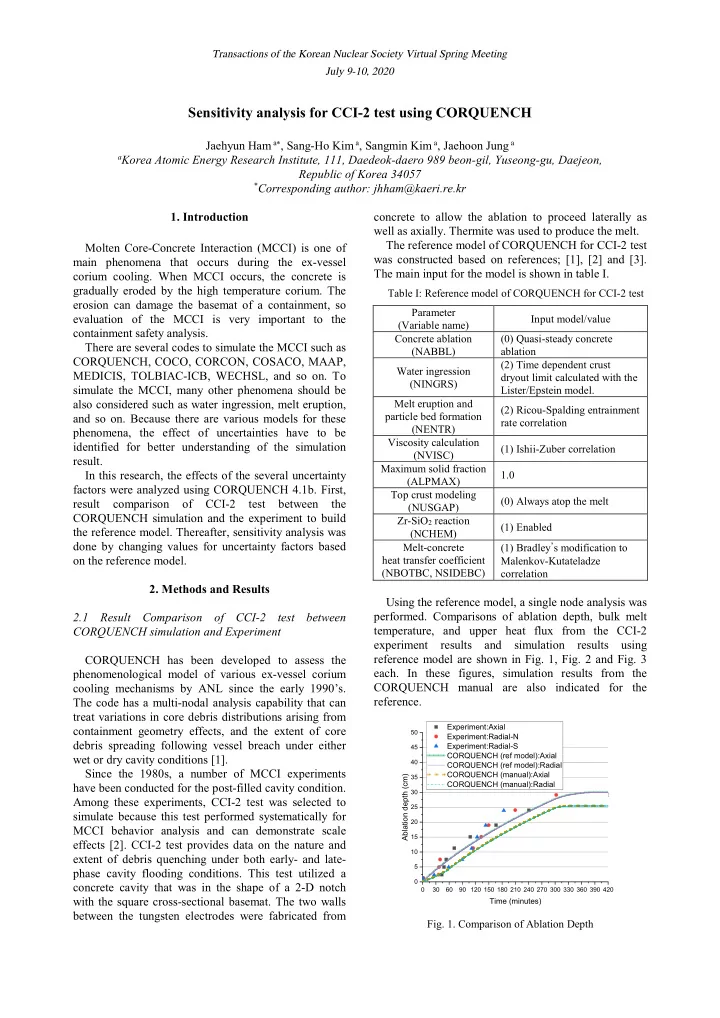

Transactions of the Korean Nuclear Society Virtual Spring Meeting July 9-10, 2020 Sensitivity analysis for CCI-2 test using CORQUENCH Jaehyun Ham a * , Sang-Ho Kim a , Sangmin Kim a , Jaehoon Jung a a Korea Atomic Energy Research Institute, 111, Daedeok-daero 989 beon-gil, Yuseong-gu, Daejeon, Republic of Korea 34057 * Corresponding author: jhham@kaeri.re.kr 1. Introduction concrete to allow the ablation to proceed laterally as well as axially. Thermite was used to produce the melt. The reference model of CORQUENCH for CCI-2 test Molten Core-Concrete Interaction (MCCI) is one of was constructed based on references; [1], [2] and [3]. main phenomena that occurs during the ex-vessel The main input for the model is shown in table I. corium cooling. When MCCI occurs, the concrete is gradually eroded by the high temperature corium. The Table I: Reference model of CORQUENCH for CCI-2 test erosion can damage the basemat of a containment, so Parameter evaluation of the MCCI is very important to the Input model/value (Variable name) containment safety analysis. Concrete ablation (0) Quasi-steady concrete There are several codes to simulate the MCCI such as (NABBL) ablation CORQUENCH, COCO, CORCON, COSACO, MAAP, (2) Time dependent crust Water ingression MEDICIS, TOLBIAC-ICB, WECHSL, and so on. To dryout limit calculated with the (NINGRS) simulate the MCCI, many other phenomena should be Lister/Epstein model. also considered such as water ingression, melt eruption, Melt eruption and (2) Ricou-Spalding entrainment particle bed formation and so on. Because there are various models for these rate correlation (NENTR) phenomena, the effect of uncertainties have to be Viscosity calculation identified for better understanding of the simulation (1) Ishii-Zuber correlation (NVISC) result. Maximum solid fraction In this research, the effects of the several uncertainty 1.0 (ALPMAX) factors were analyzed using CORQUENCH 4.1b. First, Top crust modeling (0) Always atop the melt result comparison of CCI-2 test between the (NUSGAP) CORQUENCH simulation