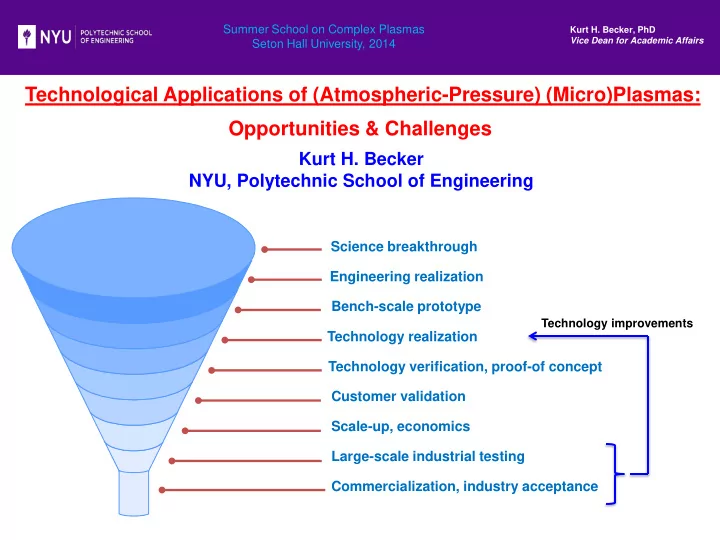

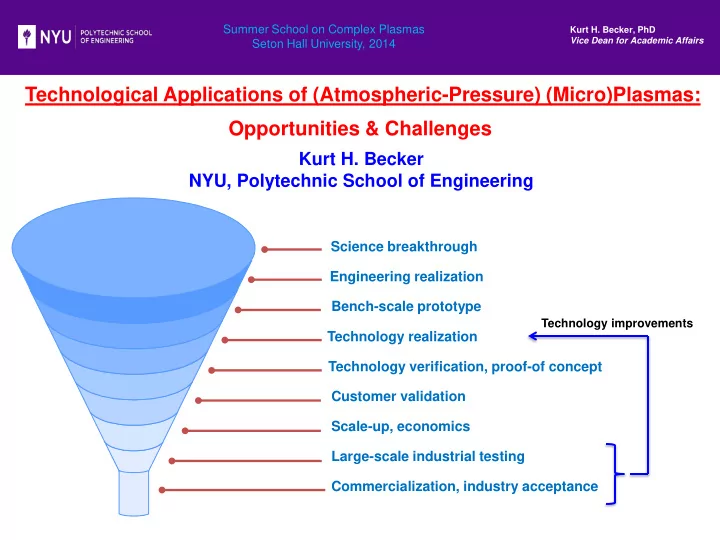

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Technological Applications of (Atmospheric-Pressure) (Micro)Plasmas: Opportunities & Challenges Kurt H. Becker NYU, Polytechnic School of Engineering Science breakthrough Engineering realization Bench-scale prototype Technology improvements Technology realization Technology verification, proof-of concept Customer validation Scale-up, economics Large-scale industrial testing Commercialization, industry acceptance

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Not covered: • Plasma Light Sources (quite mature) • Plasma Medicine (too early, regulated ) FROM: B.M. Penetrante and S.E. Schultheiss “Non-thermal Plasma Technologies for Pollution Control” Proc. NATO-ASI, Vol. 34, Plenum Press, New York (1993) “Non-thermal plasmas have an enormous potential of becoming the leading technology for the remediation of environmental pollutants in the near future” 20 Years Later: Much of the “enormous potential” remains unrealized - why ??? What are the challenges, where are the opportunities ??? TO DATE: Only two fully commercialized large-scale plasma-based technologies in the environmental field: Electrostatic Precipitators & Ozonizers

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 I. Electrostatic Precipitators (using corona discharge plasmas): Removal of particulates from gas streams • mature technology • large industrial scale • economical & efficient • reliable • little unknown science • some engineering issues

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Electrostatic Precipitators (using corona discharge plasmas) Science breakthrough Engineering realization Bench-scale prototype Technology realization Technology verification, proof-of concept Customer validation Technology improvements Scale-up, economics Large-scale industrial testing Commercialization, industry acceptance

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 II. Ozonizers (using dielectric barrier discharge, DBD, plasmas): Generation of ozone (O 3 ) for disinfection applications • mature technology • large industrial scale • fairly economical • fairly reliable • not efficient (< 20% O 3 ) • some unknown science • engineering issues

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Filamentary DBD and O 3 Generation (complex interplay between plasma chemistry & discharge physics) • low power, many weak filaments • low O 3 generation efficiency at low O 3 background concentrations • high O 3 generation efficiency at high O 3 background concentration • high power, few strong filaments • low O 3 generation efficiency at high O 3 background concentrations • high O 3 generation efficiency at low O 3 background concentration

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Ozone Generation in DBDs State of the Art: • Larger ozonizers can produce up to 100 kg of O 3 per hour • O 3 concentrations are typically 18 wt% in O 2 and 6 wt% in air • Use of O 2 requires <50 ppm HC contamination • Energy for 1 kg of O 3 is 8 kWh for O 2 and up to 20 kWh for air • Cost is about $2 per kg of O 3 Future Prospects: • Novel concepts (e.g. the IGS) can push max. O 3 concentration to >20% • Advances in power semiconductors (improved gate turn-off thyristors and insulated gate bipolar transistors which can switch 1 kA at 5 kV) will reduce size of ozonizers by eliminating the need for step-up transformers and allow use of more efficient excitation waveforms • Use of homogeneous self-sustained volume discharges may lead to more favorable plasma conditions for O 3 generation

