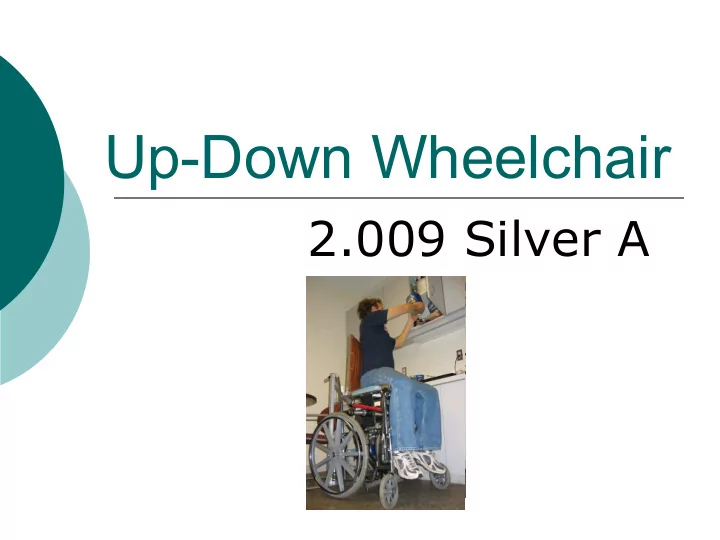

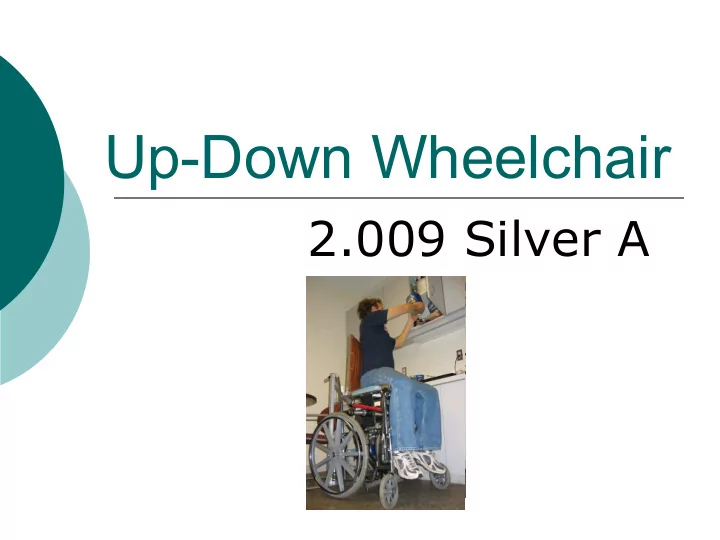

Up-Down Wheelchair 2.009 Silver A

Design Specifications Requirements Attributes Specifications Reach Lift System Seat height 9-33 ” Wheel brakes, Handles 100kg Sliding bearings without tipping Safety and stability Weight Hydraulic jack 1500N force output Meets all ASA requirements Standard mobility Modified chassis

Critical Issues and Solutions ¡ Hydraulic System l Easy to lift 24 ” l Compactness l Optimal system ¡ Stability l Smooth vertical motion l Torsional strength ¡ Cost l Manual Chair ~ $150 l Electric Lift Chair ~ $3000

Design Process ¡ Modify wheelchair structure ¡ Decouple and modify jacks ¡ Stabilize chair ¡ Integrate components Bottle Jack Guided seat

Lessons from Model ¡ Hydraulics: l Cheap, and work well l Complex to assemble; highly sensitive ¡ Stability l Slider bearings l Torsional links ¡ Ergonomics l Jack placement: handle and scissors l Seat Angle

Conclusions ¡ Technically feasible ¡ Cost effective

Thank You

POST PRESENTATION MATERIAL

Hydraulic Design Evolution ¡ Design for cheap Decoupled Auto Jack

Stability Solution Scissor jack for vertical and forward stability Sliding Bearings for lateral stability

Cost Fabrication Cost: <$300 Customer Demand: $500 ¡ Typical Wheelchair ~$200 ¡ Wheelchair Manufacturing < $150 ¡ Chiropractors and Doctors dealing with temporary ¡ Hydraulics Manufacturing injuries < $50 ¡ Libraries and stores ¡ Bearings < $50 desiring extra handicapped ¡ Assembly < $50 accessibility ¡ 80% Covered by Medicare for individual users

The Hydraulics Drive Piston Response Piston One Way Check Valves Manual operation Pressure Release Reservoir 1 Sarcopenia: As We Age Muscle Loss Occurs, Ezine Articles <http://ezinearticles.com/?Sarcopenia:-As-We-Age-Muscle-Loss-Occurs&id=297128>

Pressure Drive

Recommend

More recommend