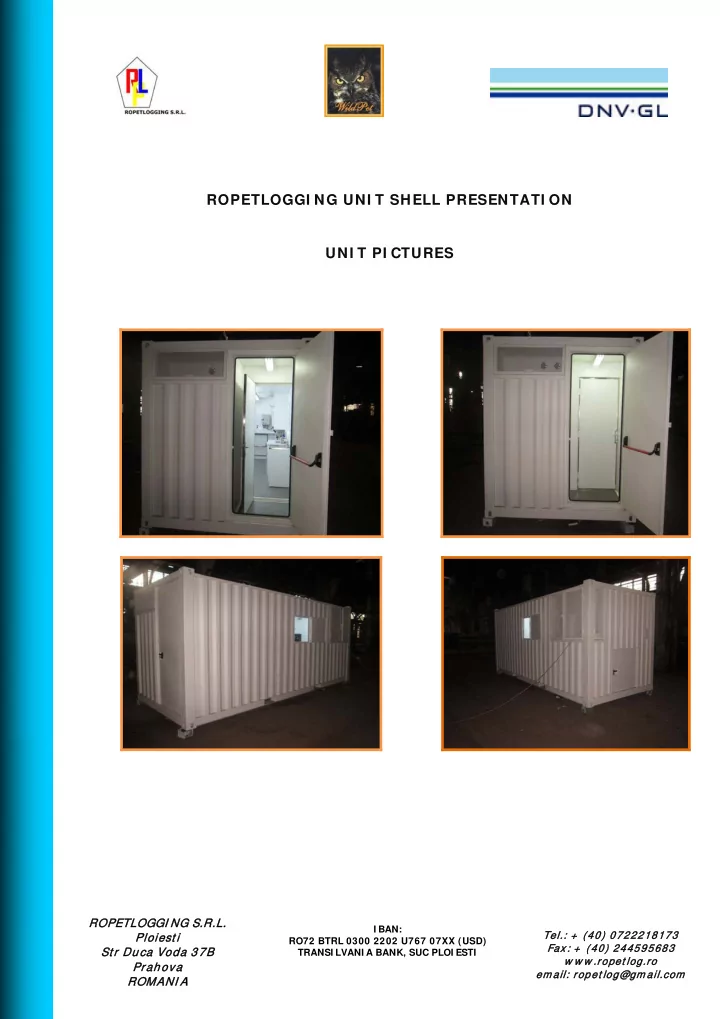

ROPETLOGGI NG UNI T SHELL PRESENTATI ON UNI T PI CTURES ROPETLOGGI GGI NG S G S.R.L. I BAN: Tel.: + (40) 40) 072 072221 22181 8173 73 Ploiest i RO72 BTRL 0300 2202 U767 07XX (USD) Fax: + (40 40) 24 2445956 595683 83 St r D Duca Vo a Voda 3 a 37B TRANSI LVANI A BANK, SUC PLOI ESTI w w w .ro ropet log.ro ro Prahova email: ro ropet log@gm ail.com ROM OMANI A

1 . GENERAL This technical specification refers at CONTAINER SERVI CE ON-SHORE 20ft according to the project, no dwg. AP4-08-2085-0 General drawing, AP4-08-2085-1-A Metal structure, belonging of Ropetlogging SRL. The actual presentation refers to the container service on-shore, but the container can be produced as a pressurized unit for off-shore operations too as per request. The service container is a Mudlogging, LWD or Wireline Unit designed to meet operating criteria for worldwide operations. The container is designed and manufactured in accordance with the technical requirements of the following standards and rules: I SO 668/ 1995; ISO 1161/ 1984; I SO 1496/ 1995; I SO 6346/ 1995 and EN 12079/ 1995. ROPETLOGGI GGI NG S G S.R.L. I BAN: Tel.: + (40) 40) 072 072221 22181 8173 73 Ploiest i RO72 BTRL 0300 2202 U767 07XX (USD) Fax: + (40 40) 24 2445956 595683 83 St r D Duca Vo a Voda 3 a 37B TRANSI LVANI A BANK, SUC PLOI ESTI w w w .ro ropet log.ro ro Prahova email: ro ropet log@gm ail.com ROM OMANI A

2 . MAI N CHARACTERI STI CS: The container is type I SO 2 0 , with dimensions and tolerances, according ISO 668/ 95. The means of conveyance may be with truck, on trayler, on railway and sea shipping. Type: CONTAI NER SERVI CE ON-SHORE 20ft I SO Designation: 1CC Model: ISO 20ft Maxim um gross m ass ( R ) : 10000 kg 22046 lbs Maxim um payload ( P ) : 5050 kg 11133 lbs Tare ( T ) : 4950 kg 10913 lbs Allow able stacking w eight: 192000 kg 423288 lbs Capacity: 30 mc External dim ensions: Length: 6058 + 0/ -6 mm Width: 2438 + 0/ -5 mm Height: 2591 + 0/ -5 mm I nternal dim ensions after m ontage insulation: Length: 5827 + 0/ -6 mm Width: 2212 + 0/ -5 mm Height: 2285 + 0/ -5 mm Dim ensions of forklift pockets: Width: 360 mm Height: 116 mm Center distance: 2000 mm Construction m aterials: - Frame: S355J2+ AR - Floor (Base structures): S355J2+ AR - Walls: S235JR - Roof: S235JR (see dwg. AP4-08-2085.6) I nternal and external coatings: - I nternal: primer - External: primer + epoxy top coat 3 . MATERI ALS The container con withstand temperatures whose extremes are between -20 0 C ÷ 50 0 C, without effect on strength of basic structure, welding and weatherproofness. The container is equipped with eight corner fittings manufactured by casting of weld able steel grade, and realize according to ISO 1161-84. The chemical analysis and mechanical characteristics of corner fittings are following: - Chemical analysis : -C: 0,11- 0,20 % , Mn: 1,10...1,50 % , Si: 0,20 - 0,60 % , P: max.0,03 % , S: max.0,03 % . - Mechanical characteristics : - Tensile strength , Rm : min. 450 N/ mm² - Yield point , Rp 0,2 : min. 240 N/ mm² - Breaking elongation : min. 21 % - Breaking energy ( ISO-V) at -40 C : min.21 J ROPETLOGGI GGI NG S G S.R.L. I BAN: Tel.: + (40) 40) 072 072221 22181 8173 73 Ploiest i RO72 BTRL 0300 2202 U767 07XX (USD) Fax: + (40 40) 24 2445956 595683 83 St r D Duca Vo a Voda 3 a 37B TRANSI LVANI A BANK, SUC PLOI ESTI w w w .ro ropet log.ro ro Prahova email: ro ropet log@gm ail.com ROM OMANI A

