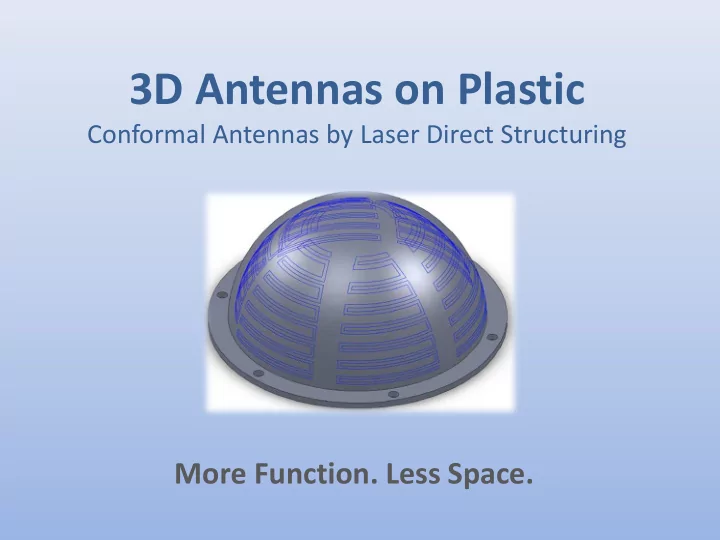

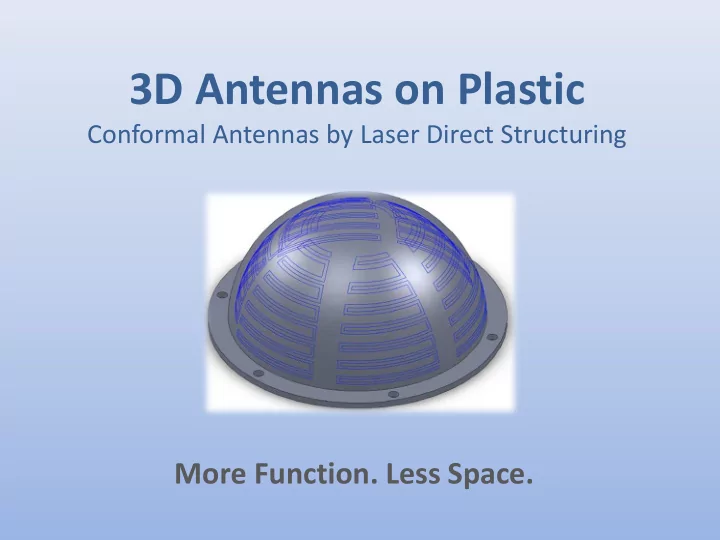

3D Antennas on Plastic Conformal Antennas by Laser Direct Structuring More Function. Less Space.

Host Josh Brown Marketing Development LPKF Laser & Electronics Presenter Jim Liddle Director, Business Development and Marketing SelectConnect Technologies

LDS Design Guidelines Design_Guidelines.pdf

Questions

LDS 3D - More into Less

Antenna Challenges

Shall we begin?

Techology Evoltuion

LDS Solutions

LDS Process Metalized part Components attachment Injection molded part Laser marked part

LDS Solutions

3D-MID Source: Kromberg & Schubert GmbH & Co. KG Source: KaVo Dental Source: Aktiv Sensor GmbH Source: VTI Oy

3D-MID Source: Kromberg & Schubert GmbH & Co. KG

3D-MID Source: Kromberg & Schubert GmbH & Co. KG

3D-MID Source: KaVo Dental

3D-MID Source: Aktiv Sensor GmbH Source: VTI Oy

…Circa

LDS Production Markets 77 75 2010 2009 26 2 3 8 Fusion Microline

Market Opportunity

True 3D Circuitry

LDS Antenna Future Source: Pulse

LDS Process for Conformal Antenna

LDS 3-D Process

LDS Grade Materials Dielectric Melt temp, F 4.0 660° LCP 498° PBT 3.0 PC/ABS COP 320° Amorphous Semi-crystalline

CAD to Part

LDS Technical Summary

Laser Activation of a metallorganic complex laser radiation Metal Nitrogen Oxygen 33

Laser-activated additive metal atom Metal Nitrogen Oxygen 34

LDS Technical Summary

Micro-etched, laser Bild mit strukturierter activated surface Oberfläche und unstrukturierter Oberfläche Cu Smooth, unactivated surface Chemical and mechanical “anchoring“ of Copper plating

Rapid Product Development

3D-Antenna by LDS Source: Harting Mitronics

Attach components Source: Harting Mitronics

Prototyping & Development Source: ProtoLabs

Prototyping & Development

Connectivity

SelectConnect Metalization Electroless Copper Electroless Nickel Immersion Gold [Electroless Gold] Copper 100 - 250 micro-inches (5 -6 µm) Nickel 50 - 100 micro-inches (2 - 3 µm) Gold Immersion, ~ 8 micro-inches (0.2 µm) Electrolytic gold option

The Future Holds….

The Future Holds…. Wider Frequency Ranges Multiple Antennas per Device (MIMO) More Bandwidth (LTE) High Frequencies (smaller antenna) Adaptive, beam forming antennas

The Future Holds….

The Future Holds….

The Future Holds….

RFID RFID-Transponder Source: Harting Mitronics AG

I like LDS…

Now what?

ITAR Registered ISO 9001: 2008

Supply Chain Partners LDS Technology and Rapid prototype parts Lasers Aerospace, medical, defense and large volume molding High quality and low/mid volume, fast turn molding Electronic assembly 3D circuit design Antenna design

Our Customers

LDS and 3D-MID Services SelectConnect Technologies Division of Arlington Plating Company Palatine, Illinois Suburban Chicago Jim Liddle 847.359.1490 jliddle@selectconnecttech.com www.selectconnecttech.com

Recommend

More recommend