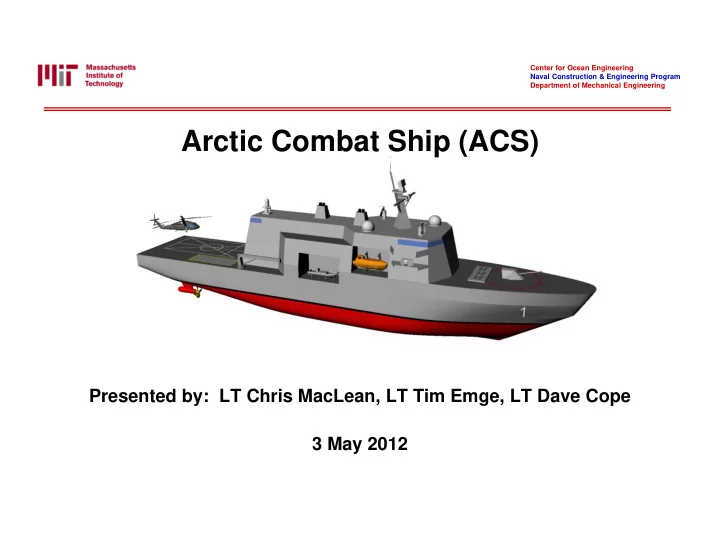

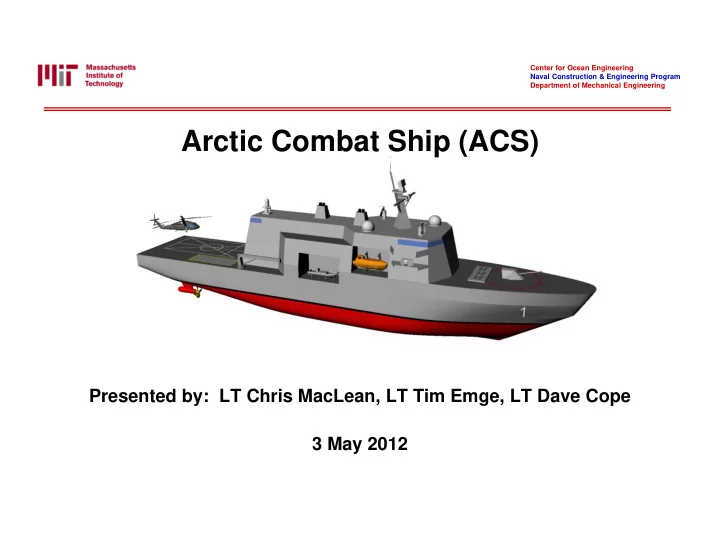

Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering Arctic Combat Ship (ACS) Presented by: LT Chris MacLean, LT Tim Emge, LT Dave Cope 3 May 2012

Sponsors Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering • Dr. Norbert Doerry – Technical Director for NAVSEA 05T • Mike Bosworth – Deputy Chief Technology Officer NAVSEA 05T 1 May 2012 ACS 2

Threat and Operational Center for Ocean Engineering Naval Construction & Engineering Program Environment Department of Mechanical Engineering • Arctic ice diminished summers by 2030 – Increased commercial shipping, resource development, tourism, environmental interest, strategic focus (Oil/Gas) • 2 key drivers of uncertainty: – Resources/trade – Governance • UNCLOS – Regulates claims beyond the EEZ – Russian extension of continental shelf beyond 200 NM EEZ • Planted a flag below North Pole – U.S. has not ratified • 2 Coastal Passages – Northwest Passage – international strait vs. Canadian inland waters – Northern Sea Route – 5000 NM shorter than Suez Canal • Chinese claim to resources – No national sovereignty over Arctic – One-fifth of world’s population, equal claim to gas/oil 1 May 2012 ACS 3

Threat and Operational Center for Ocean Engineering Naval Construction & Engineering Program Environment Department of Mechanical Engineering 1 May 2012 ACS 4

Background Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering • Post WWII Operation Deep Freeze – Requirement for heavy icebreakers – Wind Class-USCG/USN/CCG/USSR – USN operated until 1966, then transferred to USCG 1 May 2012 ACS 5

Technical Background Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering Norway Canada 1 May 2012 ACS 6

Missions Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering • Major Mission Areas (Known-knowns) – Information, Surveillance and Reconnaissance (ISR) – Maritime Interdiction (MIO) – Humanitarian Assistance & Disaster Response (HADR) – Search & Rescue (SAR) • Inherent Modularity (Reconfigurable spaces) – Research/Exploration (oceanographic & meteorological) – Command and Control – Medical – Autonomous/Manned Vehicles • Future Allowance (Known-unknowns) – Ballistic Missile Defense (BMD) – Anti-Submarine Warfare (ASW) – Anti-Air Warfare (AAW) 1 May 2012 ACS 7

