NORMAL-/SHEAR-DECOHESIVE DAMAGE OF ADHESIVELY BONDED JOINTS AT - PDF document

18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS NORMAL-/SHEAR-DECOHESIVE DAMAGE OF ADHESIVELY BONDED JOINTS AT ROOM/CRYOGENIC TEMPERATURES C. S. Lee 1 , J. M. Lee 1 * 1 Dept. of Naval Architecture and Ocean Engineering, Pusan National

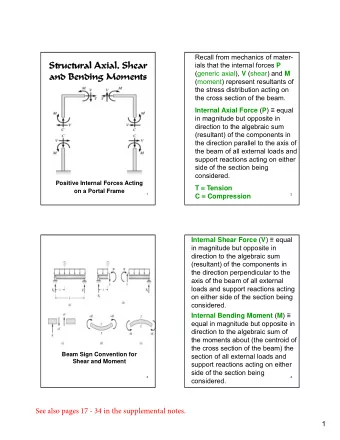

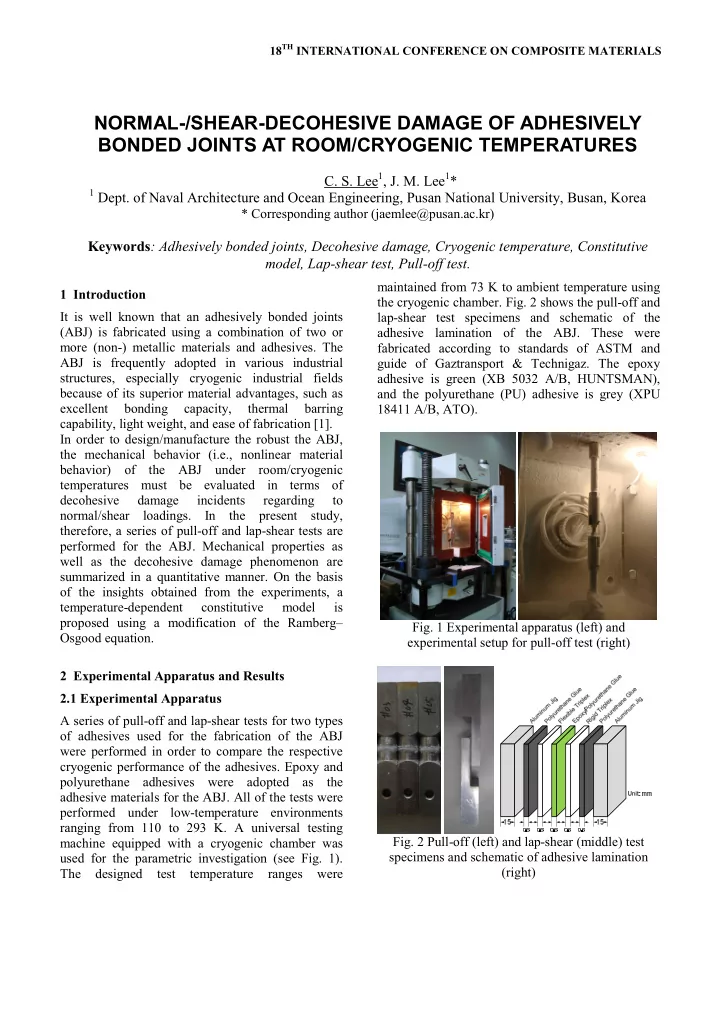

18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS NORMAL-/SHEAR-DECOHESIVE DAMAGE OF ADHESIVELY BONDED JOINTS AT ROOM/CRYOGENIC TEMPERATURES C. S. Lee 1 , J. M. Lee 1 * 1 Dept. of Naval Architecture and Ocean Engineering, Pusan National University, Busan, Korea * Corresponding author (jaemlee@pusan.ac.kr) Keywords : Adhesively bonded joints, Decohesive damage, Cryogenic temperature, Constitutive model, Lap-shear test, Pull-off test. maintained from 73 K to ambient temperature using 1 Introduction the cryogenic chamber. Fig. 2 shows the pull-off and It is well known that an adhesively bonded joints lap-shear test specimens and schematic of the (ABJ) is fabricated using a combination of two or adhesive lamination of the ABJ. These were more (non-) metallic materials and adhesives. The fabricated according to standards of ASTM and ABJ is frequently adopted in various industrial guide of Gaztransport & Technigaz. The epoxy structures, especially cryogenic industrial fields adhesive is green (XB 5032 A/B, HUNTSMAN), because of its superior material advantages, such as and the polyurethane (PU) adhesive is grey (XPU excellent bonding capacity, thermal barring 18411 A/B, ATO). capability, light weight, and ease of fabrication [1]. In order to design/manufacture the robust the ABJ, the mechanical behavior (i.e., nonlinear material behavior) of the ABJ under room/cryogenic temperatures must be evaluated in terms of decohesive damage incidents regarding to normal/shear loadings. In the present study, therefore, a series of pull-off and lap-shear tests are performed for the ABJ. Mechanical properties as well as the decohesive damage phenomenon are summarized in a quantitative manner. On the basis of the insights obtained from the experiments, a temperature-dependent constitutive model is proposed using a modification of the Ramberg– Fig. 1 Experimental apparatus (left) and Osgood equation. experimental setup for pull-off test (right) 2 Experimental Apparatus and Results 2.1 Experimental Apparatus A series of pull-off and lap-shear tests for two types of adhesives used for the fabrication of the ABJ were performed in order to compare the respective cryogenic performance of the adhesives. Epoxy and polyurethane adhesives were adopted as the adhesive materials for the ABJ. All of the tests were performed under low-temperature environments ranging from 110 to 293 K. A universal testing Fig. 2 Pull-off (left) and lap-shear (middle) test machine equipped with a cryogenic chamber was specimens and schematic of adhesive lamination used for the parametric investigation (see Fig. 1). (right) The designed test temperature ranges were

