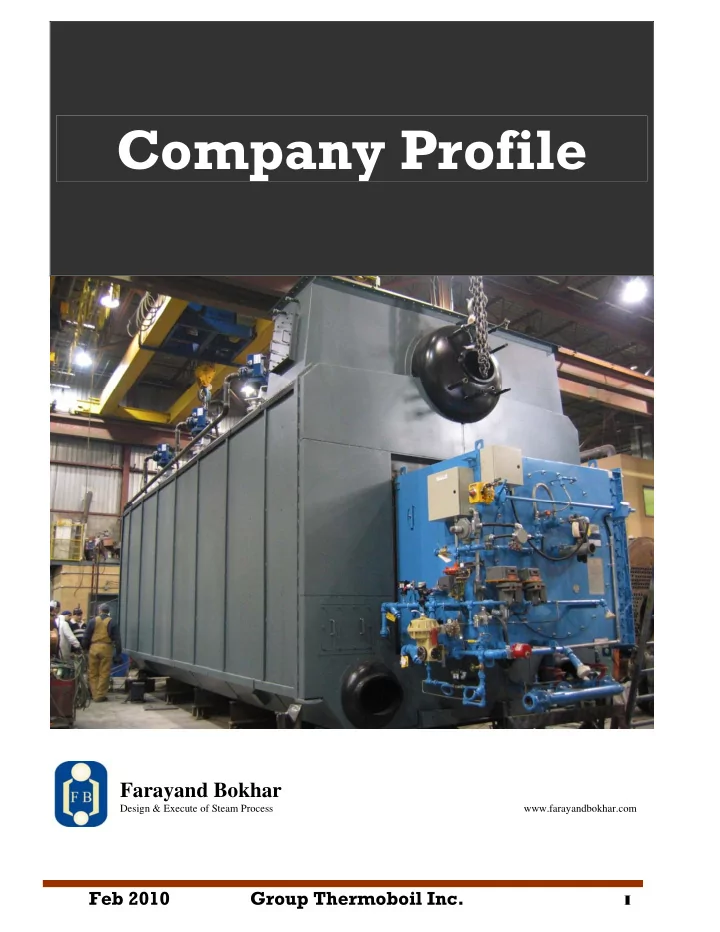

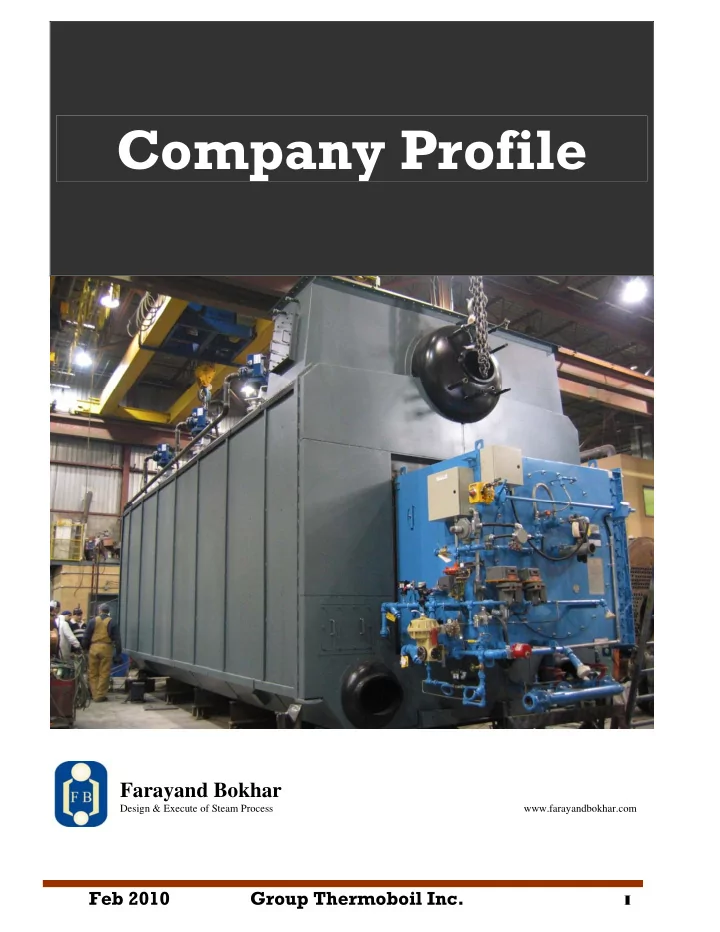

Company Profile Farayand Bokhar Design & Execute of Steam Process www.farayandbokhar.com Feb 2010 Group Thermoboil Inc. I

Contents Company Introduction Products Services Experience Contact us Feb 2010 Group Thermoboil Inc. II

Company Introduction About Us Group Thermoboil Inc. as the mother companyof Farayand Bokhar Co. is certified to perform field and shop fabrication of Pressure Vessels, fabrication and assembly of Power Boilers and Power Piping in accordance with the ASME Code. Our company is also certified for the field and shop repair and alterations of pressure retaining items in accordance with ASME Code and The National Board Inspection Code and Jurisdictional requirements. Our company employs ASME Code certified welders and has performed work using many different processes, to a large variety of materials. Having demonstrated competence to perform work within the scope of the ASME Code, Group Thermoboil Inc. has been certified with the following symbols: " U " for the field and shop fabrication of Pressure Vessels and Heat exchangers. " S " for the field and shop fabrication of Power Boilers. The Thermoboil – Farayand Bokhar team of engineering professionals has established a reputation for unmatched technical expertise in the field of watertube and firetube boilers, Deaerators and auxiliary equipments. Flexible and responsive to client needs, our problem-solving skills and customized approach are respected throughout plants worldwide. Group Thermoboil Inc. : USA-Canada-Europe-Australlia Farayand Bokhar Co.: Middle East-CIS countries- Africa-Asia Company project award in 2009-2010 : over 12 M- Euro Feb 2010 Group Thermoboil Inc. III

Company Introduction Key to customer satisfaction Strategy to ensure o ngo ing value added business Feb 2010 Group Thermoboil Inc. IV

