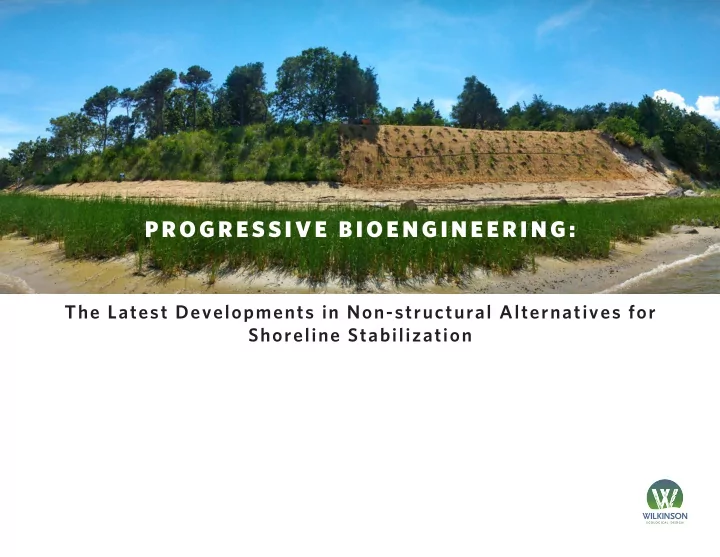

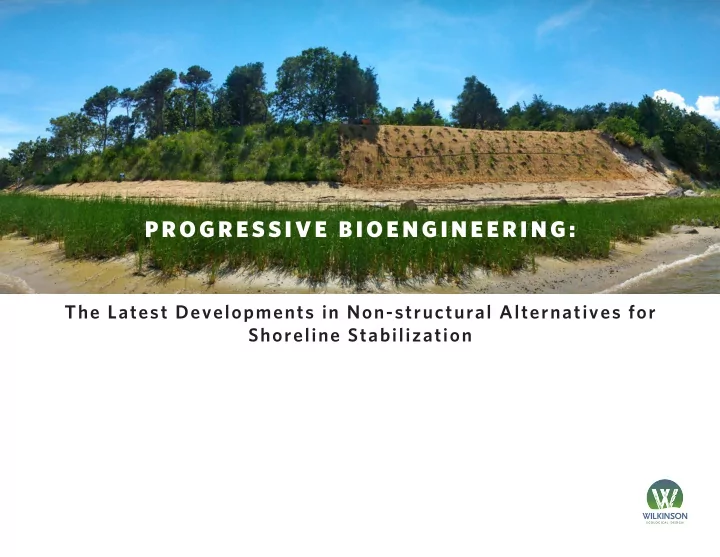

PROGRESSIVE BIOENGINEERING: The Latest Developments in Non-structural Alternatives for Shoreline Stabilization

Based on SITE SPECIFIC Criteria

Based on Site S pecific Criteria If a beach has a base elevation .

Based on Site S pecific Criteria If a beach has a base The function a fringe elevation . marsh plays.

Based on Site S pecific Criteria If a beach has a base The function a fringe Near shore characteristics like fetch, water depths, sand elevation . marsh plays. bars, and location within a given littoral cell .

Bioengin eering Strategies I mp ortance o f Fring e M ar s h es i n Coas tal S tabilizati o n

Bioengin eering Strategies I mp ortance o f Fring e M ar s h es i n Coas tal S tabilizati o n • Woven coir-fjlled mats used as a growing medium. • Pre-vegeated to establish prior before installation.

Bioengin eering Strategies I mp ortance o f Fring e M ar s h es i n Coas tal S tabilizati o n Fib er Ro ll Arra y Bea c h Eleva tio n Hig h Tid e

Bioengin eering Strategies I mp ortance o f Fring e M ar s h es i n Coas tal S tabilizati o n Fib er Ro ll Arra y Hig h Tid e

Bioengin eering Strategies I mp ortance o f Fring e M ar s h es i n Coas tal S tabilizati o n Fib er Ro ll Arra y Bea c h Eleva tio n Hig h Tid e

Install ation & Case Studies F r i nge Marshes 1

Install ation & Case Studies F r i nge Marshes 1 2

Install ation & Case Studies F r i nge Marshes 1 2 3

Install ation & Case Studies F r i nge Marshes 1 2 3 4

Install ation & Case Studies F r i nge Marshes 1

Install ation & Case Studies F r i nge Marshes 1 2

Install ation & Case Studies F r i nge Marshes 1 2 3

Bioengin eering Strategies M a terials fo r S tabilizi n g C o as tal B ank s

Bioengin eering Strategies M a terials fo r S tabilizi n g C o as tal B ank s • Coir fjber roll and reinforced fjber roll lifts add stability and protection to the toe of a bank and provides a window of opportunity to establish vegetation.

