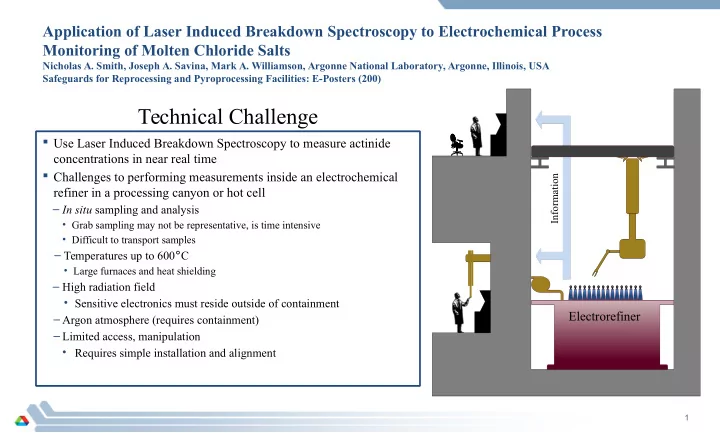

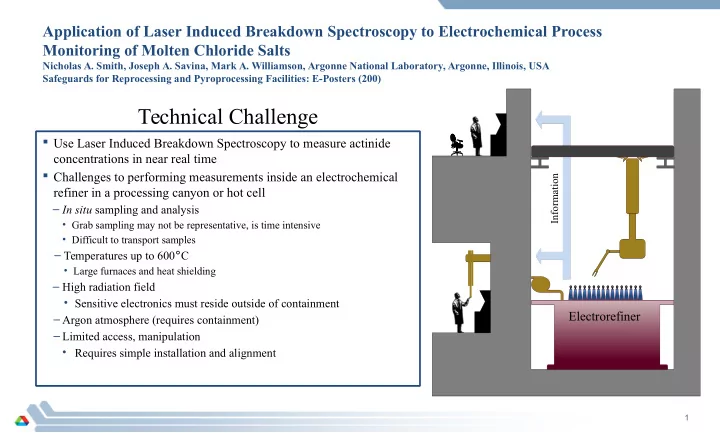

Application of Laser Induced Breakdown Spectroscopy to Electrochemical Process Monitoring of Molten Chloride Salts Nicholas A. Smith, Joseph A. Savina, Mark A. Williamson, Argonne National Laboratory, Argonne, Illinois, USA Safeguards for Reprocessing and Pyroprocessing Facilities: E-Posters (200) Technical Challenge Use Laser Induced Breakdown Spectroscopy to measure actinide concentrations in near real time Challenges to performing measurements inside an electrochemical Information refiner in a processing canyon or hot cell – In situ sampling and analysis • Grab sampling may not be representative, is time intensive • Difficult to transport samples – Temperatures up to 600 ° C • Large furnaces and heat shielding – High radiation field • Sensitive electronics must reside outside of containment Electrorefiner – Argon atmosphere (requires containment) – Limited access, manipulation • Requires simple installation and alignment 1

Application of Laser Induced Breakdown Spectroscopy to Electrochemical Process Monitoring of Molten Chloride Salts Nicholas A. Smith, Joseph A. Savina, Mark A. Williamson, Argonne National Laboratory, Argonne, Illinois, USA Safeguards for Reprocessing and Pyroprocessing Facilities: E-Posters (200) Argonne Approach Use Commercial Off The Shelf components where possible – Andor Shamrock 750 Spectrometer – Andor iStar iCCD camera and Digital Delay Generator – Quantel CFR 200 Nd:YAG laser Design requirements: – 500 mm standoff distance (lens to sample) – Plasma emissions collected via fiber optic – Class I laser system – Free beam path laser delivery was developed • The laser irradiance required to ignite a plasma at standoff distances requires large core fibers to avoid burn out • Large core fibers do not deliver a collimated beam which prevented focusing at long focal lengths • Required development of novel feed-through to add optical, logic and data connections to the glovebox without breaking containment Laser is delivered to the sample chamber by a series of beam tubes and mirrors. 2

