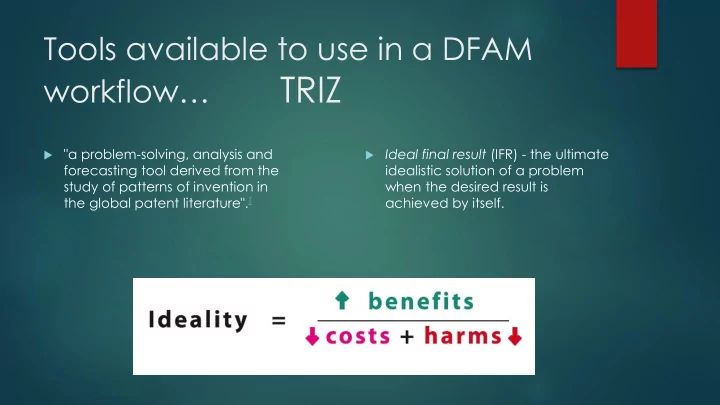

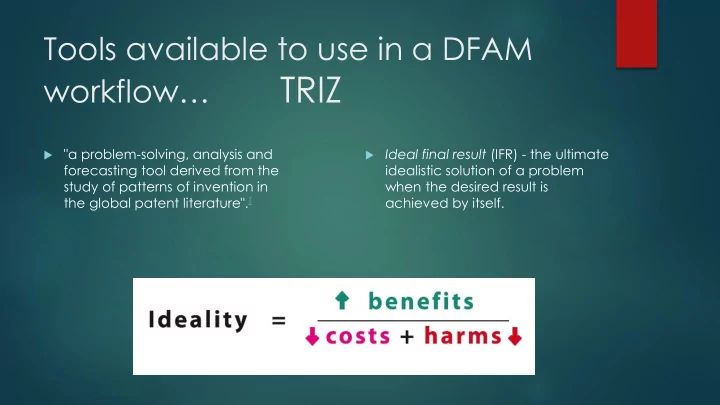

Tools available to use in a DFAM workflow… TRIZ "a problem-solving, analysis and Ideal final result (IFR) - the ultimate forecasting tool derived from the idealistic solution of a problem study of patterns of invention in when the desired result is the global patent literature". [ achieved by itself.

Develop contradictions 'A contradiction is a simple clash of solutions. Either we want Lighter weight same strength….. opposite solutions, or by introducing a new solution, i.e. an improving change to one feature in a system, another feature in our system has got worse. Engineers recognize contradictions as familiar situations, such as when we improve strength by adding more material we find that this solution often makes weight get worse.

Light weight examples….. Lighter weight, same strength…….

Convergence example (#5)

Resources……

Butler technologies..

Butler II

Customized manufacturing Ride height setup tool Camshaft tensioner pressure adapter. Coolant flange

911 printed Exhaust Manifold flanges..

Customized CNC tooling… Very difficult part to fixture. Single day lead time on printed fixture. Materials durable enough to live in a CNC environment. Friction hold, pneumatic release of part.. Alignment pin in center of fixture to orient coordinate system of CNC machine.

OraFlow™: Aids in the Treatment of Periodontal Disease Production test fixture

Oralectrics’ Solution – Zumby (medical device disguised as a toy)

Custom Quality Assurance Test Fixture • Difficult or Impossible to measure quickly and conventionally. • Rapid prototyping solution, quick, Inexpensive, accurate

PRINTED SAND MOLD CASTING Ideal for high complexity, low volume castings Ideal for replacement parts Reduces lead time significantly Avoids the need to purchase expensive tooling for small sample lots – 3D Printed molds are made with greater precision, and thus tend to hold tighter tolerances – Allows complex internal casting geometries to be created without numerous cores – Reduces variability in the molding process – Reduces the labor requirements necessary for highly-complex parts

Printed Gripper…. Bowden tube design…

Conclusion… The capabilities of additive manufacturing, of which 3D printing is part, completely turn the design process on its head from start to finish. Hayden Osborn, a tool engineer at Boeing. Broad Adoption of Additive for Tooling. GE said that 25 percent of its products will be impacted by additive by 2020. Success Through Software Existing software built for subtractive processes does not enable designers and engineers to optimize for additive processes. But new types of software coming to market, address additive processes with optimization, simulation, and build preparation for specific machine and material combinations. Materials.. Although Additive Manufacturing has been around for more than 30 years, it’s only recently that the materials suitable for use and their possible functions has really expanded. There are an almost limitless number of industries that could benefit from incorporating Additive Manufacturing into the processes, changing the face of what’s possible.

More information https://www.dropbox.com/sh/tsx5a59cdgo0spi/AACi6fDFHhaO8Pnx KtFAh0Sba?dl=0

Recommend

More recommend