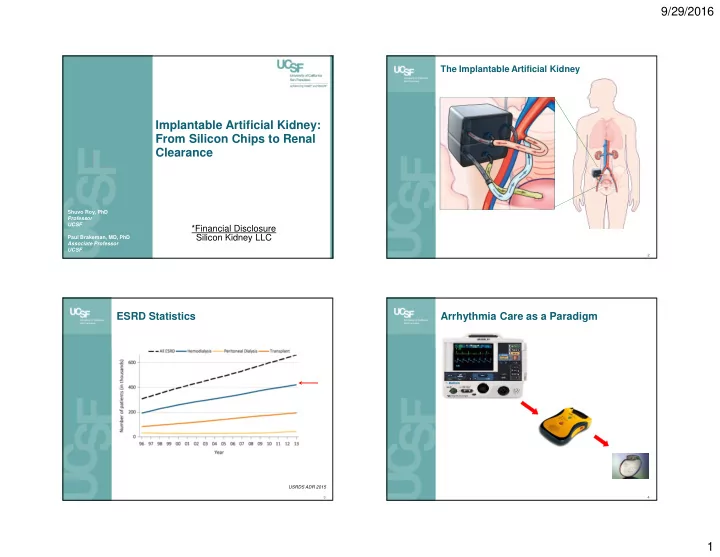

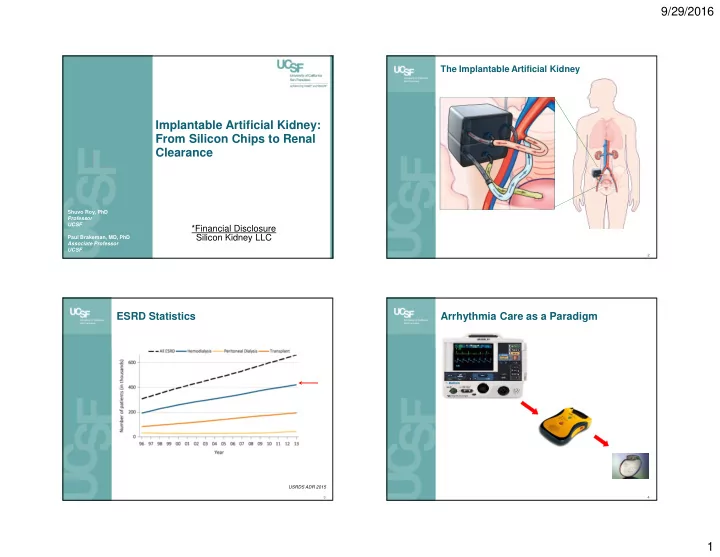

9/29/2016 The Implantable Artificial Kidney Implantable Artificial Kidney: From Silicon Chips to Renal Clearance Shuvo Roy, PhD Professor UCSF *Financial Disclosure Silicon Kidney LLC Paul Brakeman, MD, PhD Associate Professor UCSF 2 ESRD Statistics Arrhythmia Care as a Paradigm USRDS ADR 2015 3 4 1

9/29/2016 Application to Renal Replacement Application to Renal Replacement Implantable ? Artificial Kidney 5 6 The Renal Filter Unit: the Nephron The Renal Filter Unit: the Nephron Distal Distal Glomerulus Glomerulus Tubule Tubule Proximal Proximal Tubule Tubule Glomerulus ~500,000-1,000,000 per kidney Generate ~150L of filtrate per day Collecting Collecting Duct Duct Loop of Loop of Henle Henle 2

9/29/2016 Solution - Implantable Artificial Kidney The Renal Filter Unit: the Nephron Distal Glomerulus Tubule Proximal Tubule Renal Tubule Selectively reabsorbs ~99% of most solutes Reabsorbs ~99% of filtered water Collecting Most reabsorption occurs in the proximal tubule Duct Loop of Henle 10 Renal Assist Device RAD Human Trial Results • Phase II, multicenter, randomized trial with 58 Hemofilter patients in the ICU – 50% reduction in mortality for patients treated with the RAD versus conventional therapy Bioreactor Tumlin J et al. Efficacy and Safety of Renal Tubule Cell Therapy for Acute Renal Failure. JASN 2008 19: 923 11 12 3

9/29/2016 Application to Renal Replacement Key Target Specifications • Package size no larger than 750 ml – no pumps • Solute clearance of 20 ml/min (~20% of normal function) – membrane hydraulic permeability of 10 ml/min/mmHg/m 2 – ~30 liters of filtrate produced per day • Selective filtration – Albumin loss of 3-4 G per day (membrane sieving coefficient of 0.025) • Fluid excretion of about 3-5 liters/day – Requires reabsorption rate of 3 mmol/min Na + in bioreactor – translates to ~25 liters of filtrate reabsorbed per day 13 Optimizing Water Transport The Renal Filter Unit: the Nephron Distal Glomerulus Tubule Proximal Tubule Renal Tubule Selectively reabsorbs ~99% of most solutes Reabsorbs ~99% of filtered water Collecting Most reabsorption occurs in the proximal tubule Duct Loop of Henle 4

