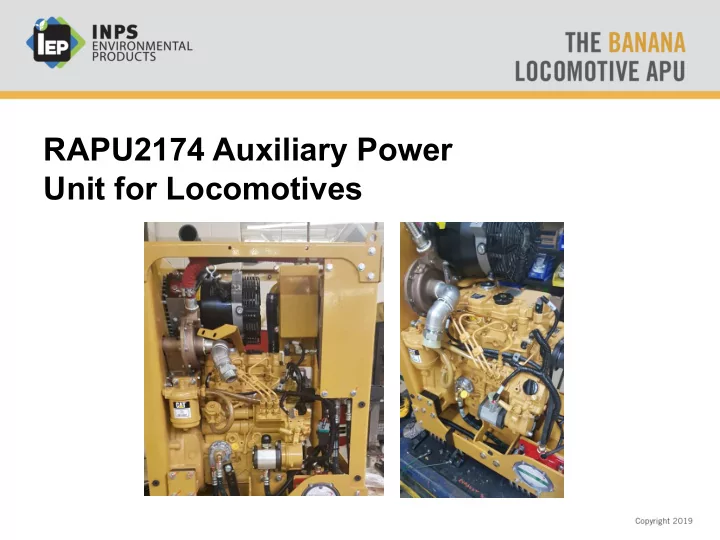

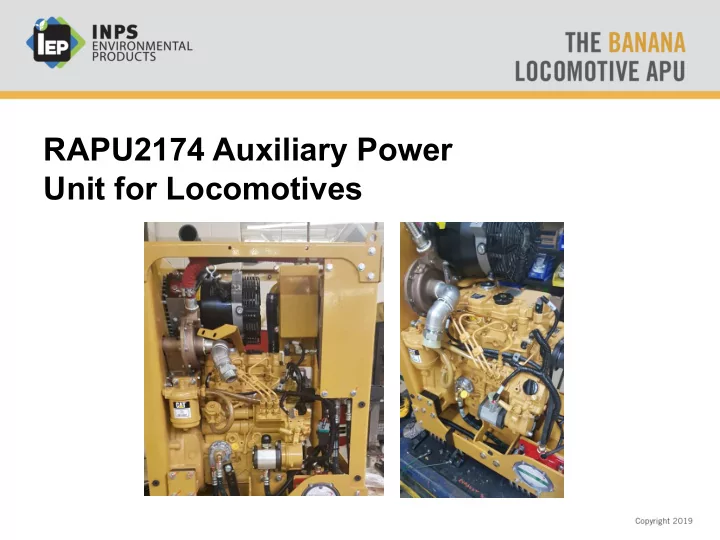

RAPU2174 Auxiliary Power Unit for Locomotives

Presentation Outline • Technology Description • Operating Characteristics • Fuel Savings • Idle Reductions • Components & Dimensions • Electrical Layout & Schematic

Technology Description • The RAPU2174 system consists of an auxiliary diesel engine/genset and an optional engine shutdown timer (EST). Together, these two components provide for a significant reduction in main engine idle time. • The system uses a water/coolant heat exchanger for APU engine cooling and main engine heating. Locomotive water pump, locomotive lube oil pump, and a fuel supply and return are part of the system. • Additional heaters are included, 6 KW for water. Locomotive oil and water are re-circulated whenever the APU runs. Locomotive batteries also receives a charge whenever the APU runs. • The APU has it’s own engine oil system. • The APU is designed to start up and shut down automatically, in response to locomotive water temperature, locomotive batteries, or operator demand.

Technology Description (Cont.) • The APU will attempt to start five times before it issues an alarm. It will also self-protect and issue an alarm for high temperature, low oil pressure, or overcrank. • The main engine shut down timer (EST), forces the main engine into a shutdown after a period of idle activity. Shortly after a shutdown, locomotive lights automatically drop out to conserve batteries.

Operating Characteristics If the following conditions exist, the EST (if equipped) will shutdown the main engine: • APU has not issued an alarm or fault • APU has a healthy 12 volt battery • APU mode selector is in either “Enabled” • APU emergency stop is pulled out • Idle exceeds 30 minutes (reverser centered for 30 minutes, no activity in trainline.) • Prior to a forced shutdown, the EST will issue three beeps, alerting an operator that a shutdown is approaching.. • Two minutes following a shutdown, the lights will drop off of the battery. A reset switch in the cab allows for re-energization of lights for two minutes.

Operating Characteristics (Cont.) • During the shutdown, the APU will remain dormant until it receives a signal to start. • The APU has two inputs to start. 1. It will start on temperature, warm up, and energize heaters and the battery charger when main engine water temperature drops to less than 27 degrees C. It will cool down and shutdown when water temperature exceeds 49 degrees C. 2. It will also start on low main engine battery voltage <62 V, this will also energize heaters (if necessary ) and the battery charger. 3. To restart the locomotive, simply follow normal starting procedures for the locomotive engine class. The APU will automatically shutdown and the EST timer will reset for the next shutdown. Note: If the APU is not “healthy” as described above, the main engine will not shutdown.

Fuel Benefits The APU saves fuel and lube oil Idle Fuel Savings • With the APU we can achieve an (test data from Southwest Research Institute) average fuel consumption reduction of 83%. In fact, the APU does not Fuel Consumption Rates Comparison at Idle run all the time when the main 30 locomotive engine is shutdown, 28 hence saving even more fuel! 25 Fuel Consumption, lbs/hr • The following example illustrates the 20 amount of fuel savings that could be 15 83% Reduction achieved. 10 4.8 5 0 GP38-2 APU

Fuel Savings for Locomotives • Consider that locomotives that idle 16 hours a day. In a year, that’s 5,840 hours of useless idle time. • Locomotives typically consume fuel when idling at an average rate of 15 L/hr. That is 88,400 Litre of fuel per year are wasted on idle for each locomotive. • The APU manages engine shutdown when the locomotive is not in operation and the auxiliary diesel engine does not have to run all the time. Field testing demonstrated that the APU engine, in the cold weather conditions, runs about a 30-40 % of engine shutdown time. In warmer regions, this will be much lower. • On average, the fuel consumption rate of the APU is 2.6 L/hr. That is, 83% less than the locomotive main engine.

Fuel Savings • Note that the previous calculations were based on the assumption that all locomotives idle 16 hours a day. • The amount of fuel savings varies depending on the locomotive duty cycle, weather conditions and battery charge. Typical fuel savings range between 47,500 L/year (for Line-Haul) and 87,000 gal/year (Switcher). • Regardless, the payback period of the APU is usually less than a year!

Noise Level Reduction • As an added benefit, the APU minimizes noise pollution that is usually associated with rail yards. • Noise generated from the APU, in normal operating mode with the locomotive car body doors shut is virtually indistinguishable from normal background noise at a distance of 100 feet.

Idle Emission Reductions (SD40-2 16-645E3 vs APU) test data from Southwest Research Institute

Idle Emission Reductions (SD40-2 16-645E3 vs APU) test data from Southwest Research Institute

Components & Dimensions

Components & Dimensions

Components & Dimensions

For more information, contact Julie Briscoe : jbriscoe@inps.net or (800) 565-3509 inps-ep.com

Recommend

More recommend