2.2 Design of Experiments As previously mentioned, two types of ABJ are frequently adopted in industrial fields. The material behaviour, including the debonding failure characteristics, of these types of ABJ is the primary (a) Type A, 293K subject of this paper. The two types of lamination structures are described in Table 1. The test scenarios were categorised into pull-off and lap- shear cases, and they are summarised in Tables 2 and 3. Each test was performed under varying (b) Type A, 163K temperatures (293, 163, and 110 K). In order to ascertain the repeatability of the test results, the tests in each case were performed seven times. Table 1 Description of lamination types Type of (c) Type A, 110K Description ABJ Polyurethane + Flexible triplex + Epoxy + Rigid triplex + Type A Polyurethane Polyurethane + Flexible triplex + Polyurethane + Rigid Type B triplex + Polyurethane (d) Type B, 2930K Table 2 Test case for the pull-off test Title Temperature Adhesion area of Type of ABJ (mm 2 ) (K) test Type A 293 121.7 (e) Type B, 163K 121.7 Type A 163 Pull- 121.7 Type A 110 off 121.7 Type B 293 test 121.7 Type B 163 121.7 Type B 110 (f) Type B, 110K Fig. 3 Photographs of the debonded surface of the Table 3 Test case for the lap-shear test pull-off test specimen Title Temperature Adhesion area of Type of ABJ (mm 2 ) (K) test Type A 293 2500 3 Constitutive Model Type A 163 2500 Lap- Type A 110 2500 The temperature-dependent modified constitutive shear Type B 293 2500 test model which is based on Ramberg-Osgood [2] is Type B 163 2500 proposed as follows: Type B 110 2500 n(T) σ,τ(T) -σ ,τ (T) 2.3 Test Results and Discussion σ,τ(T) Y Y ε,γ= + sgn(σ,τ) (1) E,G(T) E',G'(T) Figs. 3 to 6 show the debonded surface and the stress with σ,τ(T)=σ ,τ (T), and strain relationship obtained from the pull-off and s s lap-shear tests at each temperature. In the present where σ Y /τ Y is the normal/shear yield stress, E′/G′ is study, the normal and shear stresses are mean the normal/shear stress coefficient, n/m is the stresses, i.e., the stress is simply calculated normal/shear softening coefficient, σ s /τ s is the according to applied force divided by the adhesion normal/shear plastic threshold stress, and < > are area. The obtained test results of each adhesive Macaulay parentheses. Table 6 lists the material according to temperature and loading direction are properties of Eq. (1). discussed in Tables 4 and 5.

