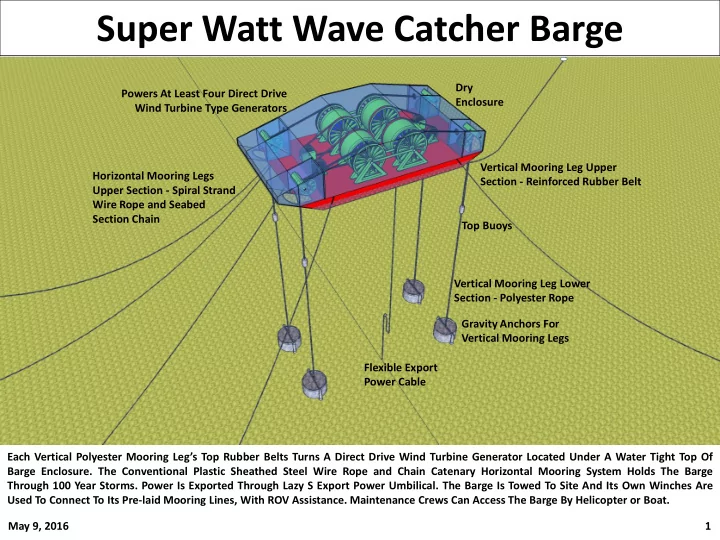

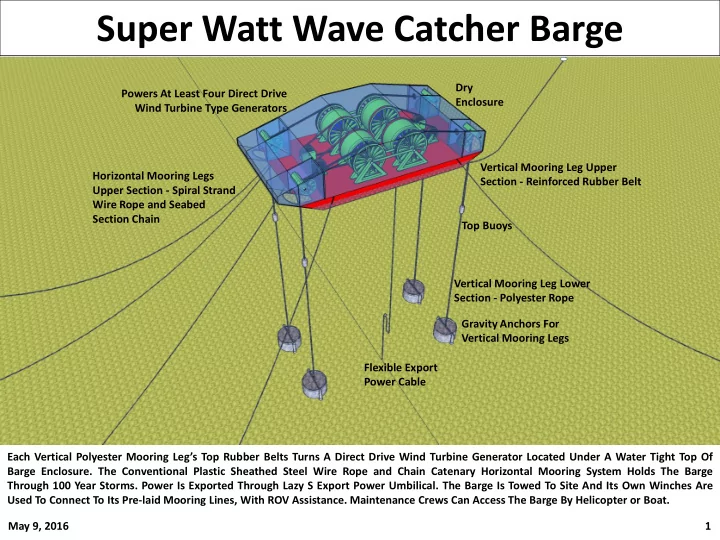

Super Watt Wave Catcher Barge Dry Powers At Least Four Direct Drive Enclosure Wind Turbine Type Generators Vertical Mooring Leg Upper Horizontal Mooring Legs Section - Reinforced Rubber Belt Upper Section - Spiral Strand Wire Rope and Seabed Section Chain Top Buoys Vertical Mooring Leg Lower Section - Polyester Rope Gravity Anchors For Vertical Mooring Legs Flexible Export Power Cable Each Vertical Polyester Mooring Leg’s Top Rubber Belts Turns A Direct Drive Wind Turbine Generator Located Under A Water Tight Top Of Barge Enclosure. The Conventional Plastic Sheathed Steel Wire Rope and Chain Catenary Horizontal Mooring System Holds The Barge Through 100 Year Storms. Power Is Exported Through Lazy S Export Power Umbilical. The Barge Is Towed To Site And Its Own Winches Are Used To Connect To Its Pre-laid Mooring Lines, With ROV Assistance. Maintenance Crews Can Access The Barge By Helicopter or Boat. May 9, 2016 1

The Stevens Institute 1/50 th Scale Model Test of the SWWCB Recorded a 650 Metric Tonnes Change In Mooring Line Load For Load Case M5s 40 (Hs=5.58m/ Tp=12 sec) May 9, 2016 2