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Ozonizers (using dielectric barrier discharge, DBD, plasmas): Science breakthrough Engineering realization Bench-scale prototype Technology realization Technology improvements Technology verification, proof-of concept Customer validation Scale-up, economics Large-scale industrial testing Commercialization, industry acceptance

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Application of Low-T Plasmas in ‘High Potential’ Area: Removal of VOCs, SO x , and NO x from Gaseous Streams Low-T plasmas have been used in bench-scale applications to: • convert VOCs in gaseous waste streams • convert SO x and NO x in gaseous waste streams • use in high-flow and low-volume applications • convert contaminants in Diesel exhaust • prepare feed gas for fuel cell Possible show-stoppers preventing industrial-scale applications : • by-product formation (characterization, control) • carbon closure (accounting for fate of all C atoms) • competing technologies (advanced oxidation techniques, catalysts, …) • energy efficiency • economics (cost of manufacture, cost of operation, …)

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Some Low-T Plasma Concepts Capillary Plasma Electrode (CPE) Concept metal dielectric ( pulsed ) dc, ac, or rf voltage dielectric metal Capillary Plasma Electrode (CPE) Realizations Solid Pin Electrodes Cylindrical Electrodes Hollow Pin Electrodes (Cross Flow) (Longitudinal Flow) (Flow-Through)

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Experimental Setup Off-Line Analysis Carbon Trap Gas Preparation Plasma Reactor Solvent Extraction GC-MS influent effluent VOCs in dry air I-V, Power On-Line Analysis 50 – 1500 ppm(v) Measurement FTIR Absorption GC-FID GC-MS (gas phase) Plasma Reactor (a) Off-line Carbon Trap Analysis GC CS 2 VOCs Vapor [VOCs] Solvent F Extraction Mass Spectrometer Flowmeter 1 Exhaust Mixtures Impinger (b) On-line Analysis FT-IR /UV/Vis Oscilloscope [ VOCs, NO x , CO x , and O 3 ] Compressed Air F Dilution Gas FID Flowmeter 2 AC GC [VOCs] Mass Spectrometer ` PC LabView Seeded Gas Preparation System Chemicals Analysis System Plasma Treatment System

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Effluent Concentration, ppm 800 100 Removal Efficiency, % Two Examples 640 80 480 60 Removal of n-Heptane in an Annular Plasma Reactor 320 40 (residence time: 0.6 s; initial 160 20 concentration: 700 ppm) 0 0 0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 Specific Energy, J/cm 3 400 100 Effluent Concentration, ppm Removal Efficiency, % 80 300 60 200 Removal of Toluene in an Annular 40 Plasma Reactor 100 20 (residence time: 0.6 s; initial concentration: 490 ppm) 0 0 0.5 1.0 1.5 2.0 2.5 0.0 3.0 3.5 4.0 Specific Energy, J/cm 3

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Initial contaminant concentration: 200 - 1200 ppm(v) Benzene Destruction flow rate: 2 - 8 l/min residence for maximum destruction efficiency 100 90 Destruction Efficiency (%) 80 In many cases conditions can 70 be found that will achieve 60 essentially 100% destruction. A-CPE Reactor 50 CF-CPE Reactor In some cases, however, NOT 40 (toluene !); back-reactions will 30 limit the maximum achievable 20 destruction efficiency. 10 0 0 2 4 6 8 10 3 ) Energy Density (J/cm We also developed a simple kinetic model for the species destruction and simulated the chemical conversion and did some by-product characterization.

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 SUMMARY: Low-T plasmas can be used effectively for the treatment of gaseous waste streams containing VOCs in a bench-scale R&D environment Low-T plasmas for Environmental Applications: • High Percentage of VOC Destruction in Low-Flow Applications • Reasonable Destruction Efficiency in High-Flow Applications • Extensive Characterization of By-Products • High Level of Carbon Closure But: Challenges Remain Scale-up to high gas flow is non-trivial Cost and energy efficiency (vs. competing technologies) Materials for long-term, maintenance-free operation Control of by-product formation Poorly understood plasma chemistry Coupling of discharge physics to plasma chemistry Large-scale industrial utilization is still elusive; the technology readiness level is “stuck” at the “proof-of-concept” stage !

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Removal of VOCs, SO x , and NO x from Gaseous Streams Science breakthrough Engineering realization Bench-scale prototype Technology realization Stuck ! Technology verification, proof-of concept Customer validation Scale-up, economics Large-scale industrial testing Commercialization, industry acceptance

Summer School on Complex Plasmas Kurt H. Becker, PhD Vice Dean for Academic Affairs Seton Hall University, 2014 Low-T Plasmas for Fuel Cell Systems Idea: Use low-T plasma to generate hydrocarbon feed gas for cell 2 m Solid Oxide Fuel Cell Chemistry 300 kW Fuel Cell

Recommend

More recommend