Application of Laser Induced Breakdown Spectroscopy to Electrochemical Process Monitoring of Molten Chloride Salts Nicholas A. Smith, Joseph A. Savina, Mark A. Williamson, Argonne National Laboratory, Argonne, Illinois, USA Safeguards for Reprocessing and Pyroprocessing Facilities: E-Posters (200) Argonne Approach Use Commercial Off The Shelf components where possible – Andor Shamrock 750 Spectrometer – Andor iStar iCCD camera and Digital Delay Generator – Quantel CFR 200 Nd:YAG laser Design requirements: – 500 mm standoff distance (lens to sample) – Plasma emissions collected via fiber optic – Class I laser system – Free beam path laser delivery was developed • The laser irradiance required to ignite a plasma at standoff distances requires large core fibers to avoid burn out • Large core fibers do not deliver a collimated beam which prevented focusing at long focal lengths • Required development of novel feed-through to add optical, logic and data connections to the glovebox without breaking containment Laser is delivered to the sample chamber by a series of beam tubes and mirrors. 3

Application of Laser Induced Breakdown Spectroscopy to Electrochemical Process Monitoring of Molten Chloride Salts Nicholas A. Smith, Joseph A. Savina, Mark A. Williamson, Argonne National Laboratory, Argonne, Illinois, USA Safeguards for Reprocessing and Pyroprocessing Facilities: E-Posters (200) LIBS Testing Bench top tests – System assembled in a horizontal Zinc configuration Cu – Components were tested as a system Alignment and focus tests were carried out – Multiple metal standards were analyzed • A United States penny • Inconel (Ni/Cr/Fe) • E-Brite (Fe/Cr) – System easily resolved major metal constituents 4

Application of Laser Induced Breakdown Spectroscopy to Electrochemical Process Monitoring of Molten Chloride Salts Nicholas A. Smith, Joseph A. Savina, Mark A. Williamson, Argonne National Laboratory, Argonne, Illinois, USA Safeguards for Reprocessing and Pyroprocessing Facilities: E-Posters (200) LIBS Testing Glove box installation and testing – Initial tests focused on spectrometer performance – Tests of Inconel were repeated at multiple temperatures LIBS spectra of Inconel Crucible at 25 ° C (bottom) and 450 ° C (top), corrected for on-CCD Initial tests of Pu, U, Np trichlorides accumulations. Both graphs are displayed on the same scale, though the intensity scale was shifted for clarity. in LiCl/KCl were inconclusive – The high laser power bored holes through the frozen salt – Molten salt tests required low repetition rates to minimize splashing – Optical transparency of salts requires positioning of focal point at surface • Subsurface plasma severely reduces Salt Tests: Left – Spectrum of frozen PuCl 3 /LiCl/KCl salt cake (inset) showing large lines signal attributed to Li and K. Right – Variation of spectral intensity for surface (blue) vs. subsurface (red) plasma formation. 5

Application of Laser Induced Breakdown Spectroscopy to Electrochemical Process Monitoring of Molten Chloride Salts Nicholas A. Smith, Joseph A. Savina, Mark A. Williamson, Argonne National Laboratory, Argonne, Illinois, USA Safeguards for Reprocessing and Pyroprocessing Facilities: E-Posters (200) Conclusions Plant Scale Concepts Delivery of laser beam can be The glovebox scale LIBS system successfully fulfilled the accomplished using commercially design parameters available goniometer system – Plasma was ignited at standoff distances – Systems are made for robotic – The emissions were collected and transmitted via fiber optics automation systems and industrial – The system was certified as a Class I laser applications The system was able to measure the LIBS emissions from an – Laser, detector and spectrometers are Inconel sample available in multiple configurations – LIBS emissions were collected and analyzed depending on the application – Spectral resolution is comparable to telescopic systems The sample chamber design must be The system provides the proof of concept to move forward finalized and miniaturized with an engineering scale design – Available space on the electrorefiner is Additional studies are in progress limited – Collection of actinide LIBS spectra for quantitative measurements – Final design, regardless of laser delivery • Spectral lines/responses, limits of detection, potential interferences – Continued development of the hardware for incorporation method, must be fully self-aligning 6

Recommend

More recommend