum 10°. • Friction coefficient between rope and pulley =0,35 • Friction coefficient for the bearings = 0.002 • Preload 3N for pulley, 10N for swivel • Density of aluminum 2700 kg/m3 QinetiQ space 35

1. PARKING • Data MECHANISM 2. EXIT PULLEY 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dynamic calculation QinetiQ space 36

1. PARKING MECHANISM 2.4 Dynamic calculation. 2. EXIT PULLEY • Approximation of sine wave 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dyanmic calculation 100 90 80 Tension in the rope (N) 70 60 50 40 30 20 10 0 0 0,1 0,2 0,3 0,4 0,5 0,6 time (s) X 10 -3 QinetiQ space 37

1. PARKING MECHANISM 2.4 Dynamic calculation. 2. EXIT PULLEY • Equation of motion 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dyanmic calculation QinetiQ space 38

1. PARKING 2.4 Dynamic calculation. MECHANISM 2. EXIT PULLEY • Exit pulley 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dyanmic calculation 0,04 0,03 By taking the derivative 0,02 vertical displacement (m) 0,01 0 The second derivative 0 0,1 0,2 0,3 0,4 0,5 -0,01 -0,02 -0,03 The amplitude of the angular -0,04 acceleration can be calculated. time (s) QinetiQ space 39

1. PARKING MECHANISM 2.4 Dynamic calculation. 2. EXIT PULLEY • Mass moment of inertia 2.1 Problem 2.2 Bearings 2.3 Grease 2.4 Dyanmic calculation QinetiQ space 40

Recommend

More recommend