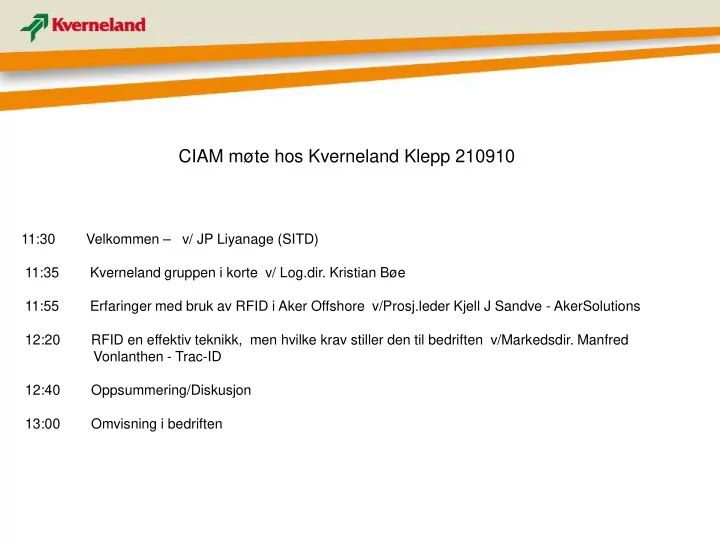

CIAM møte hos Kverneland Klepp 210910 11:30 Velkommen – v/ JP Liyanage (SITD) 11:35 Kverneland gruppen i korte v/ Log.dir. Kristian Bøe 11:55 Erfaringer med bruk av RFID i Aker Offshore v/Prosj.leder Kjell J Sandve - AkerSolutions 12:20 RFID en effektiv teknikk, men hvilke krav stiller den til bedriften v/Markedsdir. Manfred Vonlanthen - Trac-ID 12:40 Oppsummering/Diskusjon 13:00 Omvisning i bedriften

KvG Organization Structure CEO/COO Ingvald Løyning CFO Friedrich Pehle Administration SSC Group Finance IT/IS BA Arable BA Grass BA Arable BA After Sale Sales and BA Crop Care* Equip** Soil Equip.*** Plough Eq. **** Magne Marketing Anthony van der Anthony van Claus Wolfgang Svendsen Arild Gjerde Functional Responsibilities Ley Thomsen der Ley Kreienbaum Service Council Product Management Marketing/Branding/ Manufacturing Dealer Development Sourcing R&D Group functions Group Forecast to Cash Group IS/IT Group Finance and Controlling * Nieuw-Vennep ** Kerteminde, Gottmadingen, Mechatronics *** Soest, Modena, LLG ****Klepp, Lipetsk

Kverneland Group Global Presence 3

www.kverneland.com www.vicon.eu Visit us at: www.kvernelandgroup.com

BA Plough Equipment BA Ploug Equipment - Plougs Located in Klepp, Norway

BA Soil Equipment BA Arable Soil Equipment Located in Soest, Germany Seeders, Conservation Tillage, Harrows, Cultivators

BA Crop Care Equipment BA Crop Care Located in Nieuw-Vennep The Netherlands Sprayers and Spreaders

BA Grass Equipment BA Grass Equipment: Located in Kerteminde Denmark Forage, Bale and Feeding equipment KvG Mechatronics Located in Nieuw-Vennep The Netherlands

BA After Sales Central Distribution Centres: Metz (France) Klepp (Norway) Satellite warehouses: St. Helens (UK) Barcelona (Spain) Spare Parts Key numbers, 2008 Total turnover 110.600.000 EUR Number of unique articles: 220.000

Manufacturing Competence • Kverneland Group has 7 Manufacturing sites in 7 countries • Each manufacturing site specializes in specific products and is a dedicated competence centre with manufacturing, R&D and product management closely linked

Kverneland Group Precision Farming ISOBUS Implements Farm Management Software dGPS RTK ISO-XML

Plough Factories Klepp / Kvernaland Norway

Business Area Arable - Ploughing Equipment Managing Director Wolfgang Kreienbaum Business controller Trygve Martinsen Controlling IT/IS HR Manager Siv Iren Laland TBA Unn Birkeland R&D and Logistic Production Technical Service Sourcing Product Management Kristian Bøe John K. Tønnessen Egil Brastad Hansen Per K. Thomsen Joachim Wilms Sales & Marketing

Ole Gabriel Kverneland • Farmer’s son, Agricultural school • 1rst forge in 1879, aged 25 • Concept : production in large series (scythes&sickles) 1854 -1941 • Tooling : water powered spring hammer

Historical Milestones • 1879 forge • 1895 first extension, new building • 1952 first export (Finland) • 1962 first prize (World Plough Championship) • 1964 new & main factory in Klepp, tubular plough • 1983 Kverneland listed at the Oslo Stock Exchange • 1986 first diversification : Grass activities (KvU-Norway) • 1992-2009 several acquisitions and disvestments • 2009 Klepp new hall : + 2000 m2 Kvernaland forge - 1879 Kvernaland factory - 1895 Klepp - factory - 1965 Additional 2000 m2 - 2009

Core Competences Kverneland Klepp is a leader in its industry by its unique : • hardening processes • heat treatments of steel Competitive advantage based on : •good knowledge of farmers needs •use of advanced production solutions •strong partnership with important steel suppliers

• Kverneland steel unique and versatile Heat treatments • efficient and adapted (induction, carburising…) Forging • power, precision and Know how

Quality : Precise Combination of Automized / Manual production processes… Research & Development, Quality Control.

Forming, Forging & Hardening

CNC

R&D

Trainees

Welding

Historical Milestones : Products • 1992 Packomat • 1928 trailed plough for tractor • 1993 Packomat seeder • 1947 lifted plough for 3 point linkage • 2002 Ecomat • 1952 buckrake • 2003 semi-mounted plough • 1967 auto-reset System up to 14 furrows • 2007 new semi-mounted plough • 1971 reversible plough with Auto-Reset PW ”3 in 1” concept • 1971 reversible Point • 2009 launch of the new Rev. plough • 1981 Variomat System for light-medium soils • 2010 many more projects coming true 1947 2003 2009 Before 1928 1928

Key Figures • Turnover : 94 mill. euro • Worldwide sales : 45 countries • Production : 5.000 units • Factory : 72 000 m2 • Employees : 550

Need = Innovation = Kverneland Auto Reset Norwegian soil as the ice left it to us.

The world best plough

PW / RW introduction 2006 Semi-Mounted Reversible wagon plough up to 14 furrows

Global Kuhn KvG Lemken Markets Gregoire Besson European Pottinger Øverum Vogel & Noot National Rabe Unia - 1 000 2 000 3 000 4 000 5 000 6 000 Sales of ploughs Source: KvG team analysis and SOM database 2006

Produksjon / omsetning 2009 • Omsetning 2009: 802 mill NOK • Eksportandel ca. 95% 7 % Per hovedprodukt gruppe Plog 32 % Reserve-/slitedeler Other 61 % Per marked (plog) Other Finland France 17,7 % 2,9 % 15,2 % Polen Iberica 13,8 % 3,3 % Lithuania 3,4 % Germany 13,8 % BNL Denmark Sweeden 3,7 % UK 7,3 % 7,0 % 11,8 %

OMVISNING I FABRIKKEN • Takk for besøket og velkommen igjen!

Recommend

More recommend