9/29/2016 Optimizing Water Transport – Shear Flow Optimizing Water Transport – Shear Flow Water Transport (LL-PCK1) 140 Transport in uL/cm2/day 120 100 80 60 40 • Bioreactor features 20 – Microchannel for controlled shear stress on apical surface 0 0.02 0.2 0.5 2 of cells Shear Flow in Dyne/cm2 – Corning Snapwell membrane for cell support and transport pathway – Access to basal surface of cells for sampling Cell Growth The Renal Filter Unit: the Nephron • Human renal tubule cells (HRTCs) – reliable isolation and expansion protocols – 1 gm of biopsy tissue (10 8-10 cells) for 17 doublings • Successful cryopreservation and functional longevity – 4+ months in liquid nitrogen Distal Glomerulus – 6+ month cell viability in perfusion circuit Tubule Proximal Tubule HRTC on Under Shear 4-month Cell Viability Flow Glomerular Filtration ~500,000-1,000,000 per kidney Generate ~150L of filtrate per day Collecting Duct Loop of Henle 19 5

9/29/2016 Filtration is a Fundamental Barrier to Silicon Microfabrication Miniaturization • Current hollow-fiber filtration membranes have major limitations – thick porous polymer films have non-uniform pore sizes and degrade over time upon exposure to body fluids TEM – Glomerulus SEM – Polymer Membrane Precision patterning tools to enable high volume manufacturing of semiconductor devices 21 22 Completed Wafer Membranes Characteristics • High hydraulic permeability – up to 600 ml/hr/mmHg/m 2 • no pump needed • Manufacturing compatibility Each chip contains – scalable for larger quantities over 10,000/cm 2 rectangular 60 um x 120 um membranes 23 24 6

9/29/2016 First Implanted Silicon Nanopore Biocompatibility Coatings to Prevent Membrane Hemofilter Thrombosis • Evaluation of 3 coatings for protein resistance Kensinger et al. ASAIO J 2016 – polyethylene glycol (PEG) is widely used – poly(N-vinyldextran aldonamide-co-N-vinylhexanamide) (PVAm) • synthetic glycocalyx – polysulfobetaine methacrylate (polySBMA) • zwitterionic polymer 60 PEG PVAm 50 polySBMA 40 Fg Adsorption, % 30 20 10 0 Day 1 Day 7 Day 21 Day 28 -10 Ultrafiltrate 1 x 1cm SNM 25 26 Titanium Hemofilter Prototype First Implanted Silicon Nanopore Dimensions: 9.3cm x 5.7cm x 1.4cm Membrane Hemofilter Ultrafiltrate Ports Filtrate Volume 8 Ultrafiltrate Ports 7 6 ml/cm 2 /day 5 4 3 2 3mm Blood Outlet 1 0 1 2 3 4 5 Device 3mm Blood Inlet Adapted from Kensinger et al. ASAIO J 2016 28 7

9/29/2016 Individual Channel Hemofilter Assembly 3.2cm 6.5cm Top Plate Assembled Subunits Blood outlet Nanopore Region Seal Plate Blood Outlet Bottom Plate Blood Inlet Blood inlet: 1mm channel height 29 30 Whole Porcine Blood Bench Top Experiments Explant: Post-Operative Day 3 (POD3) Pump Thrombus Inlet Blood Reservoir Outlet 31 32 8

9/29/2016 Device Placed in Retroperitoneum Arterial Inflow (Dacron Graft) Venous Outflow (Dacron Graft) 33 34 Surgical Considerations for Surgical Considerations for Implantation Implantation • Housing material • Housing material and geometry and geometry • Device weight • Device weight • Vascular • Vascular interface interface 35 36 9

9/29/2016 Surgical Considerations for Device Housing Modification • Housing Redesign Implantation – 40% lighter by using Polyether ether ketone (PEEK) – Anchoring points • Housing material incorporated into new and geometry PEEK plates Anchor points • Device weight – \ • Vascular interface Titanium PEEK 37 38 Graft Connector Modifications Vascular Connector Design: • New Synthetic graft – More rigid material for the tubing with external support rings • Strain-relieving Sleeve – External support to provide structural rigidity at the titanium-graft interface 39 40 10

9/29/2016 Intraoperative positioning of modified prototype Modified Vascular Interface Device Anchors Aorta Anastomosis to Aorta External Iliac Vein Strain-relief 41 42 Selective angiogram prior to explant on POD3 Key Phase I Accomplishments • Cell bioreactor Catheter tip – reliable cell sourcing and expansion In Inflow graft – successful cryopreservation – active water reabsorption • Hemofiltration – high hydraulic permeability – high permselectivity – multichannel, large scale hemofilter implanted for up to 3 days • FDA Innovation Pathway 2.0 – CDRH program to shorten time-to-market – goal is to shorten time-to-market without sacrificing safety Outflow graft 43 44 11

9/29/2016 Key Phase 2 Design Targets Acknowledgements • Collaborators • Cell bioreactor – The Kidney Project team – Scale up of bioreactor for macroscopic filtrate reabsorption – FDA CDRH • Hemofiltration Longer scale implantation – UCSF Pediatric Device Consortium – Optimization of porosity for increased hemofiltration – UCSF Surgical Accelerator • FDA Innovation Pathway 2.0 – UCSF Clinical Translational Sciences Institute (CTSI) – CDRH program to shorten time-to-market • Funding – goal is to shorten time-to-market without sacrificing safety – NIH: R01 EB014315; R01 EB008049; R21 EB002285; K08 EB003468 – DoD: W81XWH-05-2-0010 – NASA: JGBEC – Rogers Bridging-the-Gap Award – Hinds Distinguished Professorship II – Goldman Family Foundation – Wildwood Foundation 45 46 Roy Lab 47 12

Recommend

More recommend