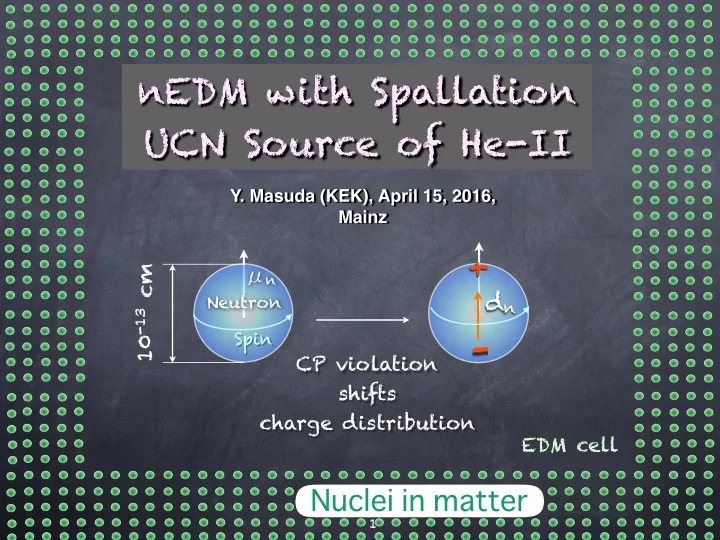

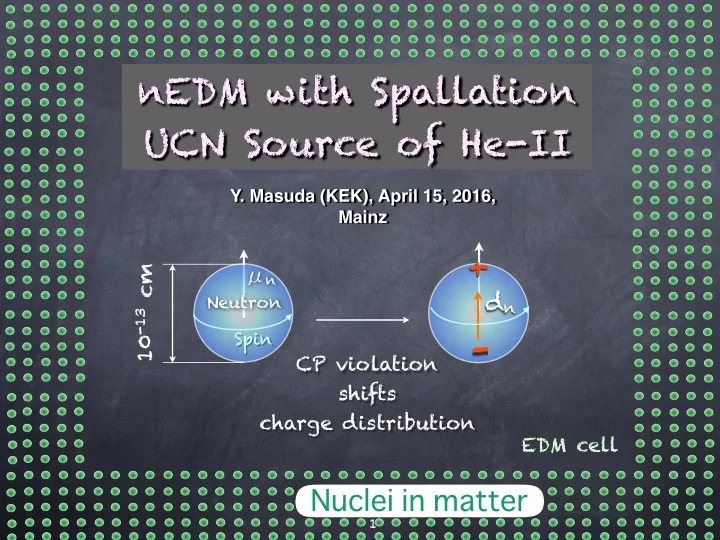

nEDM with Spallation UCN Source of He-II Y. Masuda (KEK), April 15, 2016, Mainz + 10 -13 cm μ n d n Neutron Spin - CP violation shifts charge distribution EDM cell Nuclei in matter 1

nEDM upper limit Theoretical History of nEDM predictions 10 -20 10 -20 Cold n beam 10 -22 10 -22 10 -24 10 -24 UCN 10 -26 e cm 10 -26 ρ = 1 UCN/cm 3 10 -28 1950 1950 2000 Year 800 UCN/cm 3 10 -30 Pendlebury A He-II UCN source e cm 2

Our EDM measurement The difference ( ω - ω o )t c is measured by polarimetry: δ d sta = h /{2 P n Et c √ N } Statistical error: 1. N , He-II spallation UCN source 10 -27 ~10 -28 e cm 2. P n , Magnetic extraction of UCN from He-II 10 -27 e cm Systematic error: 3. B 0 monitor, 129 Xe co-magnetometer 2nd π /2 ω t c RF phase 1st π /2 ω o t c precession phase B o E spin s 1 10 μ T kV /cm ( ω - ω o )t c S matrix: phase operator U(t) = exp{i( μ· B 0 + d n ∙ E) ∙ t/h} rotation operator μ , d n ∝ s EDM cell 3

Our nEDM apparatus 2. Magnetic extraction of UCN μ B 0 (3.5T) = 210 neV > V F (Al)=54 neV UCN valve is closed 3. 129 Xe co-magnetometer during production Ramsey resonance EDM cell SCM Vacuum He-II B o E Al foils Polarized UCN P UCN ~ 100% 20K D 2 O 10K D 2 O V F (guide)= 210 neV Rotary 12L He-II valve Spin 300K 1. UCN production in He-II analyzer D 2 O Target N ∝ production rate ∝ E p × I p N ∝ production time ∝ τ s δ d sta = h /{2 P n Et c √ N } proton beam

