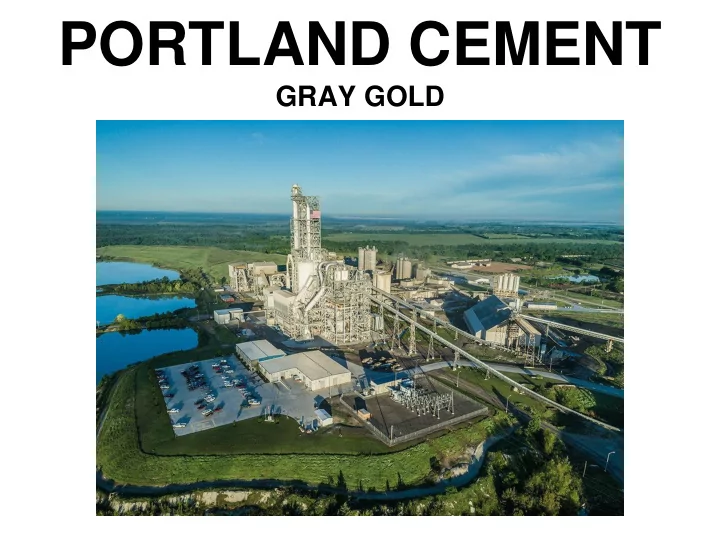

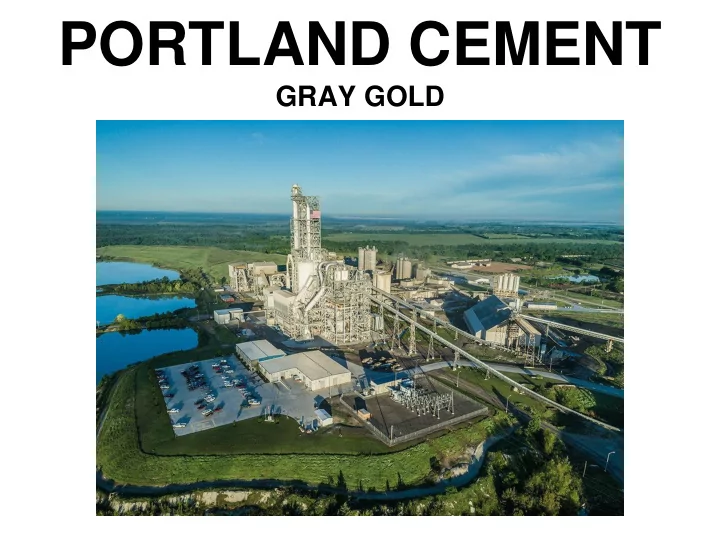

PORTLAND CEMENT GRAY GOLD

CEMENT 101 CONCRETE IS MADE FROM CEMENT, SAND, ROCKS, AND WATER THE CEMENT IS THE COMPONENT THAT “GLUES” THE MATERIALS TOGETHER

QUICK HISTORY OF CEMENT • The ancient Egyptians used calcined gypsum as a cement. • The Greeks and Romans used lime made by heating limestone and added sand to make mortar, with coarser stones for concrete. • Joseph Aspdin took out a patent in 1824 for "Portland Cement," a material he produced by firing finely-ground clay and limestone until the limestone was calcined. He called it Portland Cement because the concrete made from it looked like Portland stone, a widely-used building stone in England. • A few years later, in 1845, Isaac Johnson made the first modern Portland Cement by firing a mixture of chalk and clay at much higher temperatures, similar to those used today. At these temperatures of over 2,500 degrees f (1400C-1500C), clinkering occurs and minerals form which are very reactive and more strongly cementitious. • A ship carrying barrels of Aspdin's cement sank off the Isle of Sheppey in Kent, England, and the barrels of set cement, minus the wooden staves, were later incorporated into a pub in Sheerness and are still there now. Those who wish can sip a pint and contemplate cement history.

HOW IT IS MADE

Traditional Manufacture of Portland Cement Quarry Stone reduced to 125 mm (5 inch) Stone reduced to 20 mm (3/4 inch)

2. Raw materials are ground to powder and blended. 2. Raw materials are ground, mixed with water to form slurry, and blended. LIMESTONE (CALCIUM) – 70% CLAY/SHALE (ALUMINA) – 15% SAND (SILICA) – 10% IRON (IRON) – 5%

3. Burning changes raw mix chemically and physically into cement clinker. CALCINATION OCCURS TO THE LIMESTONE BY DRIVING OFF THE CO2 BECOMES A REACTIVE LIME MATERIAL – ABOUT 1,500 F THE KILN REACHES TEMPERATURES OF 3,000 F AND THE MOLTEN MATERIALS FORM CLINKER CLINKER IS PRODUCED AND COOLED

4. Clinker with gypsum is ground into portland cement and shipped. GYPSUM IS ADDED AT ABOUT 6% T0 10% WITH THE CLINKER GYPSUM IS ADDED TO MODERATE THE CHEMICAL REACTION WHEN WATER IS ADDED OTHERWISE THE CEMENT WOULD SET IMMEDIATELY – NOT ALLOWING ANY TIME TO MIX IT WITH THE SAND AND STONE AS WELL AS GIVING AMPLE TIME TO GET THE CONCRETE TO THE JOBSIDE AND PLACE IT.

HOW IT IS LOADED

HOW IT IS UNLOADED

US CEMENT CONSUMPTION - PRODUCTION MILLIONS OF METRIC TONS 150 DOMESTIC 140 IMPORT 130 120 TOTL 110 100 90 80 70 60 50 40 30 20 10 0 2003 2004 2005 2006 2007 2008 2009 2010 2011 2012 2013 2014 2015 2016 2017 2018

TOP 10 CEMENT PRODUCING COUNTRIES 2018 MILLIONS OF METRIC TONS 290 300 250 200 150 100 89 84 80 67 56 55 55 56 50 ???? INDIA TURKEY VIETNAM USA INDO S. KOREA JAPAN RUSSIA EGYPT

TOP 10 CEMENT PRODUCING COUNTRIES 2018 MILLIONS OF METRIC TONS 2,370 2,400 2,000 1,600 1,200 800 400 290 89 84 80 67 56 56 55 55 CHINA INDIA TURKEY VIETNAM USA INDO S. KOREA JAPAN RUSSIA EGYPT

WORLD CEMENT PRODUCTION 2018 MILLIONS OF METRIC TONS 4,100 4,200 TOTAL WORLD PRODUCTION REST OF THE WORLD 3,500 1,730 2,800 2,100 CHINA 1,400 2,370 700

TRADE FLOWS 5 5 4 US West Coast, 5+ Hawaii Canada, Great 3 1 Lakes, US East 18 6 Coast, US Gulf US Gulf, US East Coast, Canada BLACK - 2018 RED - 2006

MAYBE THE WORST

Recommend

More recommend