Company Introduction Organization Chart Feb 2010 Group Thermoboil Inc. V

Products Boilers up to 250 t/h O-Type water tube boilers A-Type water tube boilers D-Type water tube boilers Feb 2010 Group Thermoboil Inc. VI

Products � Water tube � Fuel burned within combustion chamber � Combustion gas surrounds water tubes within vessel � Low water content allows rapid steam production � Capable of high pressure and superheated steam � Preferred ranges up to 250 t/h Feb 2010 Group Thermoboil Inc. VII

Products � Heat recovery steam generators (HRSGs) � Create steam using a heat exchanger in a hot gas flow • Turbine exhaust • Furnace exhaust � Can produce superheated steam � Can produce high pressure steam Feb 2010 Group Thermoboil Inc. VIII

Products Condensate Recovery System � � Steam traps � Collection tanks � Flash steam recovery � Pumps � Intermittent and continuous blow down tanks Feed Water System � � Deaerator up to 1400 t/h � Economizer Vertical dome Deaerators Horizontal dome Deaerators Feb 2010 Group Thermoboil Inc. IX

Products � Boiler auxiliary equipments � Stacks � Silencer � � � � � � � � � � � � Chemical Dosing Packages � Steam and water analyzing systems � Superheater � Heat recovery steam generator � DCS and control system Feb 2010 Group Thermoboil Inc. X

Products Chemical Dosing Packages for Boiler applications Feb 2010 Group Thermoboil Inc. XI

Services Services � Engineering and plants design � Steam process problem solution � After sale services � Boilers and Deaerators overhaul � Supply of raw material, parts and equipments SO, if you have: Boiler performance below target capacity High particulate carryover? Low boiler efficiency High carbon monoxide or TRS levels in the flue gas High levels of unburned carbon in the fly ash High moisture and/or high ash fuels High NOx emissions Inadequate water side circulation OR other steam and combustion problem, please CALL US Feb 2010 Group Thermoboil Inc. XII

