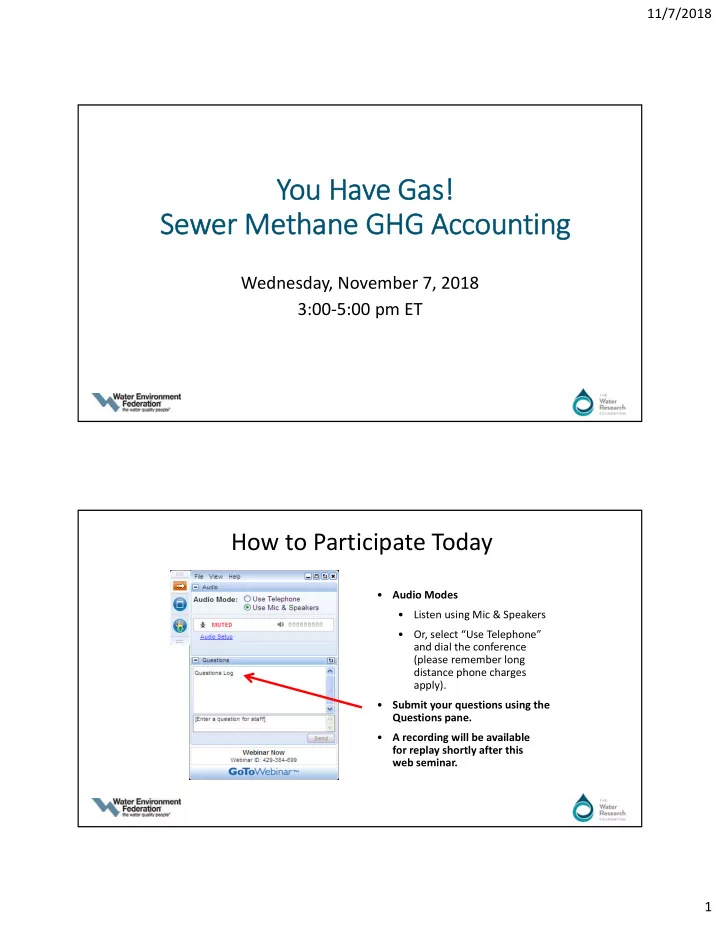

11/7/2018 You Have Gas! Sewer Methane GHG Accounting Wednesday, November 7, 2018 3:00‐5:00 pm ET How to Participate Today • Audio Modes • Listen using Mic & Speakers • Or, select “Use Telephone” and dial the conference (please remember long distance phone charges apply). • Submit your questions using the Questions pane. • A recording will be available for replay shortly after this web seminar. 1

11/7/2018 Today’s Moderator Christine Radke, PMP The Water Research Foundation Speakers John Willis, Ph.D., Keshab Sharma, Ph.D. Asbjorn Haaning‐Nielsen, Wendy Barrott, Ph.D, PE PE, BCEE University of Ph.D. Great Lakes Water Brown & Caldwell Queensland (Australia) Aalborg University (Denmark) Authority (Michigan) 2

11/7/2018 WEF Webinar November 7, 2018 New GHG Methodology to Estimate/ John Willis, Ph.D., P.E., BC Keshab Sharma, Ph.D., UQ-AWMC Quantify Sewer Methane Asbjørn Haaning Nielsen, Ph.D., Aalborg U. Wendy Barrott, Ph.D., P.E., GLWA With contributions by: B. Brower, C. Peot, S. Murthy (DC Water); P. Regmi (BC); W. Graf (WRF); and Z. Yuan (UQ-AWMC) Presentation Overview • Introduction, GHG Context, and Sewer‐CH 4 Concepts Willis • Sewer‐CH 4 Methodology Details Willis • Method Development Sharma • Gravity‐Sewer‐Method Verification Willis • Forcemain‐Method Verification Sharma • Assessment of Method and Related Research Haaning Nielsen • Utility Perspective and Use of Methodology Barrott • Conclusions Willis 6 3