PAPER TITLE Table 4 Obtained test results of each ABJ according to normal loading Type of ABJ Room temperature · The debonding occurred between the epoxy adhesive and the flexible/rigid triplex in approximately 50% of the cases. · Nearly half of the debonding cases occurred between the polyurethane adhesive and the Type A flexible/rigid triplex. This means that the normal (a) Type A, 293K (b) Type A, 163K bonding strength of both adhesives is nearly the same. This can be seen in Fig. 5. · The debonded surface is very clear and there is no tearing of the epoxy adhesive. · All of the debonding occurred between the polyurethane adhesive and the flexible/rigid Type B triplex. · The debonded surface is very clear and there is no tearing of the polyurethane adhesive. Type of ABJ Cryogenic temperature (c) Type A, 110K (d) Type B, 293K · All of the debonding occurred between the epoxy adhesive and the flexible/rigid triplex. This means that the normal bonding strength of polyurethane adhesive is greater than that of epoxy adhesive. · As in the room temperature case of both Type A Type A and Type B, the debonded surface is very clear and there is no tearing of the epoxy adhesive. · It is interesting that the normal strain of Type A is almost unaffected by temperature. Only an increase of the normal stress is observed in Type A. (e) Type B, 163K (f) Type B, 110K · As in the room temperature case, all of the Fig. 4 Photographs of the debonded surface of the debonding occurred between the polyurethane lap-shear test specimen adhesive and the flexible/rigid triplex. · However, the debonded surface is not clear, and Type B there is tearing of the polyurethane adhesive. It is 20 20 believed that the adhesion strength of the TYPE B 293K EPOXY 293K TYPE B 163K EPOXY 163K polyurethane adhesive at cryogenic temperatures TYPE B 110K EPOXY 110K 16 16 under normal loading is stronger than it is in the other cases. This can be seen in Fig. 5. Normal stress (MPa) Normal stress (MPa) 12 12 · As the temperature decreases, the elastic stiffness/tensile strength increases. 8 8 · As the temperature decreases, the polyurethane adhesive exhibits normal strength that is higher Overall 4 than that of epoxy adhesive. 4 discussion · Epoxy adhesive gives almost equal values of normal strain for all of the test temperatures. 0 0 0 0.01 0.02 0.03 0.04 0.05 0 0.01 0.02 0.03 0.04 0.05 Normal strain Normal strain However, the fracture strain of the polyurethane (a) Type A (b) Type B adhesive increases as the temperature decreases. Fig. 5 Relationship between normal stress and strain in the pull-off test The ten temperature-dependent parameters obtained 30 30 from Eq. (1) can be represented as a linearized TYPE B 293K EPOXY 293K TYPE B 163K EPOXY 163K funciont of the temperature-dependent material TYPE B 110K EPOXY 110K coefficient, as follows: 20 20 Shear stress (MPa) Shear stress (MPa) ì ü E ,G ì ü ì E,G(T) ü a ,b 0 0 1 1 ï ï ï ï ï ï 10 10 σ ,τ σ ,τ (T) a ,b ï ï Y0 Y0 ï ï ï ï Y Y 2 2 ï ï ï ï ï ï ' ' * (2) í E',G'(T) ý = í E ,G ý +T í a ,b ý , 0 0 3 3 ï ï ï ï ï ï 0 0 0 0.04 0.08 0.12 0.16 σ ,τ (T) σ ,τ a ,b 0 0.04 0.08 0.12 0.16 ï ï ï ï ï ï Shear strain Shear strain T T T0 T0 4 5 (a) Type A (b) Type B ï ï ï ï ï ï n,m(T) n ,m a ,b î þ î þ î þ 0 0 5 5 Fig. 6 Relationship between shear stress and strain in the lap-shear test 3

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.