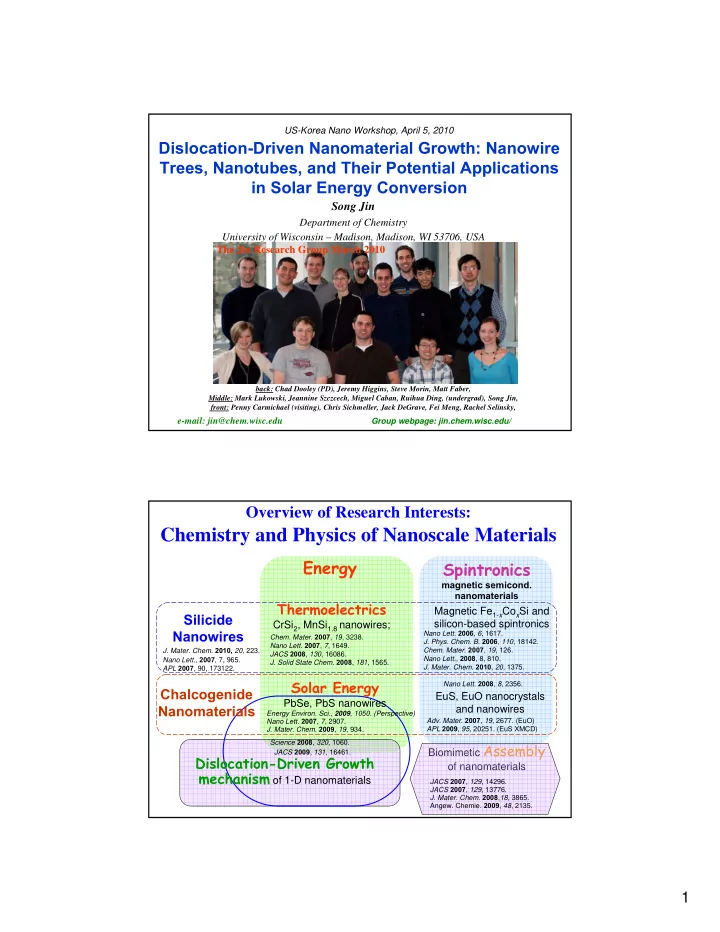

US-Korea Nano Workshop, April 5, 2010 Dislocation-Driven Nanomaterial Growth: Nanowire Trees, Nanotubes, and Their Potential Applications in Solar Energy Conversion Song Jin Department of Chemistry University of Wisconsin – Madison, Madison, WI 53706, USA The Jin Research Group March 2010 back: Chad Dooley (PD), Jeremy Higgins, Steve Morin, Matt Faber, Middle: Mark Lukowski, Jeannine Szczcech, Miguel Caban, Ruihua Ding, (undergrad), Song Jin, front: Penny Carmichael (visiting), Chris Sichmeller, Jack DeGrave, Fei Meng, Rachel Selinsky, e-mail: jin@chem.wisc.edu Group webpage: jin.chem.wisc.edu/ Overview of Research Interests: Chemistry and Physics of Nanoscale Materials Energy Spintronics magnetic semicond. nanomaterials Thermoelectrics Magnetic Fe 1- x Co x Si and Silicide silicon-based spintronics CrSi 2 , MnSi 1.8 nanowires; Nanowires Nano Lett. 2006 , 6 , 1617. Chem. Mater. 2007 , 19 , 3238. J. Phys. Chem. B . 2006 , 110 , 18142. Nano Lett. 2007 , 7 , 1649. J. Mater. Chem. 2010, 20, 223. Chem. Mater. 2007 , 19 , 126. JACS 2008 , 130 , 16086. Nano Lett., 2008 , 8, 810. Nano Lett., 2007 , 7, 965. J. Solid State Chem. 2008 , 181 , 1565. J. Mater. Chem. 2010 , 20 , 1375. APL 2007 , 90, 173122. Solar Energy Nano Lett. 2008 , 8 , 2356. Chalcogenide EuS, EuO nanocrystals PbSe, PbS nanowires Nanomaterials and nanowires Energy Environ. Sci., 2009 , 1050. (Perspective) Nano Lett. 2007 , 7 , 2907. Adv. Mater. 2007 , 19 , 2677. (EuO) J. Mater. Chem. 2009 , 19 , 934. APL 2009 , 95 , 20251. (EuS XMCD) Science 2008 , 320 , 1060. Biomimetic Assembly JACS 2009 , 131 , 16461. Dislocation-Driven Growth of nanomaterials mechanism of 1-D nanomaterials JACS 2007 , 129 , 14296. JACS 2007 , 129 , 13776. J. Mater. Chem. 2008 , 18 , 3865. Angew. Chemie. 2009 , 48 , 2135. 1