P = 200 UCN/cm 3 /s, τ s = 100 s in 12 L He-II at E c = 210 new ρ pol = 800 UCN/cm 3 in EDM cell of E c = 90 neV Energy deposit upon spallation reaction ρ = P τ s ρ P 10K D 2 O He-II p beam → τ s t target Target He-II 10K D 2 O P (production rate) = ∫∫ d E in d E UCN Proton beam power N σ ( E in → E UCN )d Φ n ( E in )/d E in 400MeV × 1 μ A 0.1 W 4.4 W ∝ E p × I p 400MeV × 10 μ A 1 W 44 W 500MeV × 40 μ A 5 W 220 W (our goal) He-II bottle wall is dominant 5

He-II phonon up-scattering Longer UCN Golub, 1983 36 s production 64 s τ ph = 600 s at 0.8 K 123 s 1.2 K τ s (UCN lifetime) 250 s 1.1 K = 1/{1/ τ β + 1/ τ 3He + 1/ τ w + 1/ τ ph } = 174 s 600 s 1 K τ β = 886 s ( β decay) τ 3He = 28 ms at 3 He/ 4 He = 1.4x10 -6 0.9 K 1370 s = 3900 s at 3 He/ 4 He = 10 -11 0.8 K τ w = 246 s (wall loss) 0.7 K Z. Phys. B59(1985)261 We are aiming at τ s = 100 s 6 = 174 s

Isopure PulseTube 3 He 4 He 4He pumping cryostat He-II cooling at 0.8 K 3 He pumping 3 He Proton beam Heat 3 He flow cryostat power He-II 400MeV × 1 μ A 0.1 W 400MeV × 10 μ A 1 W EDM pumping 0.032 mol/s cell 500MeV × 40 μ A 5 W 0.16 mol/s 3 He Liq.He our goal Door valve Heat load is 1K removed upon pot SCM 3 He evaporation. 8L polarizer pot 20K D 2 O 10K D 2 O Heating γ heating are 300K D 2 O conducted 3 He- 4 He UCN Target Heat through He-II valve exchanger UCN detector 7

valves 4He pumping needle 3 He of 0.16 mol/s at E p × I p = 20 kW is returned to cryostat 10 4 m 3 /h pump φ 12 → φ 25 3 He reserver 0.24 mol/s at 0.7 K 0.16 mol/s φ 12 3 He filling 3 He PulseTube pumping Isopure 4 He 3 He Pre-cooling from 300K Liq.He to 30K 1K pot 3 He- 4 He 8L Cooling power heat pot 20K D 2 O 10K D 2 O exchanger 3 He evaporation rate Heating He-II γ heating are conducted through He-II T a r g e t

4 He Isopure Tube Pulse 3 He 4He pumping Present status of our UCN source 3 He cryostat EDM pumping UCN source cell 3 He GM cryostat Liq.He Door valve 1K Exhaust pot SCM valve for polarizer 8L bottle cleaning pot 20K D 2 O 10K D 2 O He-II 300K D 2 O 3 He- 4 He UCN Heat Target valve exchanger Graphite Concrete Steel UCN detector 9

Photo of our UCN source 3 He cryostat UCN source Heat Superconducting exchanger magnet He-II 10

Superconducting UCN polarizer 3 He circulator 3 He- 4 He heat Peripherals exchanger Isopure 4 He GM cryostats and circulator He recovery line

Heat load from outside to the horizontal UCN guide and the UCN extraction part, was 1 W 0.3 W 0.2 W Added 4K radiation shield 40K radiation shield SCM for UCN Heat extraction exchanger B 0 He-II Replaced Be-Cu with stainless steel for better thermal insulation

Increasing UCN production rate from 4 to 200 UCN/cm 3 /s at E c = 210 neV 3 He pumping of 2000 m 3 /h 10000 m 3 /h for 5W (10 W) E p × I p = 20 kW 3 He cryostat We have achieved cooling power of 1 W at 0.7 K (2 W at 0.8 K) UCN source E p × I p = 4 kW (8 kW) Heat load on He-II 1 W 0.3 W 0.2 W 3 He evaporation 32 × 10 -3 mol/s 9.6 × 10 -3 mol/s 6.4 × 10 -3 mol/s He-II temperature 0.7 K 0.6 K 0.58 K Superconducting magnet 13

Isopure 4 He Tube Pulse 3 He 4He pumping UCN production and polarized UCN extraction 3 He cryostat pumping UCN source 3 He GM cryostat Liq.He 1K pot SCM polarizer 8L pot 20K D 2 O 10K D 2 O He-II Spin flipper UCN 300K D 2 O UCN double Spin valve Target valve analyzer Graphite Concrete Steel UCN detector 14

UCN production Preliminary 3 He cryostat Superconducting UCN polarizer UCN polarization to be published UCN guide Preliminary UCN spin flipper analyzer Effect of holding field UCN detector 15

UCN storage lifetime in He-II SCM V F (guide) B 0 = 210 neV Vacuum He-II Al foils UCN was counted Including Al foils as a function of valve opening time B 0 = 0 → 3.5 T τ = 20 → 40 s Preliminary Preliminary τ = 9 s UCN transmission is enhanced ! He-II UCN valve is effective ! μ B 0 (3.5T) = 210 neV, V F (Al) = 54 neV. 16

