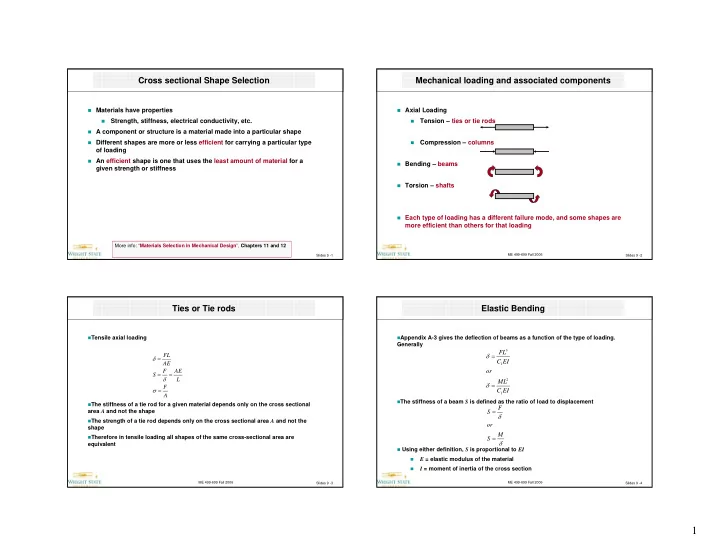

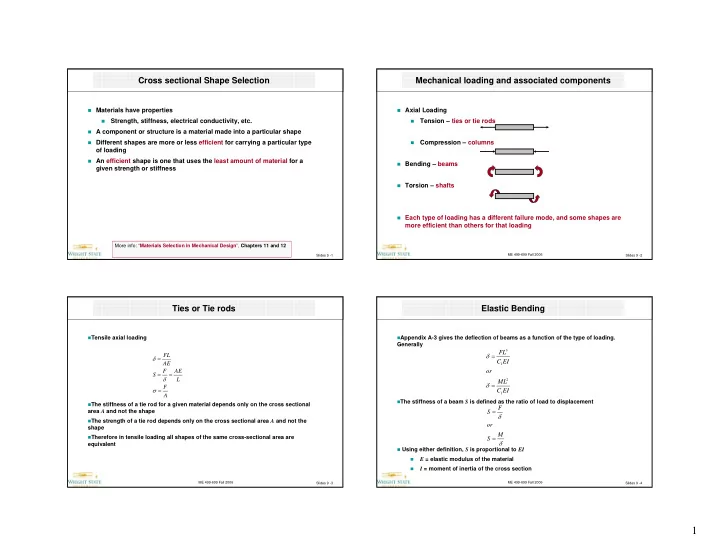

Cross sectional Shape Selection Mechanical loading and associated components � Materials have properties � Axial Loading � Strength, stiffness, electrical conductivity, etc. � Tension – ties or tie rods � A component or structure is a material made into a particular shape � Different shapes are more or less efficient for carrying a particular type Compression – columns � of loading � An efficient shape is one that uses the least amount of material for a � Bending – beams given strength or stiffness � Torsion – shafts � Each type of loading has a different failure mode, and some shapes are more efficient than others for that loading More info: “ Materials Selection in Mechanical Design ”, Chapters 11 and 12 ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 9 -1 Slides 9 -2 Ties or Tie rods Elastic Bending � Tensile axial loading � Appendix A-3 gives the deflection of beams as a function of the type of loading. Generally 3 FL δ = FL δ = C EI AE 1 F AE or = = S δ L 2 ML δ = F σ = C EI 1 A � The stiffness of a beam S is defined as the ratio of load to displacement � The stiffness of a tie rod for a given material depends only on the cross sectional F = area A and not the shape S δ � The strength of a tie rod depends only on the cross sectional area A and not the or shape M = � Therefore in tensile loading all shapes of the same cross-sectional area are S δ equivalent � Using either definition, S is proportional to EI � E = elastic modulus of the material I = moment of inertia of the cross section � ME 499-699 Fall 2006 Slides 9 -3 ME 499-699 Fall 2006 Slides 9 -4 1

Elastic Bending Elastic Bending � I = Moment of inertia of the cross section � Derive shape factor for elastic bending of ∫ = � Square cross-section of side a 2 I y dA − Cross section � Hollow tube of radius r and thickness t where r >> t � For a square cross section � Table 11.2 gives the section properties of different shapes π S EI 4 � For a circular cross section φ = = = = e sq sq 1 . 05 B S EI 12 O O = π 2 A r π 4 2 r A = = I O π � For a hollow tube 4 4 S EI I r φ = = = 4 π = � If S = C 2 EI is the stiffness for another shape with the same cross sectional e B 2 S EI A t area made of the same material and subject to the same loading, then the O O shape factor for elastic bending is defined as S C EI I φ = = = π e 1 4 B 2 S C EI A O 1 O ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 9 -5 Slides 9 -6 Elastic Bending - Square cross-section beam Elastic Bending – Tubular beam � For a square cross-section of side a � For a tubular beam with radius r and wall thickness t where r >> t = = π 2 A a A 2 rt = π 4 2 3 a A I r t = = tube I sq 12 12 � Compare with a circle with the same area A � Shape factor during elastic bending of a tubular beam relative to a circular cross- section of the same area is: 4 π = I I π 3 S I I r t r sq O φ = = = = π = 12 e tube tube ( tube ) 4 ( ) π B 2 π 2 S I A / 4 2 rt t O O � Shape factor during elastic bending of a square cross-section relative to a circular cross section of the same area is: � Therefore, a thin walled tubular beam with r = 10t is 10 times as stiff as a circular ( ) cross-section beam of the same area π S I 2 A / 12 4 φ = = = = = e sq sq ( ) 1 . 05 π B 2 S I A / 4 12 O O � Therefore, a square cross-section is about 5% stiffer than a circular cross-section ME 499-699 Fall 2006 Slides 9 -7 ME 499-699 Fall 2006 Slides 9 -8 2