Nanowires for Solar Energy Conversion Caltech Harvard Nature 2007 PV PEC Berkeley JACS 2008 Caltech JACS 2007 Science 2010 PSU JACS 2007 photovoltaics, photoelectrolysis, Other applications in energy: thermoelectrics, battery electrodes Vapor-Liquid-Solid Nanowire Growth reactant 1-d growth nucleation gold nanocatalyst reactant Vapor-Liquid-Solid growth Δ SiH 4 Si + 2 H 2 SEM image TEM image HRTEM image AuSi nano-alloy AuSi nano-alloy Supersaturation 10 μ m SiNW 5 nm Gold Nucleation Nanoparticle Using Silicon nanowires as examples Morales & Lieber, Science 279 , 208 (1998) Cui et al., Appl. Phys. Lett. 78 , 2214 (2001) Using Silicon nanowires as examples Wagner & Ellis Appl. Phys. Lett. (1964). 2

A New Twist on Nanowire Formation See Science 2008 , 320 , 1060 for details. Jin Research Group jin.chem.wisc.edu Forest of PbS Nanowire “X-mas Trees” These nanowire tree structures demonstrate an entirely different nanowire growth mechanism that is driven by screw dislocations. 100 μ m 3

A Primer on Dislocations Edge dislocation Burgers vector (b): The displacement vector to close a lattice circuit Edge dislocation: Burgers vector ⊥ line of cut Screw Dislocation: Burgers vector // line of cut Dislocation&Crystal Growth: Frank ’ s Mechanism Idealized layer-by-layer crystal growth on perfect crystals 1930s Kossel, Stranski, Becker & Doring, Gibbs 1949 & 1951, Sir F. Charles Frank (1911-1998) , a self-perpetual step for adding new layers in crystal growth – screw dislocations cause “growth spirals” Growth Spirals observed on crystal faces Burton, Cabrera & Frank, Philos. Trans. R. Soc. London A, 1951 , 243 , 299. 4

Dislocation & 1-D Anisotropic Crystal Growth a self-perpetual step for adding new layers for crystal growth at low supersaturation! √ × × Tree Nanowires – combination of fast 1-D anisotropic crystal growth! -- dislocation-driven trunk NW growth and whiskers, nanowires… slower VLS growth of branch NWs DCTEM Observation of Screw Dislocations in PbS X-mas Tree NWs A B C D E F Bierman, Lau, … & Jin Science 2008, 320 , 1060. 5

“Eshelby Twist” Strain associated with screw dislocation Bierman, Lau & Jin Science 2008, 320 , 1060. Screw dislocation, if no opposite torque is applied at its ends b α = π 2 R J.D. Eshelby. Screw dislocations in thin rods. J. Appl. Phys. 24 , 1953 , 176-179. II. Screw dislocation driven growth of 1D nanomaterials is general to both vapor phase and solution phase growth 6

Aqueous Solution Growth of ZnO Nanowires/tubes High density, high aspect ratio, thin ZnO nanowires � Most popular route: Aqueous hydrolysis of zinc nitrate with hexamethylenetetramine (HMT) � Generates low aspect ratio nanowires/rods. 1 μ m � We overcome this problem by targeting low supersaturation growth conditions that promote dislocation driven growth. 10 μ m 2 μ m Morphology Change with Supersaturation c Axis Growth Morin, Bierman, Tong & Jin in press Science, 2010. 7

