What is a Radio Telescope? Instead of using optics, it focuses and - PowerPoint PPT Presentation

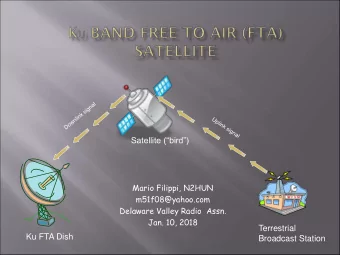

What is a Radio Telescope? Instead of using optics, it focuses and Allows us to study amplifies radio waves to generate a picture. astronomical objects We are primarily looking at 1420 Mhz. Problem Statement / Design Considerations 4.5 m

What is a Radio Telescope? Instead of using optics, it focuses and Allows us to study amplifies radio waves to generate a picture. astronomical objects We are primarily looking at 1420 Mhz.

Problem Statement / Design Considerations ● 4.5 m ≈15 ft dish ● John C. Rudy Park ● Auto Tracking ● Autolocating ● Withstand elements

Overview Physical Design Phase Construction Radio Telescope: Goal

ME Team Jessie Furey - ME Darin Gordon - ME Josh Sowa - ME Richard Hopkins - ME Marcos Rivera - ME Don Hake - Project Manager - Capstone Lead Dr. Stephen WIlkerson PhD, P .E. - ME Advisor Dr. Kala Meah PhD - EE Advisor

Major Components of Radio Telescope ME Capstone Team took charge ● and completed several major systems ● ME Finished designing and fabricating Pedestal, Elevation Frame. ● Planning and Layout for Triangle Connector and Existing Dish Overview of Radio Telescope Assembly

Pedestal (What we had) Setup of pedestal at Voith Hydro Machining of plate flanges Tube and Flanges getting ready to transport to Wolfe Tool Machine Shop

Pedestal (We broke ground!) Excavation Site at John Rudy Pedestal On Site Perimeter Fencing Completed Pedestal Layout of Template

Azimuth Sensor mounts

Elevation sensor mount

Elevation Frame (Where we started) Parts provided: ● Base plates ● Tubing ● Side plates ● Elevation rod Base plates and tubing ● Timken bearings ● APEX gearbox Design provided by previous team Side plates

Elevation Frame (What we did) Finite Element Analysis Partial View of Drawings Our final design

Elevation Frame (Current Status) Remaining work: Completed elevation frame subassembly ● Paint shims ● Organize safe lifting method ● Place on azimuth

Cover - Preliminary Design Basic requirements ● Removable by a single person without disassembling the telescope ● Light weight and water resistant ● Long lifespan Left and right pieces of cover Cover with removable panel

Triangle Connector (Where we started)

Triangle Connector (Where we're going) Final Triangle Connector Examination of Counterbalance FBD of TC & Assembly Connection Dish TC 10 degrees below horizontal

Triangle Connector (Where we're going) FEA of the worst case at 30 mph winds 0 degree Orientation). Factor of Safety of 2.5 FEA at 90 degrees orientation-Stowed. FOS of 2.5 FEA of the worst case at 30 mph winds at 60 degrees orientation. FOS of 3.3

Triangle Connector (Challenges) Planetary Gear reduction 10:1 Mock Up of Triangle Plate with Hub & Struts 24 VDC Brake Motor Template of Plate Redesign of Triangle Connector

TC Fabrication A.E.C.S Inc. ME TEAM NSC A.E.C.S Inc. ME TEAM Components fabricated to specifications

TC Component Inspection Inspection Drawings and corresponding inspection sheet for all components TC-4 Inspection Drawing

TC Weld Subassemblies Subassembly Drawing 4 Weld Subassemblies

TC Final Weld Assembly ● Final Weld Assembly ● Post Weld Inspection

TC Post Machining Bearing Plate Close Up Triangle Connector Post Machining

Existing Dish (Dry Assembly) One petal assembled. Assembling the braces and ribs of the existing dish.

Existing Dish (New Looks) Sandblasted and Painted Components Existing Components

Upper Assembly Testing/Preparation Design of Test Frame Modifications of Test Stand Moving Azimuth off the Table ● Testing the Upper Assembly Safely with additional mass Required higher quality casters and more ● maneuverable size

Sponsors

Acknowledgements Barry L Myers-York County Parks Superintendent Joshua Carney, P .E.-CEG Jim Leedy-Excavator Becton Dickinson & co-workers John Diehl-Kinsley Project Manager Tammy Klunk-Former York County Parks Director Jerry Stultz-Kinsley Superintendent Arnold Offner-Phoenix Contact Josh Dewees-Parks Maintenance Keith Murr-TE Connectivity Mike Culp-Voith Hydro Denise Culp-Purchaser Scott Amereihn-Shop Foreman Wolfe Tool Co Dan Shook-A.E.C.S. Steve Catlett-President of SSE

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.