On the nature of suboxide formation during reactive DC magnetron - PDF document

On the nature of suboxide formation during reactive DC magnetron sputtering R. Schelfhout, K. Strijckmans, D. Depla Dedicated Research on Advanced Films and Targets Ghent University Introduction In-vacuo XPS target analysis Ion Beam Oxidation

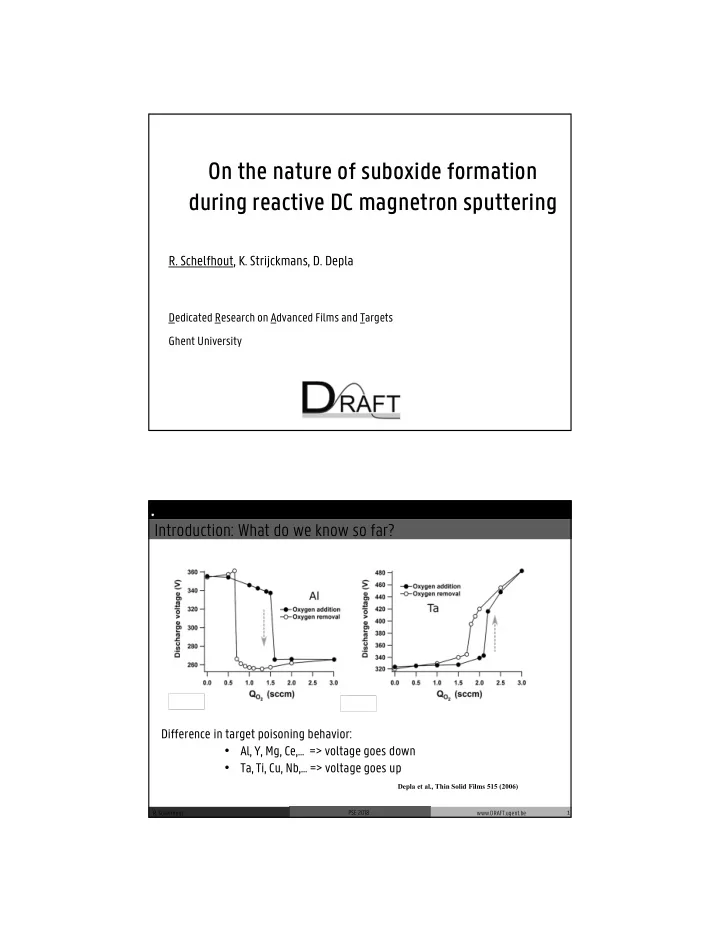

On the nature of suboxide formation during reactive DC magnetron sputtering R. Schelfhout, K. Strijckmans, D. Depla Dedicated Research on Advanced Films and Targets Ghent University Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Introduction: What do we know so far? Difference in target poisoning behavior: • Al, Y, Mg, Ce,… => voltage goes down • Ta, Ti, Cu, Nb,… => voltage goes up Depla et al., Thin Solid Films 515 (2006) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 1

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Introduction: What do we know so far? About DC magnetron discharges: Strong correlation between target (γ ISEE ) and discharge voltage 1 � = �� ���� + � (for fixed discharge conditions) J. A. Thornton, J. Vac. Sci. Technol. 15 (2), (1978) G. Buyle, “Simplified model for the DC planar magnetron discharge”, PhD Dissertation, UGent, 2005 Altering (reactive) DC magnetron discharge Sputter cleaning experiments Depla et al., Thin Solid Films 515 (2006) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 2 Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Introduction: What do we know so far? data taken from: Depla et al., Sputter reduction of oxides Surface and Coatings Technology 200 (2006) R a) R b) by noble ion bombardment : 1.50 1.46 2.22 1.26 Reduction factor R 2.50 1.25 1.50 1.12 ⁄ � � � � � R = 1.33 1.33 ⁄ � � � � � 1.00 1.05 2.26 1.12 R ≥ 1.05: reduction 1.11 1.00 R = 1.00: no reduction 1.00 1.00 1.22 1.00 1.00 a) Malherbe et al., Appl. Surf. Sci. (1990) b) Mitchell et al., Surf. Interface Anal. 15 (1990) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 3

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Introduction: What do we know so far? Do reduced oxides have a low γ ISEE ? + on Si Ion beam sputtering experiments: 5 or 3 keV O 2 metal γ ISEE, oxide > γ ISEE, metal > γ ISEE, suboxide suboxide oxide relative concentration (%) electron yield (el./ion) impact angle (deg) impact angle (deg) Alay et al., Phys. Rev. B 50 (20), (1994) Wittmaack, Surface Science 419 (1999) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 4 Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Introduction: What do we know so far? The Hypothesis: “The discharge voltage behavior upon target poisoning is linked to the target oxide stoichiometry” Depla et al., J. Appl. Phys. 101, (2007) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 5

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion In-vacuo XPS determination of the target surface target anode ring 1” magnetron anode ring holder transfer stick target holder matching XPS dimensions R. Schelfhout PSE 2018 www.DRAFT.ugent.be 6 Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion In-vacuo XPS determination of the target surface Sputter conditions: • 1” magnetron P back = 3 x 10 -4 Pa P back = 4 x 10 -6 Pa • S = 30 l/s • P tot = 1 Pa • P O2 varied • I = 70 mA (constant DC) XPS specifications : • Surface Science Instruments (VG) S-probe • Monochromated Al Kα P back = 1.6 x 10 -7 Pa • Pass energy = 39.7 eV, resolution = 0.05 eV • Spot size in center of racetrack 250 x 1000 µm² • no charge compensation • transfer time < 5 min hardly any contamination (XPS confirmed) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 7