11/7/2018 Introduction, GHG Context, and Sewer-CH 4 Concepts John Willis, Ph.D., P.E., BCEE, Brown and Caldwell Conflict exists between GHG Protocols and Scientific Research on Sewer‐CH 4 Our research suggests IPCC and other that over half of the GHG protocols US Centralized assume there is VS VS. Wastewater No CH 4 from Industry’s Scope‐1 sewers in the GHG emissions are developed world from sewer CH 4 8 4

11/7/2018 Our Research Suggests Sewer CH 4 is over 50% of Centralized Scope‐1 GHG Our Research Suggests Sewer CH 4 is over 50% of Centralized Scope‐1 GHG How can this be reconciled with IPCC’s determination that sewer CH 4 can be ignored in the developed world??? 5

11/7/2018 It is Due to Sewer‐CH 4 ’s Relative Insignificance on a National Scale The USA’s total GHG emissions are nominally 7.0 B-MT CO 2 e/yr It is Due to Sewer‐CH 4 ’s Relative Insignificance on a National Scale • The USA’s total GHG emissions are 7.0 B-MT CO 2 e/yr • All WW is 41 M-MT CO 2 e/yr (0.59%) • Centralized WW is 24 M-MT CO 2 e/yr (0.34%) Sewer-CH 4 is • 1 M-MT CO 2 e/yr (0.015%) 6

11/7/2018 Inconsistency between Protocols and Research IPCC and other GHG methodologies Our research suggest that sewer CH 4 assume ZER ZERO CH CH 4 fr from om se sewers rs VS. is ove over hal half of the US US Wastew Wastewate ater r in the developed world… Industry’s Scope Industry ’s Scope-1 GHG 1 GHG emissions… • The method discussed is relatively straightforward and yet data intensive and dependent on fairly robust collection‐system hydraulic models. • We are looking for interested to utilities to either: 1) Employ the method , OR 2) Have us Employ the Method (you get a system‐specific emissions equation as f(flow, temperature) ; that can be used to estimate daily‐to‐annual GHG AND Share your results so we can develop a further simplified methodology , likely as f(size, temperature, %gravity/surcharged) that “anyone” can use 13 Sewer CH 4 Production • Slime (biofilm) layers provide long residence time to support methanogens in deeper layers • Sulfide reducers and hydrolyzers Bulk Liquid at are more prominent in outer layers Average Flowrates • Some flow/velocity is needed to Slime Area/”Capacity” is infuse carbon and sulfate into “Set” at Average Flowrates biofilm • Sediments do not normally Sediments contribute to CH 4 14 7

11/7/2018 Overall CH 4 Mass Balance 15 Sewer-CH 4 Methodology John Willis, Ph.D., P.E., BCEE, Brown and Caldwell 8

11/7/2018 Methodology uses Two Equations • Gravity‐Sewer Model: r CH4‐GS = 0.419 x 1.06 (T‐20) x Q 0.26 x D 0.28 x S ‐0.135 r CH4 , = CH 4 emission rate in kg CH 4 /(km*day) = Temperature in O C T = Flow in m 3 /s Q D = Pipe diameter in m S = Slope in m/m • Forcemain/Surcharged‐Sewer Model: r CH4‐FM = 3.452 x D x 1.06 (T‐20) 17 Equations are used for each Segment/Partial Segments • Hydraulic model at average flow provided “shape file” (we’ve used Excel) • If the hydraulic grade is below the pipe crown at both ends: Gravit Gravity • If the hydraulic grade is above the pipe crown at both ends: Surcha Surc harged • If the hydraulic grade is above the pipe crown at one and below the crown at the other: Gravit Gravity and Surc Surcharged rged Can assume linear changes in hydraulic and crown grade 9

11/7/2018 How to Estimate Collection System Temperatures? • If you measure raw sewage temperatures, they can be used. • If not: • A correlation to commonly measured temperatures can provide a “surrogate” • Or, as a fallback, this DC Water correlation could also be used as a less‐accurate translation 19 Temperatures remapped across 2014 Effluent Data 20 10

11/7/2018 Method Development Keshab Sharma, Ph.D. The University of Queensland - Advanced Water Management Centre SeweX Model Development Schematic representation of the model: SRB processes (solid lines), FB processes (dash‐dotted lines), and MA processes (dashed lines) 11

