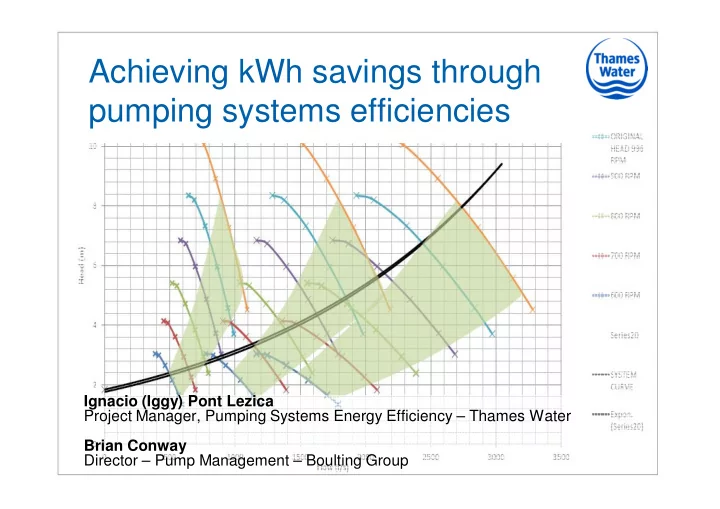

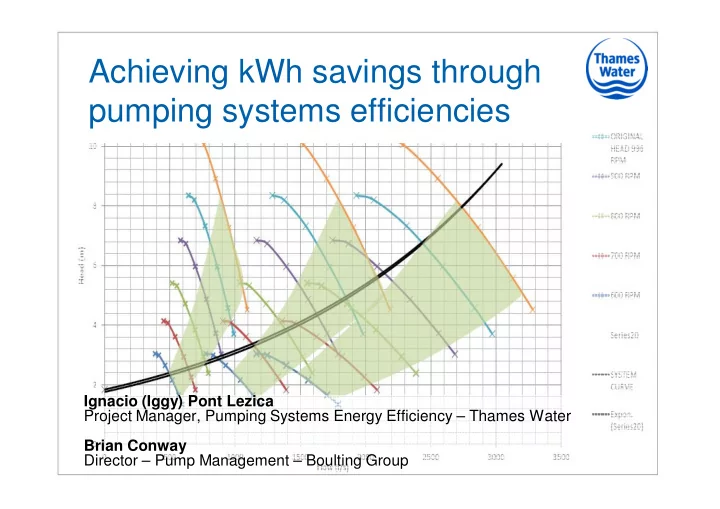

Achieving kWh savings through pumping systems efficiencies Ignacio (Iggy) Pont Lezica Project Manager, Pumping Systems Energy Efficiency – Thames Water Brian Conway Director – Pump Management – Boulting Group

Synopsis � Soaring energy costs and regulatory drivers have placed energy efficiency high on the agenda in the water industry. Within annual energy budget of close to £ 100 million, and pumping accounting for approximately 65% of this, there is an obvious case for achieving efficiencies through better pumping. In this presentation we will show the methodology employed, talk about some of the types of opportunities found, and give some examples of what has been achieved. 2

Introduction � Drivers behind pumping efficiencies programme � How this is being delivered � Examples

Background � TW spends close to £100m on energy � Pumping accounts for 65% of this figure � Regulatory drive to reduce energy consumption � Benefit for the company (bottom line and brand) � TW target goes beyond Ofwat regulatory target (in line with UK targets) – 20% reduction in energy use by 2015 based on 1990 levels 4

Process � Business case put forward to the investment committee � Lump sum was allocated to the project based on estimated savings – no specific sites or solutions were identified � Framework contract was put out to tender 5

Working in partnership � Framework based on accuracy of savings identified vs savings delivered – gives confidence in the project � Initial teething issues, in particular understanding how different geographical areas of the company operate in different ways � Some initial resistance based on pumping misconceptions � Open contractual approach to targets and delivery options 6

Methodology Shortlist sites Overview based on yearly kW consumption Desktop Study and local knowledge Test Analyse Selection of solutions based on Report kWh savings and ROI, to date ROI Recommend has been as short as 0m, and savings Implement as large as 1.4gWh/year Validate Monitor 7

Measurement SEC – Specific Energy Consumption � What is it – Provides a means of performance standardisation for all Pump Stations � Units – kWh/Ml (energy used per Megalitre transferred) – kWh/Ml/m (energy used per Megalitre transferred per metre of system head) 8

Sample Recommendations � Ashford LLPS - East (reinstate siphonic recovery, PLC control) � King George V (manual modification and operator training based on SEC) � Kempton HLPS (Impeller trim, pump refurbishment and operator training) � Hampton low lift (new motor + VSD + PSOp™) � Cricklewood / Shortlands (new motor + VSD + change of control philosophy) � Littleton RWPS (pump refurbishment or replace pumps) � North Leigh BPS (PSOp™ implementation in to PLC/SCADA) � Swinford Dam RWPS (PSOp™ implementation in to PLC/SCADA) 9

Worked examples � Swinford Dam RWPS � Ashford Low Lift East PS � Swinford North Leigh BPS 10

Swinford – North Leigh BPS � Transfer from Beacon Hill SR to North Leigh SR – Average 25Mld transfer rate – Approx 35% system friction – 3 pumps (duty/assist/standby) – Equipment in good condition – All installed with VSD – Demand input from Control Centre based on North Leigh reservoir level 11

Swinford – North Leigh BPS � Details provided in Conference Presentation – Please contact presenter for full details 12

Swinford – Dam RWPS � Transfer from Farmoor Reservoir to Swinford WTW – Average 65Mld transfer rate – Up to 60Mld by gravity (dependant on reservoir level) – 2 pumps (duty/standby) – Equipment in good condition – All installed with VSD – Demand input from WTW with manual control – Needs to maintain level in main intake sump to WTW 13

Swinford Dam RWPS � Details provided in Conference Presentation – Please contact presenter for full details 14

Ashford Common WTW - LLPS � Transfer of filtered water to contact tanks – Average daily capacity approx 550Mld – Capacity controlled by maintaining sump level – 2 sumps, each with 4 pumps – 2 discharge mains to contact tanks – All pumps fitted with VSDs (ageing) – Pumps installed with discharge siphon 15

Ashford Common WTW - LLPS � Details provided in Conference Presentation – Please contact presenter for full details 16

Summary � Lots of savings to be found in pumping systems � Big challenges ahead � Working together achieves the best results

Contact Details Brian Conway Iggy Pont Lezica Boulting Group Ltd Thames Water Utilities Ltd Chapel Road Clearwater Court Penketh Vastern Road Warrington WA5 2PL Reading, RG1 8DB Tel. 01925 446000 Mob. 077 476 42318 Mob. 07736 628996 E-mail ipl@thameswater.co.uk E-mail brianconway@boulting.co.uk Web www.boulting.co.uk 18

Recommend

More recommend