The steel materials used S355J2+ AR – SR EN 10025 : 2004 and S235JR – SR EN 10025 : 2004. with the following characteristics: Chemical analysis: S355J2+ AR S235JR C: max.0,18% C: max.0,18% Mn: max.1,6% Mn: max.0,80% Si: max.0,5% P: max.0,040% P: max.0,050% S: max.0,040% S: max.0,050% Mechanical characteristics: S355J2+ AR S235JR Yield point: R p0,2 : 350N/ mm 2 Yield point: R p0,2 : 350N/ mm 2 .630N/ mm 2 Tensile strength: R m : 360-400N/ mm 2 Tensile strength: R m : 510… Breaking elongation: min.22% Breaking elongation: min.22% Walls, roof, front wall and door panels are manufactured of carbon steel sheet S235JR with thickness 2mm. The walls are made from steel vertically corrugated into trapezium section and continuously welded of external container. Roof is made steel horizontally corrugated into semicircular section . The floor is realized from steel plates with thickness 4 mm. The internal floor of the cabin is covered with non slip-sheet vinyl. The floor, roof and walls are insulated with rock wool with thickness 50mm for phonic and thermal insulation and user comfort assurance. I nternal walls and ceiling are lined with 18mm MFC, colour white. The doors gaskets are weather resistant so that the dynamic characteristics remain constant in low and high temperature. 4 . RI GGI NGS The Unit shell is fitted with: - 1 off recessed frame for escape hatch, on end wall, with internal panic bar. - 1 off recessed frame for window 600x600 protection guard that forms a sun screen on opening in use - conditioned air – inverter - 12000BTU - gas detector – 2 pcs. - smoke detector – 1 pcs. - ventilator – 3 pcs. - fume cupboard - desks – 3 pcs. - shelf console - cupboard – 2 pcs. - storage area - board - sink + water installation - boiler P= 2KW ; Q= 5l/ min - off under sink water heater, and associated plumbing - fire extinguisher - convector. - internal wiring - PC network ROPETLOGGI GGI NG S G S.R.L. I BAN: Tel.: + (40) 40) 072 072221 22181 8173 73 Ploiest i RO72 BTRL 0300 2202 U767 07XX (USD) Fax: + (40 40) 24 2445956 595683 83 St r D Duca Vo a Voda 3 a 37B TRANSI LVANI A BANK, SUC PLOI ESTI w w w .ro ropet log.ro ro Prahova email: ro ropet log@gm ail.com ROM OMANI A

5 . COATI NGS ( CORROSI ON PROTECTI ON) All steel component parts and weldings were cleaned before painting, by sand blasting and cleaned as per SI S 05-59-00 class SA 2 ½ in order to remove the oil, rust, dirt and hot rolled mill scale. At inside container is applied epoxy primer coat G3282 HSFZ (70µm) and outside with primer coat and vinyl top coat RAL 9010 (200µm total). All container external lower surface was coated for sealing and corrosion prevention after installation of the floor boards. 6 . MARKI NG The container is marked in accordance with EN 12079-95. 7 . I NSURANCE QUALI TY. TESTS AND I NSPECTI ONS The product is certified by BUREAU VERITAS in accordance with the requirements of the management system standards SR EN I SO 9001. 7.1. I nspection of materials and com ponents: All materials and components are inspected by the Manufacturer’s Quality Technical Checking Department in order to ensure the container quality. 7.2. I nspection of line production All welds concerning the lifting points (corner fittings) were be checked by N.D.T. (L.P.) 7.3. PROTOTYPE TEST This container manufactured according to the execution drawings and this specification, was inspected and tested by BUREAU VERITAS in AFER Bucuresti – laboratories (Authority Railways). The testing was done in conformity with the requirements of ISO 1496-1, obtaining the CSC plate. ROPETLOGGI GGI NG S G S.R.L. I BAN: Tel.: + (40) 40) 072 072221 22181 8173 73 Ploiest i RO72 BTRL 0300 2202 U767 07XX (USD) Fax: + (40 40) 24 2445956 595683 83 St r D Duca Vo a Voda 3 a 37B TRANSI LVANI A BANK, SUC PLOI ESTI w w w .ro ropet log.ro ro Prahova email: ro ropet log@gm ail.com ROM OMANI A

Recommend

More recommend