Rare Elements in Magnetic Materials Terunobu Miyazaki WPI Advanced - PowerPoint PPT Presentation

JST Japan-EU workshop, Nov. 22, 2011 Rare Elements in Magnetic Materials Terunobu Miyazaki WPI Advanced Institute Materials Research Tohoku University My Research Experience 1972-1975 : hcp Ni, fcc Co, Fe-Co-Ni 1975-1985 : Rapidly

JST Japan-EU workshop, Nov. 22, 2011 Rare Elements in Magnetic Materials Terunobu Miyazaki WPI Advanced Institute Materials Research Tohoku University

My Research Experience • 1972-1975 : hcp Ni, fcc Co, Fe-Co-Ni • 1975-1985 : Rapidly quenched amorphous materials, Sndust (Fe-Al-Si) alloys • 1985-1991 : Amorphous thin films (Gd-Co, ・・・), Spin- glass (Fe-based alloy), Magnetiresistance (Fe,Co,Ni) • 1991-1993 : Tunnel magnetoresistance, Soft magnetic materials, Multilayer films, Kerr effect of alloy films • 1993-2007 :Tunnel magnetoresistance, (Magnetism of organic materials), (Permanent magnet), HDD, MRAM • 2007- : MRAM materials, Organic/In-organic hybrid materials

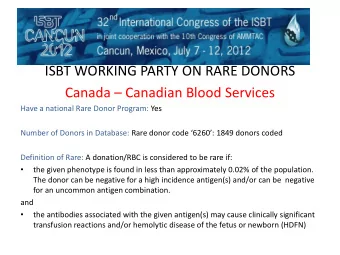

Price of the Elements used for Magnetic Materials Elements Price ($/kg) Elements Price ($/kg) B 0.65 Ga 530 N Ge 1240 Mg 2.7 (2005) Ru 1400 (2011) Al 2.2 (2010) Pd 11500 Si 2.49 Ir 37000 (2011) V 16 Pt 42100 45 → 460 Cr 7.6 Nd Mn 0.003 Sm 250 Fe 0.06 Gd 140 800 → 4900 Co 67 Tb 150 → 3800 Ni 37 Dy Zn 3.2 At 2007

Price of rare earth elements Dy Nd Nd 2005 ~ 2010 レアメタルニュース ( 発行元 : アルム出版社 )2010 年 03 月 24 日 p01 抜粋 Tb Dy June 2010 ~ August 2011

: used for magnetic materials

Classification of magnetic materials • Spintronics materials : Fe-Co-B, Heusler alloys (Co 2 MnSi), Pt-Mn, Ir-Mn, Co-Pt, Fe-Pt, CoCrPt , Mn-Ga • Hard magnetic materials : NdFeB+Dy, SmCo, FeSmN • Soft magnetic materials : Fe-Ni, Permendur (CoFe), Fe-based amorphous alloys, Sendust (Fe-Al-Si) Except oxides

Staff of Spintronics Materials Group and Collaboration TOSHIBA T. Miyazaki S. Mizukami Materials Dept. Appl. physics in Phys RIEC AIMR T. Kubota Q. Ma

Our Target Finding a new material which will be used as the electrodes of MTJ in high density MRAM M s < 300 Gauss K ⊥ = 1x10 7 erg/cc α < 0.01 TMR ratio > 100 %

Spintronics Materials for Gbit STT-MRAM Large TMR magnetic device friction Thermal fluctuation (Large write MOS-FET (Memory is lost ) current) Large perpendicular magnetic anisotropy Low magnetic friction α < 0.01 K ⊥ > 10 Merg/cc

0 Kerr signal ( arb. unit ) 3 0 0 P e r p e n d i c u l a r -10 2 0 0 -20 Kerr signal (arb. unit) M ( emu/cc ) 1 0 0 Pump laser fluence -30 I n - P l a n e 0.12 (mJ/cm 2 ) 0 -40 0.43 - 1 0 0 0.28 -50 - 2 0 0 0.83 -60 - 3 0 0 0 20 40 60 80 - 5 0 - 2 5 0 2 5 5 0 H ( k O e ) Delay time (ps) Delay time (ps) Typical magnetic and transport properties for Mn-Ga thin film (green Material) developed in our group Large ( K ⊥ =1 - 2x10 7 TMR ratio Small damping constant erg/cc ) perpendicular We must improve this α= 0.01 - 0.02 anisotropy point Wu et al, APL 94, 122503 (2009), Mizukami et al, PRL 106, 117201 (2011), Kubota et al, APEX 4, 043002 (2011)

Perpendicular magnetic anisotropy, K ⊥ > 10 Merg/cc Co 5 Sm FePt CoPt Fe 14 Nd 2 B Co 3 Pt FePd CoCrPt D. Weller et al. IEEE Trans Mag. 36 10 (2000) Noble or Rare-earth metals are crucial ?