and the experiment to build Zr-SiO 2 reaction (1) Enabled the reference model. Thereafter, sensitivity analysis was (NCHEM) done by changing values for uncertainty factors based Melt-concrete (1) Bradley ’ s modification to on the reference model. heat transfer coefficient Malenkov-Kutateladze (NBOTBC, NSIDEBC) correlation 2. Methods and Results Using the reference model, a single node analysis was performed. Comparisons of ablation depth, bulk melt 2.1 Result Comparison of CCI-2 test between temperature, and upper heat flux from the CCI-2 CORQUENCH simulation and Experiment experiment results and simulation results using reference model are shown in Fig. 1, Fig. 2 and Fig. 3 CORQUENCH has been developed to assess the each. In these figures, simulation results from the phenomenological model of various ex-vessel corium CORQUENCH manual are also indicated for the cooling mechanisms by ANL since the early 1990’s. reference. The code has a multi-nodal analysis capability that can treat variations in core debris distributions arising from Experiment:Axial containment geometry effects, and the extent of core 50 Experiment:Radial-N debris spreading following vessel breach under either Experiment:Radial-S 45 CORQUENCH (ref model):Axial wet or dry cavity conditions [1]. 40 CORQUENCH (ref model):Radial Since the 1980s, a number of MCCI experiments CORQUENCH (manual):Axial Ablation depth (cm) 35 CORQUENCH (manual):Radial have been conducted for the post-filled cavity condition. 30 Among these experiments, CCI-2 test was selected to 25 simulate because this test performed systematically for 20 MCCI behavior analysis and can demonstrate scale 15 effects [2]. CCI-2 test provides data on the nature and 10 extent of debris quenching under both early- and late- 5 phase cavity flooding conditions. This test utilized a 0 concrete cavity that was in the shape of a 2-D notch 0 30 60 90 120 150 180 210 240 270 300 330 360 390 420 with the square cross-sectional basemat. The two walls Time (minutes) between the tungsten electrodes were fabricated from Fig. 1. Comparison of Ablation Depth