Design Philosophy Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering • Persistent presence in the Arctic • Design for the environment – Supplement Navy Standards with ABS Requirements for Polar Class Vessels • Special consideration for hull structure, propeller, and machinery • Maintain Navy margins and survivability – Extended on-station time • Balance capability with cost – Presence first, then as much added capability as possible without increasing cost beyond roughly $1B FY11 • Risk will be minimized to a level appropriate for an IOC of FY20 – Minimize new technologies to avoid cost increases 1 May 2012 ACS 8

Final Design Center for Ocean Engineering Naval Construction & Engineering Program Characteristics Department of Mechanical Engineering Parameter Value LBP 345.5 feet Beam 65.5 feet Draft 20 feet Depth (Station 10) 50 feet Prismatic 0.625 Coefficient Lightship 5,357 Long Tons Displacement Full Load 7,046 Long Tons Displacement GM t /B 0.141 Polar Class 4 Endurance 150 Days Range 17,560 nautical miles Maximum Speed 19.7 knots Sustained Speed 18.0 knots Lead Ship Cost $1.27 Billion (FY11) Follow Ship Cost $977 Million (FY11) Crew 124 1 May 2012 9 Accommodations 156

Final Design Payload Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering – Aviation: 2 MH-60R Helos – Small Vehicles: 2 RHIBs/1 HC or 1LC – Modularity: 10 TEU – Gun: MK 110 57mm – Crane: 1 30-Ton – VLS: 24 cells 1 May 2012 ACS 10

Polar Class 4 Operational Center for Ocean Engineering Naval Construction & Engineering Program Limits in 2020 Department of Mechanical Engineering 1 May 2012 ACS 11

Engineering Plant Design Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering • Azipods becoming preferred drive method – Increased maneuverability – Less susceptible to drive damage from ice impacts • Diesel Electric most common plant on ice class vessels • Conducted in-depth analysis of non-integrated electric drive vs. Integrated Power System • Ratio SS to Propulsion Power near 1:1 – Propulsion power requirement like another load • Results showed that IPS provides – Higher efficiency, therefore less tankage – Fewer engines 1 May 2012 ACS 12

Propeller Design Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering 1 May 2012 ACS 13

Hull Design Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering 1 May 2012 ACS 14

Polar Class Structural Center for Ocean Engineering Naval Construction & Engineering Program Optimization Department of Mechanical Engineering • ABS Structural Requirements for Polar Class Vessels • Tool optimizes for minimal ice strengthened structure weight – Outputs: plate thickness, frame, and stringer sizes/spacing • Verified by comparison to USCGC Polar Star structural weight • Led to section design and hull girder strength analysis σ allowable >> σ calculated 1 May 2012 ACS 15

Slide 15 T1 Need to make the scale legible Tim, 4/18/2012

Arrangements Design Center for Ocean Engineering Naval Construction & Engineering Program Drivers Department of Mechanical Engineering • ABS and Canadian Arctic Shipping Pollution Regulations require no fuel in contact with skin of the ship, i.e. double bottom, for new builds • Ice Class Azipod produced by ABB, G=5.0m • Large capacity crane and elevator for Mission Bay loading/unloading 1 May 2012 ACS 16

Arrangements Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering AP MS FP 1 May 2012 ACS 17

Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering MS FP AP 1 May 2012 ACS 18

Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering AP MS FP 1 May 2012 ACS 19

Zonal Electrical Center for Ocean Engineering Naval Construction & Engineering Program Distribution Department of Mechanical Engineering 1 May 2012 ACS 20

Key 4.16 kV Bus Power Conversion Module PCM PCM Power Distribution Module PDM Loads PDM PDM Deckhouse Loads PGM Power Generation Module PCM Shore Power SP Zone 6 Zone 7 Azipod Propulsion Motor Module Zone 3 Zone 2 Zone 4 Zone 5 Zone 1 PCM PCM Loads Loads PDM PDM PDM PCM PGM PGM Hull PDM PDM SP PDM PDM PGM PGM PDM PCM Loads Loads Loads PCM PCM PCM AFT FWD

Conclusions Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering • No US Navy Precedent • Model Testing Imperative • Cost ~1 Billion Dollars • Feasible • Presence with Modularity/Margins (Reconfigurable spaces, VDS/Aegis) • Low Risk • Possible USCG conversion 1 May 2012 ACS 22

Questions Center for Ocean Engineering Naval Construction & Engineering Program Department of Mechanical Engineering Parameter Value LBP 345.5 feet Beam 65.5 feet Draft 20 feet Depth (Station 10) 50 feet Prismatic Coefficient 0.625 Lightship Displacement 5,357 Long Tons Full Load Displacement 7,046 Long Tons GM t /B 0.141 Range 17,560 nautical miles Maximum Speed 19.7 knots Sustained Speed 18.0 knots Lead Ship Cost $1.27 Billion (FY11) Follow Ship Cost $977 Million (FY11) Crew 124 Accommodations 156 1 May 2012 ACS 23

Recommend

More recommend