New Tools for Aroma Barrier Testing Mika Vh-Nissi T. Hjelt, M. - PowerPoint PPT Presentation

New Tools for Aroma Barrier Testing Mika Vh-Nissi T. Hjelt, M. Jokio, R. Kokkonen, J. Kukkonen, A. Mikkelson 1 08.03.2007 What is KCL? Located in Espoo, Finland Founded in 1916 Staff 300 Research areas: Fibers

New Tools for Aroma Barrier Testing Mika Vähä-Nissi T. Hjelt, M. Jokio, R. Kokkonen, J. Kukkonen, A. Mikkelson 1 08.03.2007

What is KCL? • Located in Espoo, Finland • Founded in 1916 • Staff 300 • Research areas: – Fibers – Papermaking solutions – Printing surfaces – End-use environment – Composite/ packaging materials • Owners: 08.03.2007 2

Contents of presentation Motivation • Motivation for barrier studies? • Why are aromas challenging? • How to measure aroma barrier? Test methods used for aroma barrier studies Case: Effect of base paper and paperboard Concluding remarks 08.03.2007 3

Motivation for barrier studies? • Need to optimize existing materials: – Cost and environmental issues – Global business and new retailing channels – Current packaging solutions for new products • Need to develop new materials: – New materials emerging – true performance? – Transformation from “passive” to “active” – Packaging concepts and processes changing 08.03.2007 4

What makes aromas challenging? • Important characteristic of flavor and foods – Even small inbalance detrimental to food quality • Aromas consist of volatile organic compounds – From tens to over thousand different compounds • No widely accepted test methods or specifications for aroma transfer into/ through materials • Correlation with other barrier properties at best indicative 08.03.2007 5

Permeation methods utilizing various detectors • For nonporous materials • Also porous substrates (continuous flushing) • No steady-state - • Reaching steady-state concentration gradient permeation changes • Commercial systems based on this have existed 08.03.2007 6

Sorption methods • Solubility and diffusion of single materials • Only qualitative comparison of multilayer materials 08.03.2007 7

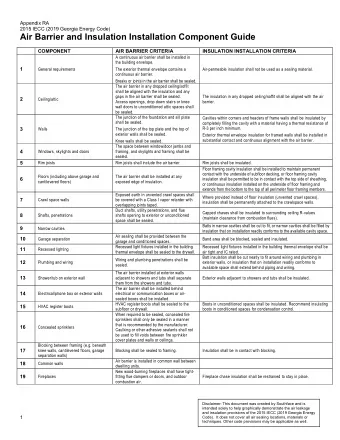

Test methods used for aroma barrier 1) Gravimetric method Permeation 2) Desiccator method Solubility/ diffusion 3) Permeation cell Diffusion � AromaBar (solubility) 08.03.2007 8

Desiccator method - sorption/ desorption Procedure: • Samples exposed to aroma • Allowed to desorb for specific time • Analyzed with HS-GC or extraction Pros: • For aroma blends & single aromas • Diluted concentrations Cons: • Porous materials more difficult • Not suitable for coated materials 08.03.2007 9

Permeation cell – manual quasi-isostatic method Procedure: • Two subcells, sample between • Samples removed manually with gas-tight syringe and injected into CG Pros: • For aroma blends & single aromas • Diluted concentrations • For uncoated and coated paper/ board, and polymer films Cons: • Manual sampling and leakages • No temperature/ humidity control 08.03.2007 10

AromaBar – improved method for barrier tests Sample Cell 2 3 transfer oven 1 Test cell oven Control unit Tem p. m ax. 1 5 0 ° C Tem p. m ax. 6 0 ° C GC Sample 3 Aromas 1 GC/ FID 2 • Transfer from vapor contact • Controlled temperature and humidity • Automatic gas sampling • No interfering continuous • For uncoated and coated paper carrier gas flows and board, and polymer films 08.03.2007 11

AromaBar vs. Permeation cell methods Improved data quality: Concept same • Follow concentration in receiving cell • Mathematical analysis to obtain diffusion coefficients ( D ) Improved repeatability • Standard deviation for 5 tests with LDPE coated paper ∼ 10 % • Better control of test procedure Improved usability ( ) ⎛ ⎞ ⎛ ⎞ − + + π ∞ 2 ( n 1 ) 2 ( ) 2 2 ( 1 ) 2 1 M t ∑ L n Dt ⎜ ⎟ ⎜ ⎟ = + − Temperature/ humidity control 1 exp ( ) ⎜ ⎟ ⎜ ⎟ + π 2 2 1 ⎝ 4 ⎠ M L n L ⎝ ⎠ = n 0 Max 08.03.2007 12

One aroma compound not enough… Aroma compounds : different structures/ polarities, representative, safe and suitable for GC analysis Stability of single compounds need special attention! 08.03.2007 13

Diluted model solutions as aroma sources w-% % Diluted to lower vapor concentrations in order to avoid swelling of polymer (aim relative vapor pressures ≤ 10 % ) Lower concentrations for tests at elevated temperatures 08.03.2007 14

Case Role of base sheet in aroma barrier • ”Base sheet has no effect on barrier!” • PE and dispersion coated papers excellent barriers against inert gases – w hat about arom as? • Possible to make some barrier already on paper and paperboard machine? If base sheet has an effect on aroma barrier: • Diffusion coefficient calculated based on coating thickness decreases • Is surface or total porosity more important? 08.03.2007 15

Case Set 1 for Permeation cell and Desiccator tests Set 1 Set 2 for AromaBar Set 2 08.03.2007 16

Case Analysis of coated sheets from cross-cuts Porosity profile of base sheet and total porosity, coating thickness and thickness distribution 08.03.2007 17

Case Base sheet decreases diffusion Example from AromaBar tests with aroma blend 08.03.2007 18

Case Coating thickness variation not important… 08.03.2007 19

Case Surface rather than total porosity of base sheet affects diffusion Relative D (limonene) of PE coating vs. base sheet porosities Relative D of limonene vs. base sheet porosities � AromaBar, 100 g/ m 2 sheets ♦ Permeation cell, 80 g/ m 2 sheets 08.03.2007 20

Case Aroma loss via solubility determined by polymer • Determined by polymer in contact with aroma • Aroma compounds compete over sorption sites • Solubility of compounds (carvone and d-limonene) to fibers low 08.03.2007 21

Concluding remarks • Aromas: numerous compounds at low concentrations with different affinities to foods and packaging materials • New sorption and quasi-isostatic permeation test methods for aroma vapor barrier developed • Base sheet decreases diffusion of aroma compounds through PE coated sheets: – Surface rather than total porosity of base sheet important – Potential to improve barrier further (e.g. HD paper) • Solubility of typical compounds (carvone, limonene) into fibers low 08.03.2007 22

Thank You for Co-Authors… E-mail: name.name@kcl.fi 08.03.2007 23

… laboratorians/ technicians who made it possible, … SUSTAINPACK EU-project for supporting part of this study, … and Borealis Polymers for providing us with polyethylenes 08.03.2007 24

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.