Increasing UCN storage lifetime to 100 s He-II 3 He absorption: τ 3He = 3900 s at 3 He/ 4 He = 10 -11 Wall loss loss/collision: μ = 2 f ∫ { E cos 2 θ /( V - E cos 2 θ )} 1/2 cos θ d(cos θ ) V f = W / V E < V optical potential U = V - i W = 2 π h 2 / m N ( a r - i a i ) Im f (0) = k /4 π σ tot σ tot = σ inela + σ a We need material of low absorption and high Fermi potential

Suitable wall material for τ > 100 s We need material of lower f = W / V ! The material should sustain at the low temperature ! → 58 Ni → Be pipe or DLC coating? NiP electropolished electropolished SUS316L R a < 2 nm aluminum He-II UCN valve In future, Be pipe or DLC coating? 58 Ni coated pipe good heat conduction

Pulse Isopure Tube 3 He 4He pumping 4 He nEDM, KEK-Osaka-RCNP 3. nEDM with 129 Xe co-magnetometer 3 He cryostat H.V. pumping EDM 1. He-II UCN production cell in spallation source 3 He Liq.He Door valve 1K pot SCM 8L pot Rotary 20K D 2 O 10K D 2 O valve He-II Spin flipper 2. Magnetic Spin Target analyzer extraction of UCN Graphite Steel Concrete from He-II UCN detector 19

nEDM apparatus connected to the UCN source Permalloy shield 3 He cryostat Compensation coils Spallation UCN source Superconducting Ramsey resonance UCN polarizer apparatus

Ramsey resonance apparatus Spherical coil for B 0 Old source EDM cell π /2 RF coil Door valve UCN valve Spin flipper Iron magnetized foil Rotary valve UCN detector 21

Ramsey resonance nEDM is measured from shift upon E reversal B 0 stability ��� � ( ω - ω o )t c = - π π -5 π 3 π 5 π ������������������������� � ������������������������ µ � � -3 π ��� � ��� � ��� � measured by old source -4 π 4 π -2 π 0 2 π � � ��� � ��� � ��� � ��� � ��� � �������������� � 200 mG 22

μ B 0 monitor: 129 Xe spin precession 129 Xe level scheme B o P 129Xe = λ = 252 nm 3 mmTorr 5 p 5 ( 2 P 3/2 )6 p ( 2 [3/2] 2 ) δν < 1 GHz P > 0.5 W +3/2 F =3/2 EDM cell 2 Beam size GHz +5/2 +3/2 F =5/2 < 50 μ m 129 Xe σ + 895.5 photon 823.4 nm nm detector 5 p 5 ( 2 P 3/2 )6 s ( 2 [3/2] 1 ) 5 p 5 ( 2 P 3/2 )6 s ( 2 [3/2] 2 ) x8 IR photons 252.5 nm × 2 5 days of δ M F = +2 measurement δ B 0 = 0.3 fT 5 p 6 ( 1 S 0 )6 s t 10 -27 e cm F =1/2 -1/2 +1/2 M. Mihara T. Chupp 23

Rb-Xe spin exchange optical pumping Happer B 0 solenoid coil We have achieved 129 Xe polarization of 70% B 1 ( ν = 51.5 kHz) enriched Xe 0.3 Xe 10 Torr ( 129 Xe 86%) N 2 750 Torr Lock-in out (V) 156 °C 0.2 B 0 = 4.3 mT natural Xe ( 129 Xe 26.4%) 0.1 141 °C 0.0 pickup coil σ + B 0 -0.1 0 1 2 3 4 5 t (s) B 1 coil

needle 4He pumping valves We are remodeling cryostat for safety 10 4 m 3 /h pump 3 He reserver He venting upon vacuum failure 3 He Present helium venting tube PulseTube pumping complies with ASME Isopure 4 He at normal vacuum loss. 3 He For sudden huge vacuum Liq.He loss, we are now working on 1K reconstructing the cryostat. pot 3 He- 4 He 8L heat pot 20K D 2 O 10K D 2 O exchanger He-II Target

Our nEDM Statistical error: 10 -27 ~10 -28 e cm 1. He-II UCN production in spallation n source P = 4 UCN/cm 3 · s at E c = 210 neV, E p × I p = 0.4 kW (2012) → 200 UCN/cm 3 · s in 12 L He-II 20 kW τ s = 81 s (2012) → 100 s ρ pol = 800 UCN/cm 3 in the EDM cell of E c = 90 neV 2. Magnetic extraction of UCN from He-II P UCN = 90% at the EDM cell visibility α = 83 % Systematic error: 10 -27 e cm 3. 129 Xe co-magnetometer

Thanks

Recommend

More recommend