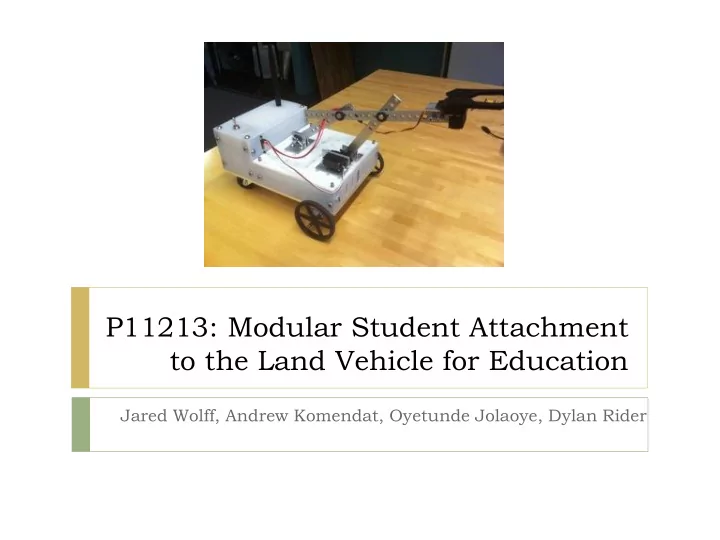

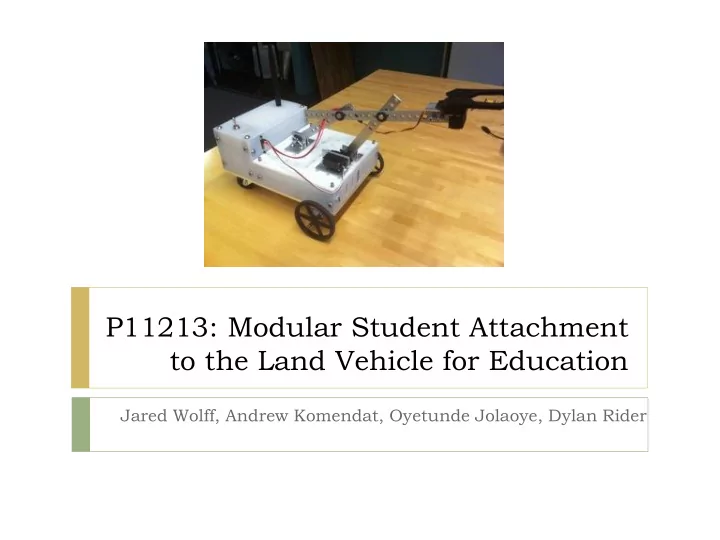

P11213: Modular Student Attachment to the Land Vehicle for Education Jared Wolff, Andrew Komendat, Oyetunde Jolaoye, Dylan Rider

Contents Project Goals Customer Needs Engineering Specifications Concept Selection Design Considerations Student Project Prototype Testing Results and Status Future Plans and Suggestions

Project Goals Attachment to Land Vehicle for Education (LVE) Introduce freshman engineers to design tools and processes Removable and interchangeable Modular Student Attachment (MSA) Utilize RIT facilities Hands on example Team project

Customer Needs Some significant customer needs: • The MSA must teach first year RIT Mechanical Engineering students design principles. • MSA must also utilize in house facilities for the manufacturing of MSA components. • MSA must be of a low cost so that more would be purchased, MSA must be easy to store in the allocated storage and it • must also be safe to use. • MSA must be impressive such that other schools and faculty would want to emulate it.

Engineering Specifications Some engineering specifications: MSA shall require each student to design, model, and manufacture 1 to 3 parts MSA shall required assembly in CAD of 5 to 15 parts MSA shall include at least 5 components MSA shall have less than 10 customable parts MSA shall require between 0.5 and 2 hours to teach per class MSA shall have not exceed 5 pounds, including payload MSA shall require less than 5 repairs during its lifetime

Concept Selection

Concept Selection

Design Considerations Feasibility and user friendliness Detailed motor and torque analysis Budget limitations LVE integration and attachment Control interfacing and communication Power consumption analysis

Mechanical Design Front/Aft Motor Interchangeable Controls integral to LVE Two motors required

Torque Analysis Calculator in Matlab Finds geometric angles based on 90 degree rotation Uses 9x9 matrix to solve for torque required Checking tool for professors to validate student design Help visualize real world limitations

Torque Analysis Standard square geometry Full range of motion No inflection point No added range in the reach

Torque Analysis Offset geometry Full range of motion Visible inflection point

Torque Analysis Offset geometry Full range of motion Visible inflection point

Power Consumption 72.2 oz in at 4.8V 90.3 oz in at 6V Worse Case Transients ~0.700 mA Normal Under Load Current ~0.500 mA 5V provided by the Buck Circuitry Power = 2*0.500 * 5V = 5W Current = 1 A

PCB Design and Layout

PCB Design and Layout

PCB Design and Layout

PCB Design and Layout

PCB Design and Layout

Control Communication USART Interface 115200 BAUD 1 stop bit Normal Inverted Operation No parity Data protocol All data is sent via UART from the LVE controller.

Structural Analysis Subject to drop requirements Limited payload weight Finite Element Analysis (FEA)

LVE Mounting Quick attachment and removal Easy to use Robust to repeated use Press fit with cotter pin

Component Selection Standardized bolt and nut sizes Off the self gripper, motors Less customized parts when possible Budget restrictions

Student Goal Lift an object from 6-9 inches off the ground between shelves across the room

Student Components and Analysis Geometric analysis Computer Aided Drafting (CAD) modeling of designed parts CAD assemblies using parts library available Manufacturing Assembly and test

Student Components and Analysis Links Brackets Student Made Pins Student Made Student Made

Student Components and Analysis

Prototype

Prototype

Prototype

Testing Test plan includes 18 tests Passed all tests Survey Feedback from ME Professors P11211-P11213 Land Vehicle for Education (LVE) Megan Ott and Andrew Komendat Response # Question #1 Question #2 Question #3 Question #4 Question #5 1 5 4 - 4 2 2 4 5 4 4 5 3 4 5 3 3 4 4 3 5 4 - 3 5 4 4 5 5 3.5 6 TOTALS 80.00% 92.00% 80.00% 80.00% 70.00% GRAND TOTAL 80.43%

Testing 10/3 time to complete ratio Scrap material

Results and Conclusions Working prototype Lacks robustness in strength and durability Budget restrictions were overlooked Fun project Room for improvement Contains potential multidisciplinary projects

Future Suggestions and Improvements Better material selection color for aesthetics Manufacture gripper in house (cost reduction) More robust and capable drive servo Decrease size and capability of MSA Improve multidisciplinary projects

Acknowledgements Special Thanks To: Guides: Phil Bryan Leo Farnand Vince Burolla Sponsors and Faculty Advisors Dr. Edward Hensel Dr. Beth Debartolo

Recommend

More recommend