Mn-Ga alloys exhibit large- K ⊥ as well as low- α [Co/X] N (X=Ni,Pd,Pt) α or α eff. 10 -1 Mn FePt Ga Mn MgO/CoFeB CoCrPt 10 -2 Mn-Ga 10 -2 10 -1 10 0 10 1 eff (Merg/cm 3 ) K u And also low-cost

Comparison Comparison between experiments and theory between experiments and theory 3 b 2 K u (meV/unit cell) K u ( q ) (meV/cell) minority 10 Density of states 1 ( 1/eV unit cell) 0 0 Ga Mn I Mn II -1 Mn 3 Ga -2 -10 majority -3 40 45 50 55 -6 -4 -2 0 2 q (1/cell) E-E F (eV) Electron number per cell LMTO-ASA with LDA approximation Calc. including spin-orbit interaction Mn II : 2.48 µ B K ⊥ = 26 Merg/cc M s = 306 emu/cc Mn I : -3.09 µ B Roughly consistent with exp. values S. Mizukami et al., Phys. Rev. Lett. 106, 117201 (2011).

Possible story ? story ? Possible Small damping is only around E F , (between DOS peaks) 2 ξ ( ) α ∝ SO D E F 2 ∆ E small 2 ξ ∝ SO K large ⊥ ∆ E (still under investigation)

Physics of Magnetic Materials Group (Yamagata University) Prof Kato ・ Development technology for reducing Dy usage in a rare-earth magnet METI-NEDO Project : Rare Metal Substitute Materials Development Project (H19 - H23) Yamagata Univ. + 2 Univ. +2 Institute + 4 Companies ・ Coercivity enhancement in bulk Nd-Fe-B by high-magnetic field process ・ Coercivity mechanism study by using model- interface sample made by thin-film process

Progress of energy product (BH) max

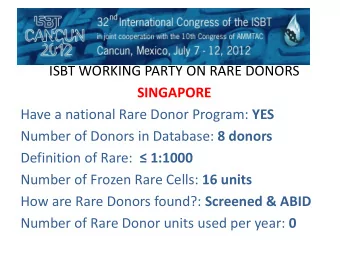

Main use and corresponding magnetic properties of Nd-Fe-B permanent magnet Operating Temperature ( ℃ ) 50 150 250 MRI, Speaker (Dy 0%) HDD, CD 50 Digital Camera (BH) max (MGOe) 45 (Dy 5%) ABS sensor OA / FA motor 40 Servo motor Robot, Generator 35 Air Conditioning Electric Vehicle (Dy 10%) 30 10 15 20 25 30 H c (kOe) required at 20 o C Natural Abundance : Dy << Nd

How to increase the coercive force without Dy? T c =310 ˚ C Nd-Fe-B permanent magnet Dy 10% Dy-free

Two approaches to increase Hc of Nd-Fe- B magnet without Dy Ⅰ.Reduction of particle size Ⅱ.Control of particle surface Disordered Reverse Uniform surface domain domain Single domain Multi-domain 90 Interface (kOe) control Hc 0.3 Particle size (μm) H c ( Dy-free Nd-Fe-B ) ≒ 10 kOe This value is approximately 10 % of the theoretically expected value

H c enhancement in Nd-Fe-B film by Nd capping t NdFeB (nm) t NFB (nm) Nd 2 Fe 14 B Nd overlayer single crystal 70 5 7 20 多 underlayer with Nd overlayer + post-annealing H c (kOe) Δ H c = 10 kOe Nd 2 Fe 14 B single crystal 多 without Nd overlayer underlayer D grain (nm)

H c versus size 100 (YU) Coercivity H c (kOe) Sintered Magnets (Intermetallics ) 10 Interface control size control 1 1 0.01 0.1 1 10 100 21 Grain Size D ( μ m)

Effect of Strong Field Gradient on H c in the grain boundary diffusion process Problems of Dy diffusion process ・ Max. diffusion depth : 3- 5 mm ・ Strong Dy-content gradient from surface to inside Any effect of mag. force by field gradient ?

Dy diffusion experiment in strong field gradient 18 T superconducting magnet Cu 0.1% Nd-Fe-B Dy(3 μ m) electric furnace T diffusion = 850 ˚ C, 60 min magnetic force: F ∝ H•dH / dz *annealed at T a =500 ˚ C after diffusion

S Dy ( K Dy < 0) c Dy ( K Dy > 0) Nd ( K Nd > 0) 土浦ら、固体物理 14 , 677 (2009), まてりあ 50 , 389 (2011)

1.5 Dy layer = 10 1.0 3 1 0.5 M / M s 0.0 -0.5 -1.0 -1.5 -2.0-1.5-1.0-0.5 0.0 0.5 1.0 1.5 2.0 H / H k

1.2 J = 9.6 meV 1 0.8 H c / H k J = 4.8 meV 0.6 0.4 0.2 0 0 2 4 6 8 10 12 14 16 18 20 Dy

How to get replaced materials ? Morphology Change Technical Methods • Multilayer film • Rapid quenching • Fine particle • Sputtering • Hybrid • MBE • Nano-porous • Atomic layer deposition • Interface control • High magnetic field processing • Topological control • ・・・ • ・・・ We need beyond We must find further these changes other new methods

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.