Kinetics of Crystal Growth Experimentally determined growth rates vs. rate laws predicted by theory: Prove screw dislocation driven crystal growth! Morin, Bierman, Tong & Jin in press Science, 2010. Dislocations in ZnO Nanowires/Nanotubes • Diffraction contrast TEM show dislocation with screw component along (001) • Axial dislocations in NWs drives growth • Single-crystal hollow nanotubes! lattice continuous across tube Morin, Bierman, Tong &Jin submitted B, C F 8

Hollow Nanotubes: Open Core Dislocations Dislocations contain elastic energy proportional to b 2 : μ R = 2 E ln( ) b π 4 r r a large value of b lead to a “hollow core dislocation” R (F. C. Frank, Acta Crystallogr. 1951 , 4, 497) • Core materials removed to alleviate the strain energy; • Balanced by surface energy of the new internal surface: μ 2 b r = π γ 2 8 μ -- shear modulus γ -- surface energy Guggenheim Museum, New York “Dislocation micropipes” in solid crystals and thin films (SiC, GaN, etc) To Twist or Not to Twist: Re-Examine the Energy Equations Two pathways to relieve strain energy: μ μ − 2 2 2 2 b R b ( R r ) = πγ + − E 2 r ln( ) π π + 2 2 4 r 4 ( R r ) π γ + 2 2 2 dE 8 r R r = → = 0 b * μ − TOTAL 2 2 dr R r • New energy minimization: hollowing out at small b ; Eshelby twist at large b. π γ ⎛ + ⎞ 2 2 2 8 r R r = − = ⎜ − ⎟ b b b 1 ⎜ ⎟ μ − TWIST TOTAL TUBE 2 2 ⎝ ⎠ R r • Twist vs. hollow at different r/R: thick tubes have little twist, thin-walled tubes have twist. Energy Minimization � b= 1.3 nm Direct Measurement � b= 1.9 nm Morin, Bierman, & Jin in press Science, 2010. 9

Complex Nanowires for Solar Energy Conversion 1) Complex branching structures D potentially useful for solar energy harvesting and carrier collection • Dendritic structures good for solar energy harvesting and carrier collection Nanoscale heterostructures allow more • 20 µm 20 µm 20 µm diverse materials Bierman & Jin, Epitaxial growth on TiO 2 , NaCl, mica (invited perspective) 2009, 2 , 1050. Lau, …, & Jin J. Mater. Chem. 2009 , 19 , 934. Solution Grown Nanomaterials of Inexpensive Semiconductors for Solar Energy Conversion Solution grown ZnO nanotube Dislocation-driven nanowire growth has advantages over VLS growth for large scale applications of nanomaterials for energy. – No metal catalysts, – vapor or solution phase growth – Aqueous solution growth better for large scale synthesis! – Heterojunctions by simple solution synthesis? e.g. Fe 2 O 3 - TiO 2 For example, solar energy from Fe 2 O 3 NWs? Fe 2 O 3 nanowires • Hematite is a poor semiconductor (E g = 2.1 eV) • Cheap, stable in aqueous solutions, promising for photocatalysis • Nanowires might circumvent the problems • How to construct solar devices with rust nanowires? 2 μ m On going – Mark Lukowski, Miguel Caban, Fei Meng, Matt Faber 10

Significance of the Discoveries � a “new” nanowire growth mechanism driven by screw dislocations � Clear demonstration of the Eshelby twist � Spontaneous formation of single-crystal nanotubes driven by screw dislocations � General to 1-D growth of many materials, vapor or solution growth, such as: � ZnO, PbQ (we have proven herein) � InN, GaN, Te, SnO 2 , etc (seen in literature) � SiC, CdS, CdSe, etc. � Used classic crystal growth theory to conclusively prove dislocation-driven growth � Complex NW structures useful for solar energy conversion � Large scale, low cost synthesis of NW materials Unanswered questions and future work: • How does the screw dislocation originate? • The perfect platform for investigating the effects of a single dislocation on material properties. 11

Recommend

More recommend