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion In-vacuo XPS determination of the target surface Ta 4f 7/2 Ta 4f 5/2 Al 2p 3/2 Al 2p 1/2 different stoichiometry's stoichiometric Al 2 O 3 (Al 3+ ) surface (Ta 5+ ,…,Ta 0+ ) at the surface metal (Al 0+ ) from bulk Schelfhout et al., Surface and Coatings Technology 353 (2018) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 8 Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion In-vacuo XPS determination of the target surface The Hypothesis: Depla et al., Surface and Coatings Technology 200 (2006) “The discharge voltage behavior upon target poisoning is linked to the target oxide stoichiometry” XPS analysis on target surface: Schelfhout et al., Surface and Coatings Technology 353 (2018) “Direct experimental confirmation of suboxide occurrence on the target + elaborated discussion on its impact on γ ISEE ” However, the hypothesis is based on sputter reduction of the native oxide (IBR) but during reactive DC magnetron sputtering, the metallic bulk continuously oxidizes (IBO) PSE 2018 R. Schelfhout www.DRAFT.ugent.be 9

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Ion Beam Oxidation (IBO) Ion Beam Oxidation (IBO) = oxidation by reactive gas implantation Oxygen concentration is inversely proportional to the metal sputtering yield Y m � �,� ~ � � = 1 � �,� � � � � Y m high n O,s ≈ 0 metal Y m interm. n O,s = small suboxide Y m low n O,s = high oxide Janssens et al., Surface Science 601 (2007) R. Schelfhout PSE 2018 www.DRAFT.ugent.be 10 Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Ion Beam Oxidation (IBO) Ion Beam Oxidation (IBO) = oxidation by reactive gas implantation metal oxide suboxide oxide suboxide metal sputtering yield (Si/ion) relative concentration (%) impact angle (deg) impact angle (deg) Alay et al., Phys. Rev. B 50 (20), (1994) Wittmaack, Surf. Inter. Analysis 29 (2000) The lower the silicon sputtering yield, the higher the oxidation degree R. Schelfhout PSE 2018 www.DRAFT.ugent.be 11

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Reactive DC magnetron sputtering What about reactive magnetron sputtering? 1 ≈ � �,� = �′ z’ = “average oxide stoichiometry” IBO (f O2 = 1): � � � �,� 2 � � � � � � = IBO equivalent in � � � � � �� reactive magnetron sputtering: v s n O (x) (assuming all oxygen reacts (lower limit)) 2�� � � = �′�� � P(x) which is the oxygen balance between the implanted in and sputtered out The higher f O2 (constant Y m ), the higher the oxidation degree R. Schelfhout PSE 2018 www.DRAFT.ugent.be 12 Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Suboxide formation during reactive DC magnetron sputtering Aluminum Alternative definition reduction factor R: (assuming all oxygen reacts (lower limit)) R>1 � � ⁄ �� �� � � � � � � R = � = � = ⁄ � � � � � � � R<1 z’ = “average oxide stoichiometry” or what is actually on the target z = “native oxide stoichiometry” or what could be formed on the target Target generally poisons below f O2 = 0.1 experimental procedure published in Schelfhout et al., J. Phys. D: Appl. Phys. 51 (2018) R<1: too few oxygen implanted suboxide formation R>1: excess oxygen implanted stoichiometric oxide formation Al at f O2 = 0.1 R. Schelfhout PSE 2018 www.DRAFT.ugent.be 13

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Suboxide formation during reactive DC magnetron sputtering Tantalum Alternative definition reduction factor R: (assuming all oxygen reacts (lower limit)) R>1 � � ⁄ �� �� � � � � � � R = � = � = ⁄ � � � � � � � R<1 z’ = “average oxide stoichiometry” or what is actually on the target z = “native oxide stoichiometry” or what could be formed on the target Target generally poisons below f O2 = 0.1 experimental procedure published in Schelfhout et al., J. Phys. D: Appl. Phys. 51 (2018) R<1: too few oxygen implanted suboxide formation Ta at f O2 = 0.1 R>1: excess oxygen implanted stoichiometric oxide formation Al at f O2 = 0.1 R. Schelfhout PSE 2018 www.DRAFT.ugent.be 14 Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Suboxide formation during reactive DC magnetron sputtering Alternative definition reduction factor R: (assuming all oxygen reacts (lower limit)) �� �� � � � � ⁄ �� � � R = � = � = � � � � ⁄ � � � if f O2 becomes large enough, Ta 2 O 5 can be formed f O2 > 0.5 : • XPS confirms stoichiometric oxide • The discharge voltage lowers again R. Schelfhout PSE 2018 www.DRAFT.ugent.be 15

Introduction In-vacuo XPS target analysis Ion Beam Oxidation Reactive magnetron sputtering Conclusion Conclusion and Acknowledgements • Experimental confirmation suboxide occurrence by in-vacuo target surface XPS analysis • Ion Beam Oxidation (IBO) as alternative mechnanism for suboxide formation • The absolute magnitude of the sputter yield after target poisoning determines the target stoichiometry R. Schelfhout PSE 2018 www.DRAFT.ugent.be 16

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.