Super Watt Wave Catcher Barge Full Scale Dimensions This presentation documents the basis of costs for the Super Watt Wave Catcher Barge for an offshore Oregon or Washington type installation site in about 100 meters of water. The costs include recent design updates, a design for most components, vertical and horizontal mooring system cost quotes, 20% contingency, etc. and are based on the economies of scale and the efficiency of a large power farm installation. The resulting CAPEX and OPEX are significantly less than land based wind power. With an expected capacity factor of about 60%, Super Watt Wave Catcher Barges should be the lowest LCOE power plant option near significant wave locations. Super Watt Wave Catcher Barges can be sized for larger swell wave locations and produce even better economics. Super Watt Wave Catcher Barges can be sized for smaller swell wave locations and still produce better economics than land based wind power. Water Depth 100 Meters Off the West Coast of the USA Power Generation Vertical Mooring System 4 - 80 meter Long 230 mm OD Polyester Mooring Rope Vertical Mooring Legs With Connectors 4 - 1.5m OD x 3 m Long Top Floats (One Supports Each Vertical Mooring Leg) 4 - .5 m wide x .1 mm thick 94m Long Reinforced Rubber Belts (Each Belt is Assumed To Be Reinforced with 7 - 24mm OD Wire Rope) 4 - 8m x 8m x 5m High Gravity Weight Boxes With 1000MT of Iron Ore In Each Box 4 - 65mm OD 984m long Jacketed Spiral Strand Wire Rope Horizontal Mooring Legs With A MBL = Storm Survival Horizontal Mooring System 4042kN 4 - 65mm OD 1022m long Jacketed Spiral Strand Wire Rope Horizontal Mooring Legs With A MBL = 4042kN 6 - 250 m long 64 mm R3 Studless Chain Lengths 6 - 6m OD x 10 m Long Suction Pile Anchors Super Watt Wave Catcher Barge Hull and Enclosure Structural Weight 2286 Metric Tonnes Weight of One Vertical Mooring System Gravty Anchor 850 Metric Tonnes Mechanical Equipment Weight 1575 Metric Tonnes As Broken Down Below: 4 - 6 Megawatt Direct Drive Generator at 150 MT Each 4 - Articulated Pulleys And Box Girder Supports at 34.19 MT Each 12- Triangular Support Frames at 9.4 MT each 4 - Uni-directional Pulleys at 23 MT each 4- Flywheel & Recoil Spring at 62.2 MT Each Draft (Including the weight of four 6 Megawatt Direct Drive Wind Turbine Generators) 1.77 meters Hull Bottom Dimensions 61.5m x 37.5m x 4m deep Enclosure Dimensions 69.5 x 37.5m x 14.5 m high Hull Bottom 1/20th Model Scale Dimensions 3.075m x 1.875m x .2m deep (Bottom Area = ~5.75 m 2 ) + Hull Sides (~.615 m 2 ) x 2 Enclosure 1/20th Model Scale Dimensions 3.475m x 1.875m x .725 m high (~6.5 m 2 ) + Enclosure Sides = 2.5 m 2 ) x 2 Description Full Scale Weight (kg) Structural weight of hull & enclosure (60.78% of the over weight) 2,286,000 Equipment Weight (Breakdown below) (39.22% of the over weight) 1,575,448 4 Articulated Pulleys And Box Girder Supports (34.19 MT each) 136,760 4 Uni-directional Pulleys With Re-coil Springs (23.55MT Each) 94,200 4 Flywheels & Recoil Springs (157.6MT Each) 630,400 4 Wire Rope Reinforced Rubber Belts (.222 MT each) 888 12 Triangular Supports (9.432 MT each) 113,200 6 Megawatt Direct Drive Generator Weight (150 MT each) 600,000 Total Weight Of Barge 3,861,448 Weight of One Vertical Mooring System Gravity Anchor (850MT) 850,000 Maximum Required Holding Capacity Of One Horizontal Mooring System Anchor Under 100 Year Storm Conditions (250MT) 250,000 Note 1: These mooring leg lengths are based on a passive horizontal mooring system. These lengths can be shorter for an active horizontal mooring system whose pretension can be increased prior to significant storms. May 9, 2016 3

Conventional Steel Wire Rope and Chain Catenary Horizontal Mooring System Note 1: These mooring leg lengths are based on a passive horizontal mooring system. The lengths can be shorter for an active horizontal mooring system whose pretension is increased prior to significant storms. May 9, 2016 4

Conventional Steel Wire Rope and Chain Catenary Horizontal Mooring System (Showing Possible Departure Angles and Near Barge Plastic Sheathed Wire Rope) May 9, 2016 5

Super Watt Wave Catcher Barge (Showing Mechanical Equipment On The Barge Deck) 4 Flywheels With Internal Recoil Springs 4- Direct Drive Wind Turbine Type Generators 4 - Articulated Pulleys Reinforced Rubber Belts Top Buoys Polyester Rope May 9, 2016 6