Bioengin eering Strategies M a terials fo r S tabilizi n g C o as tal B ank s • Robust anchoring systems.

Bioengin eering Strategies M a terials fo r S tabilizi n g C o as tal B ank s • Erosion control blanketing composed of natural fjbers are used to stabilize soils above the fjber rolls allowing time for native salt tolerant plants become established.

Bioengin eering Strategies M a terials fo r S tabilizi n g C o as tal B ank s • Resists degradation from the marine environment. • Absorbs some of the force of wave energy unlike many hard solutions that defmect the energy of wave action to surrounding areas. • Materials life-expectancy to stabilize sediments matches the time required to establish native plants.

Bioengin eering Strategies M a terials fo r S tabilizi n g C o as tal B ank s • Establish native plants. Nativ e G ra s s es a n d Sh ru b s P re -v eg eta ted Fib er Ro lls S al t M a rs h

Bioengin eering Strategies M a terials fo r S tabilizi n g C o as tal B ank s • Root Depths of Native Plant Species 2’ 2’ 4’ 4’ 6’ 6’ 8 ’ 8 ’ 10’ 10’ Littleblue Sideoats Switchgrass Indiangrass Big Bluestem Bayberry Stem Grama

Install ation & Case Studies

Install ation & Case Studies T y p ic al Eroding Bank 1

Install ation & Case Studies I mp ortance o f Establ is h in g a S t ab le S lo pe • Utilizing a portion of the upper bank can create a more stable slope angle. • Adds increased stability and storm damage prevention to the bank. • Without this step, an investment in bioengeneering can be lost due to bank collapses. (MA CZM Storm Smart Properties Fact Sheet 4) 1 2

Install ation & Case Studies St abilizing toe o f bank - Fib er r o lls • Installation begins at the base of the array and proceeds up bank. • Proper anchoring strategy to hold toe protection in place. • Synthetic fjlter fabrics DO NOT ENHANCE success of a bioengineering project. 1 2 3

Install ation & Case Studies St abilizing toe o f bank - P r e-veget a t ed fiber r ol l s • Use of pre-vegetated fjber rolls along top of array. • Added vegetation to the root matrix. • Full season of plant growth prior to installation. 1 2 3

Install ation & Case Studies St abilizing soi ls abo ve t o e pr o t ec t io n • Native salt tolerant grasses are seeded into the bank prior to installation of erosion control blankets. • The erosion control blankets protect soils from erosion and helps to retain moisture to promote seed germination. 1 2 3 4 LITTLEBLUE SWITCH- SIDEOATS STEM GRASS GRAMA

Install ation & Case Studies Sa nd cove r fo r fiber ro lls • Sand nourishment protects coir fjber rolls from photo-degredation “Sun Block”. • Nourishment also functions as sediment source to the adjacent coastal resource areas. 1 2 3 4 5

Install ation & Case Studies N a t ive plant spe ci es • Native beach plum and bayberry planted through erosion control blanketing. • Temporary above ground irrigation for plant establishment. 1 2 3 4 5 6

Install ation & Case Studies N a t ive plant spe ci es • Establishment of native vegetation after two seasons of growth. 1 2 3 4 5 6 7

Install ation & Case Studies • Condition of fjber roll array following Hurricane Sandy - 11/2012 1 2 3 4 5 6 7 8 Waves reached above fjber roll array with no damage.

Install ation & Case Studies • Condition of fjber roll array following named storm Nemo - 2/2013 1 2 3 4 5 6 8 9 7

Install ation & Case Studies • Condition of fjber roll array following named storm Nemo - 2/2013 1 2 3 4 5 6 8 9 7 Wa ves rea c h ed a b o ve f ib er ro ll a rra y w ith n o d a m a g e.

Install ation & Case Studies • Fiber roll array increased in length by 90’ - 6/2013 1 2 3 4 5 6 8 9 10 7 Phase 1 Phase 2

Install ation & Case Studies 1 2 3 4 5 6 8 9 10 1 1 7

Evolution of B ioengineering

Evolution of B ioengineering Sa nd E nvelo pe s

Evolution of B ioengineering Sa nd E nvelo pe s

Evolution of B ioengineering Sa nd E nvelo pe s

Evolution of B ioengineering R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2

Evolution of B ioengineering R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2

Evolution of B ioengineering R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2

Evolution of B ioengineering Evolution of B ioengineering R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4 5

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4 5 6

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4 5 6 7

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4 5

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4 5 6

Install ation & Case Studies R e in forc e d Fi ber Ro ll L ift U . S . P a t e n t N o . 1 0 , 1 2 5 , 4 6 2 1 2 3 4 5 6 7

PROGRESSIVE BIOENGINEERING: The Latest Developments in Non-structural Alternatives for Shoreline Stabilization

Recommend

More recommend