Experiences Our references (2008 – 2010) Canada-USA W ill update soon. Middle East Azerbaijan Methanol Plant ( phase I I ) - steam package Design ,fabrication and commissioning of one unit of 60 t/ h water tube boiler and all other auxiliary equipment and DCS system as an EPC contract. Design of Methanol off-site piping system Azerbaijan Methanol Plant ( phase I ) – w ater treatem ents package Design ,fabrication and commissioning of 3 units if 150 m3/ h water treatment package Azerbaijan Methanol Plant ( phase I ) - steam package Design ,fabrication and commissioning of one unit of 60 t/ h water tube boiler and all other auxiliary equipment and DCS system as an EPC contract. Design of Methanol in-site process system piping National I ranian Oil Com pany – Abadan Refinery Design ,fabrication and commissioning of one unit of 45 T/ h deaerator National I ranian Oil Com pany - I ran Oil Term inals Design ,fabrication and commissioning of one unit of skid mounted condensate storage and pumping system National I ranian Oil Com pany - Naft Falat Ghareh Design ,fabrication and commissioning of one unit of 30 t/ h water tube steam boiler as per the ASME Sec I. (joint stock: Mashin Sazi Arak) Feb 2010 Group Thermoboil Inc. XIII

Experiences Atlasin Co. Procurement and fabrication of 22 units of Oxygen and Air pressure vessels as per the ASME Sec IIV Div I National I ranian Oil Com pany - I ran Oil Term inals Design, fabrication, installation and commissioning of 2 unit of 60 cu M/ h Deaeration system for Kharg Island water treatment plant including all process, mechanical, instrumentation, control system ,electrical and monitoring system. Basparan Petrochem ical Com pany • Fabrication of 8 horizontal filer vessels with the total weight of 80000 kg. • Fabrication of 6 vertical fitter vessels with the total weight of 30000 kg. These fitters use for filtering the inlet water going site cooling towers. All these vessels fabricated as per ASME CODE SEC III Div I. Torbat Sugar Factory • As the sub contractor of Nirou Pars Co. Installation and renovation of 100 T/ h, 60 T/ h, 45 T/ h, boilers and installation of new burners and all steam , gas and oil trains. Mobin Petrochemical Company (2004 future contract) • Supervision of 3 * 75 T/ h superheat A-type steam boiler installation Alborz Bulk Pharm aceutical Com pany • Design ,installation ,supervision and start up of 16T/ h boiler house • Design ,installation ,supervision of full factory piping • Reactors ,centrifuges and other equipments ,piping ( # 1 ) Azar Ghand Naghadeh Sugar Factory • Design and construction of 110 m3/ h Boiler feed water shell and tube Heat Exchanger • Design and construction of power plant heavy oil preheat Heat Exchanger ( # 2 ) Azar Ghand Naghadeh Sugar Factory • Design and fabrication of 11.3MW power plant piping • Installation of 50T/ h superheat steam Boiler equipments ,refractory and insulation • Burnet installation for 15 T/ h superheat steam Boiler • Installation and supervision for 35T/ h ,50T/ h and 15T/ h equipments installation to start up • 35T/ h and 15T/ h refractory and insulation fabrication • 15T/ h superheat steam Boiler internal drum piping Feb 2010 Group Thermoboil Inc. XIV

Certificates Am erican society of Mechanical Engineering S-stam p certificate of authorization S-stam p Certificate Of authorization ASME Feb 2010 Group Thermoboil Inc. XV

Certificates Certificate of Appreciation CASCADE-Canada Alberta Safety Association Construction Safety Cert. Feb 2010 Group Thermoboil Inc. XVI

Certificates Canadian W elding Association Quality Managem ent System Cert. Feb 2010 Group Thermoboil Inc. XVII

Certificates International consultants and contractors association Construction Certificate Feb 2010 Group Thermoboil Inc. XVIII

Recommend

More recommend