11/7/2018 SeweX has been Widely Used over Last 10 years • Over 30 sewer catchments have been modeled with SeweX with full scale data collected to calibrate/verify approximately 30% of these 20 20 Measured Measured Model Model Dissolved Methane (mg/L) Dissolved Methane (mg/L) 15 15 10 10 5 5 0 0 11 Feb 12 Feb 13 Feb 14 Feb 15 Feb 16 Feb 18 April 19 April 20 April 21 April 22 April 23 April 2014 2014 2014 2014 2014 2014 2014 2014 2014 2014 2014 2014 Date Date Gold Coast (Australia) Measurements vs. SeweX‐Predictions for Summer (Feb. 2014) and Fall (April 2014) Empirical GS‐Model Development and Application Sewer Properties Calibrated Sewer Model Length = 1000 m (constant) Pipe Diameter = D mm Pump run time = P (min/day) Simulations to estimate methane production Average daily flow = Q (m3/s) with under each set of sewer conditions diurnal variation Temperature = T ◦ C A range of the parameters/sets of Non‐linear regression of the simulation results data to sewer conditions to be applied develop a correlation between the sewer parameters and the methane production Network Data Pipe length Pipe diameter Average daily flow Methane production in each pipe section to obtain Pump run time (hours/day) total methane production in the entire sewer Temperature network 12

11/7/2018 GS‐Model Development for Gravity Sewer (GS) GS‐Model Methodology • Diurnal variation of sewer flow was assumed. A typical flow profile was used and the same profile was employed to all the pipes irrespective of their size and flow. • Water depth and flow velocity in sewer pipes were estimated as a function of pipe size, flow and slope using Hazen‐Williams equation. • Typical domestic sewage characteristics were used. • Parameters calibrated for methane production in a sewer system in Australia were employed. • Same parameters were used for all the sewer pipes irrespective of their size, flow, flow velocity, and water depths. 13

11/7/2018 GS‐Model Validation Estimated Values for Parameters Correlation Coefficients of Estimated Parameters Effects of COD and SO 4 Concentration COD SO 4 14

11/7/2018 Simulated Wastewater Flow Profiles Comparison of Methane Production Rates for Tested Flow Profiles 15

11/7/2018 Methane Generation in Gravity Sewer Where, 𝑠 �� � = Methane production rate (kg/km‐day) 𝑅 = Average flow over a day (m 3 /s) 𝐸 = Pipe diameter (m) 𝑇 = Pipe slope (m/m) FM‐Model Development for Force Main D 16

11/7/2018 Effect of Flow on Methane Production Effect of Pipe Size on Methane Production 17

11/7/2018 FM‐Model Methodology Pipe diameters ranging from 100 mm to 1500 mm Flow varied between 1 L/s and 3000 L/s depending upon the pipe size Constant sewer flow Typical domestic sewage characteristics Parameters calibrated for methane production in a sewer system in Australia Same parameters were used for all the sewer pipes Typical Flow Profile Used • A pump station model to generate hydraulic profile • A number of different parameters considered • incoming flow rates • pump capacities • wet‐well dimensions duty levels were 36 18

11/7/2018 Comparison of Results Methane Production Rate (kg/day-km) 8 Estimated Values for Parameters + 23% 6 Predicted Rate 4 - 36% 2 0 0 2 4 6 8 Expected Rate Methane Generation in Force Main Where, 𝑠 �� � = Methane production rate (kg/km‐day) 𝑈 = Temperature( o C) 𝐸 = Pipe diameter (m) 𝑂 � = Number of pumping events per day 𝑄 � = Average pumping interval (min) 19

11/7/2018 Gravity-Sewer-Method Verification John Willis, Ph.D., P.E., BCEE Brown and Caldwell Overview of the Potomac Interceptor (PI) Test 20

11/7/2018 Determination of Extent Ventilated Sample ACR Output File/Figure 21

11/7/2018 Upstream Manhole Pressures Downstream Manhole Pressures 22

Recommend

More recommend