Elastic Bending Elastic Bending 0.01 � The shape factor φ B e is dimensionless, i.e. it is a pure number that � EduPack Level 3 includes most of the commercially characterizes the cross-sectional shape relative to a circular cross- Hot Fin. Steel (Y.S. 355MPa) Rect.Hollow -(150x150x5.0) 1e-3 available structural shapes section Second moment of area (major), I_max (m^4) made from different Pultruded GFRP Vinyl Ester I-section-(102x51x2.1) 1e-4 materials. Phi=100 I sections with � Using a plot of the moment 1e-5 φ B e = 10 I φ = π of inertia versus section e 4 B 2 A area one can compare 1e-6 different structural shapes Hollow tubes with Hot Rolled Steel (Y.S. 355MPa) Universal Beam-(203x133x25) 1e-7 φ B e = 10 1e-8 Extruded Aluminum circular hollow (Y.S. 255MPa)-(32x2.6) 1e-9 Increasing size with constant shape 1e-10 1e-11 1e-4 1e-3 0.01 0.1 Section area, A (m^2) ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 9 -9 Slides 9 -10 Failure in Bending Failure in Bending � Failure in bending can be defined as the initiation of plastic deformation � For a circular cross-section in the beam. π � The stress on the top and bottom surfaces of a symmetric beam is given = 4 I r by 4 Mc M σ = = = c r I Z where Therefore I = π Z 3 3 / 2 r A = = c Z O π 4 4 � Where c is the distance of the top or bottom surface from the neutral surface � At yield, σ = σ f = yield stress ME 499-699 Fall 2006 Slides 9 -11 ME 499-699 Fall 2006 Slides 9 -12 3

Failure in Bending Failure in Bending – Square cross section beam � Define the shape factor for failure in bending as � For a square of side a = 2 A a Z φ = f 4 a B = Z I O 12 � Derive ( ) 3 3 / 2 I a A = = = Z ( ) sq � For a square of side a a / 2 6 6 � The shape factor for a square cross section is π Z 2 φ = = = sq f 1 . 18 B Z 3 ( ) ( ) O π Z 3 / 2 A / 6 2 φ = = = = f sq ( ) 1 . 18 ( ) B π 3 / 2 Z A / 4 3 � For a hollow cylinder of radius r and wall thickness t , where r >> t O � The square cross section almost 20% stronger than a circular cross- Z r φ = = f 8 section B Z t O ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 9 -13 Slides 9 -14 Failure in Bending – Tubular beam Elastic Torsion T θ = � For a tubular beam with radius r and wall thickness t where r >> t � During elastic torsion, the angle of twist per unit length is JG = π A 2 rt = π � Where T is the torque, J is the polar moment of inertia, and G is the shear modulus of 3 I r t the material. I = = π = π 2 Z r t 2 A r tube r π 2 A = = 4 J r � The shape factor for a tubular beam is π 2 2 π π 2 2 Z r t r t r φ = = = π = ( ) f tube � The stiffness of a solid circular shaft in torsion S T is defined as the ratio of load to angle 4 8 ( ) ( ) ( ) B π π 3 / 2 3 / 2 Z t A / 4 2 rt of twist per unit length O T = θ = S J G T O O � The tubular beam with r = 10t has a shape factor of 8.9, i.e., the tubular beam is � The shape factor for a different cross section is defined as almost 9 times as strong as a circular cross-section beam S GJ J φ = = = e T ( ) T π 2 S GJ A / 2 T O O ME 499-699 Fall 2006 Slides 9 -15 ME 499-699 Fall 2006 Slides 9 -16 4

Elastic Torsion Failure by plastic deformation during Torsion � The shear stress at the surface of a cylindrical shaft subject to a torque T is � For a hollow shaft with radius r and wall thickness t where r >> t Tr T T τ = = = ( ) = π J J / r Q A 2 rt O O O where ≈ π 3 J 2 r t π = 4 J r O 2 � Shape factor for elastic torsion is and π 3 / 2 π π A 3 2 3 2 r t 4 r t r = = 3 φ = = = Q r e ( ) O π π π 2 T 2 2 2 2 2 A / 2 4 r t t � Failure occurs when the stress reaches the shear yield stress, or one-half of the � Therefore, a thin walled shaft with r = 10t is 10 times as stiff as a circular cross- tensile yield stress σ section shaft of the same area T τ = 2 = f f Q O � The shape factor for a shaft of a different cross-section can be defined as Q Q φ = = π f 2 T 3 / 2 Q A O ME 499-699 Fall 2006 ME 499-699 Fall 2006 Slides 9 -17 Slides 9 -18 Shape factor for failure in Torsion of a Hollow Shaft Homework Assignment � For a hollow shaft with radius r and wall thickness t where r >> t � Show that the shape factor of elastic buckling is the same as that for elastic bending = π A 2 rt ≈ π 3 J 2 r t J = = π 2 Q 2 r t r � Shape factor is π 2 Q 2 r t 2 r φ = π = π = f 2 2 ( ) T π 3 / 2 3 / 2 A 2 rt t � Therefore, a thin walled shaft with r = 10t is 4.5 times as strong as a circular cross- section shaft of the same area ME 499-699 Fall 2006 Slides 9 -19 ME 499-699 Fall 2006 Slides 9 -20 5

Recommend

More recommend