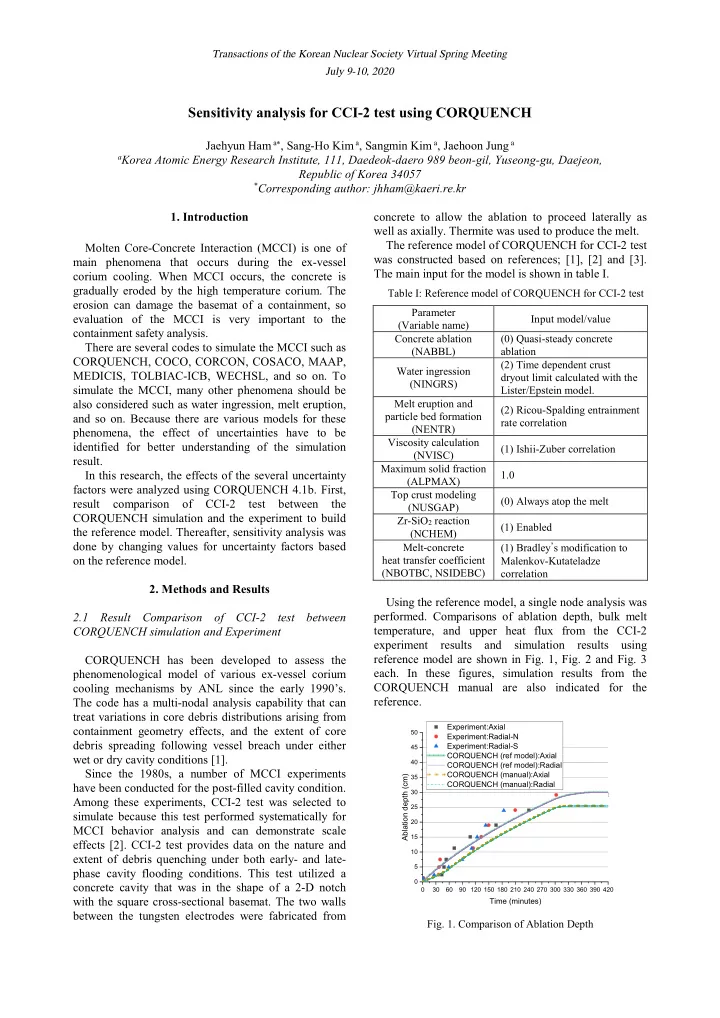

Transactions of the Korean Nuclear Society Virtual Spring Meeting July 9-10, 2020 injection (> 300 minutes) as shown in Fig. 2. The melt temperature decreases under the wet cavity condition in the simulation results, but rather the melt temperature 2400 increases in the experiment results. However, the upper Experiment 2300 CORQUENCH (ref model) heat flux increases rapidly right after the water injection 2200 CORQUENCH (manual) Bulk melt temperature (K) in both the experiment result and the simulation results 2100 as shown in Fig. 3. After the bulk cooling phase, the 2000 upper heat flux steadily decreases as the crust is formed 1900 in the experiment result, on the other hand, it maintains 1800 constantly after rapid decrease in the simulation results. 1700 Although the results show different inclination, the 1600 overall upper heat flux of the simulation results fit well 1500 the experiment result under the wet-cavity condition. 1400 Thus, it seems that the difference of the heat flux within 0 30 60 90 120 150 180 210 240 270 300 330 360 390 420 the melt is the reason why the bulk melt temperatures in Time (minutes) experiment and simulation results are different. In the Fig. 2. Comparison of Bulk Melt Temperature simulation, the whole melt is considered as a pool condition with a single temperature, on the other hand, the melt nearby the centerline in the experiment can be 3500 presumed as a locally solid based on the bulk melt Experiment temperature and upper heat flux results. Therefore, the 3000 CORQUENCH (ref model) difference in the melt temperature under the wet-cavity CORQUENCH (manual) Upper heat flux (kW/m 2 ) 2500 condition cannot be covered by the current analysis method in the CORQUENCH. In conclusion, the CCI-2 2000 test simulation result using CORQUENCH 4.1b with the 1500 reference model reasonably fit the experiment result although the simulation result doesn’t fit well the 1000 experiment result in terms of the bulk melt temperature 500 under the wet-cavity condition. 0 290 300 310 320 330 340 350 360 370 380 390 400 410 420 2.2 Sensitivity analysis Time (minutes) Based on the CCI-2 test simulation result, three Fig. 3. Comparison of Upper Heat Flux sensitivity variables were considered for concrete ablation (NABBL), concrete decomposition temperature In the simulation, axial and radial ablation depths (TDCL), and initial melt temperature (TMELTIC). were resulted as same because the same heat transfer Sensitivity analysis conditions are shown in Table II. coefficients from the Bradley’s correlation are used to Reference model inputs are marked with gray color. axial and radial interface for melt-concrete heat transfer There are three models for the concrete ablation coefficient (NBOTBC, NSIDEBC) of the reference (NABBL); Quasi-steady concrete ablation, dryout model. The simulation result using reference model fit model, and transient dryout model. Input values for the experiment result well in terms of the ablation depth, concrete decomposition temperature (TDCL) are on the other hand, the simulation results from the considered between the solidus temperature and the manual under-predicts the ablation depth as shown in liquidus temperature of a limestone/common sand Fig. 1. In terms of bulk melt temperature, simulation concrete. In this analysis, the initial melt temperature results from the manual fit the experiment result better (TMELTIC) was considered from 2050 K to 2250 K, than the simulation results using reference model until which the range is above the melt freezing point, 1975 the water injection (< 300 minutes). It is because K in the CORQUENCH 4.1b. concrete ablation models are different. In the reference model, quasi-steady concrete ablation (NABBL=0) was Table II: Sensitivity analysis condition assumed, so the evolution and failure of crust layer Parameter Input model/value between the melt and concrete are not considered. (Variable name) However, the transient dry-out model (NABBL=2) crust (0) Quasi-steady concrete ablation Concrete ablation was assumed in the manual model. Therefore, early heat (1) Dryout model (NABBL) transfer from melt to concrete is larger in the result (2) Transient dryout model using reference model than in the result from the manual. 1395 K Concrete The bulk melt temperatures in the experiment result decomposition 1430 K temperature 1465 K and the simulation results are different after water (TDCL) 1500 K

Recommend

More recommend