Super Watt Wave Catcher Barge (Port Side View Showing Mechanical Equipment On The Barge Deck) 4 Flywheels With 4- Direct Drive Wind Internal Recoil Springs Turbine Type Generators 4 - Articulated Pulleys 4-Uni-directional Pulleys May 9, 2016 7

Super Watt Wave Catcher Barge (Plan View Showing Mechanical Equipment On The Barge Deck) 4-Uni-directional Pulleys 4- Direct Drive Wind Turbine Generators 4 - Flywheels 4 - Articulated Pulleys May 9, 2016 8

Super Watt Wave Catcher Barge (Showing Barge Bottom Dimensions) Bow Stern 37.5m 8 m 53.5m May 9, 2016 9

Super Watt Wave Catcher Barge (Showing Barge Stern) May 9, 2016 10

Super Watt Wave Catcher Barge (View Of Barge’s Port Side Stern) May 9, 2016 11

Super Watt Wave Catcher Barge (Showing New Barge Stern Dimensions To Increase Stern Generator Power Output To Match Bow Generator Power Output) May 9, 2016 12

Super Watt Wave Catcher Barge (Barge Stern-No Rake Needed To Resisted Horizontal Wave Forces) May 9, 2016 13

Super Watt Wave Catcher Barge (Showing Barge Bow) May 9, 2016 14

Super Watt Wave Catcher Barge (Barge Bow-Rake Needed To Resisted Horizontal Wave Forces) May 9, 2016 15

Super Watt Wave Catcher Barge (Close Up View of A Wet Room With Its Articulated Pulley) May 9, 2016 16

Super Watt Wave Catcher Barge (6 meter OD Articulated Pulley With Support Box Girder Dimensions) May 9, 2016 17

Super Watt Wave Catcher Barge (6 meter OD Articulated Pulley With Support Section) May 9, 2016 18

Super Watt Wave Catcher Barge (Showing Mechanical Equipment On The Barge Deck) 4-Uni-directional Pulleys 4 - Flywheels 4- Direct Drive Wind Turbine Generators 19 May 9, 2016

Super Watt Wave Catcher Barge (Showing Mechanical Equipment On The Barge Deck) May 9, 2016 20

Super Watt Wave Catcher Barge (Showing Mechanical Equipment On The Barge Deck) 4 – Blue Recoil Springs Inside Flywheels May 9, 2016 21

Super Watt Wave Catcher Barge (1/20 th Scale Model Mooring Line Length Scales to 60 Meters In Length Noted In Parenthesis) May 9, 2016 22

Super Watt Wave Catcher Barge’s Horizontal Mooring System Real World Suction Pile Anchors Suction Pile Extends About 1 Meter Above the Seabed After Installation Mooring Line Burial During Preloading Mooring Line Burial During Preloading Mooring Line Attachment To Suction Pile At ~ ½ Suction Pile Penetration May 9, 2016 23

Super Watt Wave Catcher Barge’s Horizontal Mooring System’s Gravity Anchors (1/20 th Scale Model Dimensions Are In Parenthesis) Each Horizontal Mooring System’s Gravity Anchor Must Provide 31.kilograms of Sliding Resistance Force On The Test Tank Bottom May 9, 2016 24

Horizontal Mooring System 6 m OD Suction Pile Anchors (Suction piles are lowered to the seabed by an MPSV’s AHC crane. The MPSV’s ROV which helps pump the pile to design penetration in the same way that suction piles are installed worldwide. When all piles and mooring lines have been installed by the MPSV, the MPSV will pretension the mooring lines and leave the mooring lines with messenger cables to surface floats.) Suction Pile Anchor Padeye 6 m OD – 15 MT Suction Pile Anchors May 9, 2016 25

Vertical Mooring System Gravity Anchors (If Vertical Mooring Loads Become Too High, The Gravity Anchors Lift Off The Seabed Limiting the Load On The Vertical Mooring Legs. The Guide Piles Return The Gravity Anchors To Their Original Location. Iron Ore Weight Requirement Is Reduced By Gravity Anchor Suction.) Gravity anchors at the bottom of each vertical mooring line prevent mooring line overload in the event mooring line clutch disengagement failure. May 9, 2016 26

Recommend

More recommend