18 TH INTERNATIONAL CONFERENCE ONCOMPOSITEMATERIALS MULTISCALE MODELLING OF POLYMER-CLAY NANOCOMPOSITES Y. Chen 1 , Y.H.Chia 2 , T.E. Tay 1 , V.B.C.Tan 1 * 1 Department of Mechanical Engineering, National University of Singapore, Singapore 2 Institute of Material Research and Engineering, A*STAR, 3 Research, Link, Singapore * Corresponding author (mpetanbc@nus.edu.sg) Keywords : multiscale modeling, nanocomposites, representative volume element, periodic boundary conditions, cohesive zone model 1Introduction 2.2.1 Polymer Matrix Polymer-clay nanocomposites is a subject of For the matrix, the thermoplastic Nylon6 is growing interest as they often exhibit markedly investigated, and the chain length is set to be 20 due improved material properties compared to the pure to the computational limit of classical molecular polymer matrix or traditional micro/macro simulation. A cubic cell packed with Nylon6 chains composites. However, these novel materials also is built and loaded in uni-axial tension to explore the bring about challenges in the prediction of their elastic-plastic properties of the pure matrix. properties. Simulations using classical molecular Table 1. Elastic constants of Nylon6 dynamics (MD) are normally limited to a few billions of atoms while traditional continuum Young’ modulus 3.3 Gpa mechanics and composite theories are unable to Possion’s ratio 0.35 include the atomistic characteristics of the nanoscale The plastic regime of the stress-strain relationship interfaces; an important feature in nanocomposites was also obtained but is not shown here. because of the high surface-to-volume ratios 2.2.2 Clay and Cohesive Zone Model (CZM) involved. In this study, a multiscale modeling approach of polymer-clay nanocomposites is The intercalated clays have a layered structure, presented. The mechanical properties of the matrix, composed of inorganic silicate sheets and organic clay particles and interfaces are obtained from MD galleries between them. It has been experimentally simulations which are then imported into a observed that the interlayer failure of organic representative volume element (RVE) modeled galleries would lead to the formation of the using the finite element method (FEM). Hydrostatic microcracks which are able to propagate along the tension is conducted on the RVE cell to investigate silicate surface and then into the matrix, leading to the influence of splitting failure within intercalated final failure of the macroscale samples [1, 2]. In clays on the mechanical performance of the bulk order to understand the influence of the gallery materials. failure on the mechanical performance of the bulk system, the clay particles are modeled as a disc-like 2Models and Methodology sandwich [3], comprising two stiff and isotropic effective layers with a cohesive layer [4] in the 2.1 Material System middle representing the organic gallery as illustrated The computational model is based on an actual in Figure 1. The isotropic layers and cohesive layer nanocomposite system. The polymeric matrix being are also fully parameterized by MD simulations studied is Nylon6. The clay particles specified in the using the modified PCFF force field [5]. study is organic modified montmorillonite (OMMT) with cations exchange capacity (CEC) of 90 2.3 Finite Element Model mequiv/100mg and it closely represents the product from the Southern Clay Company, US. 2.3.1 Geometric Features A RVE cell of polymer-clay nanocomposite at the 2.2Molecular Dynamics Model mesoscale level is introduced to study the failure

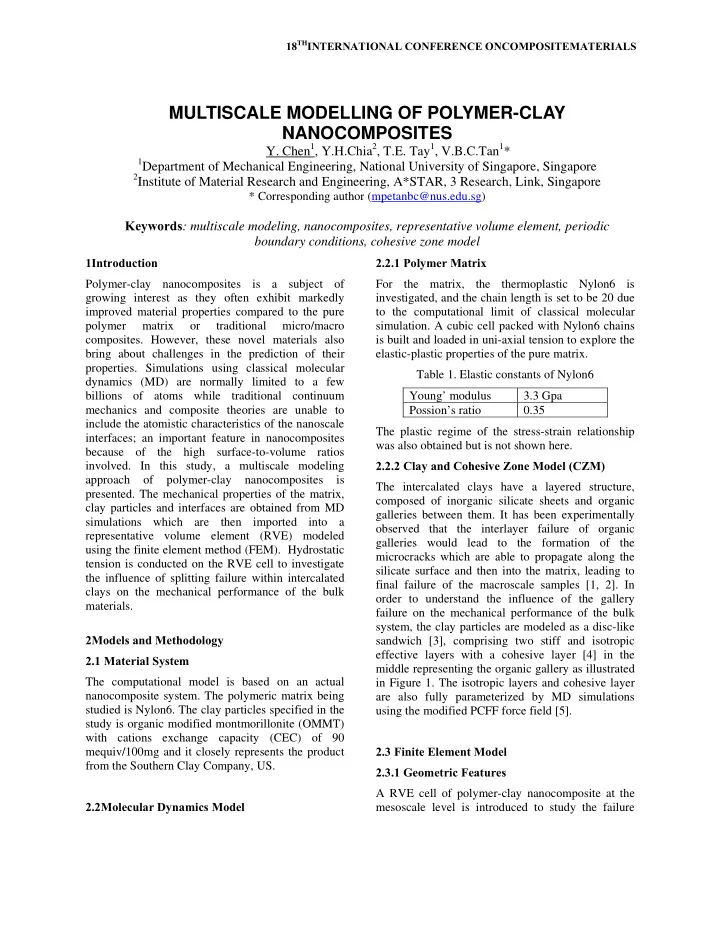

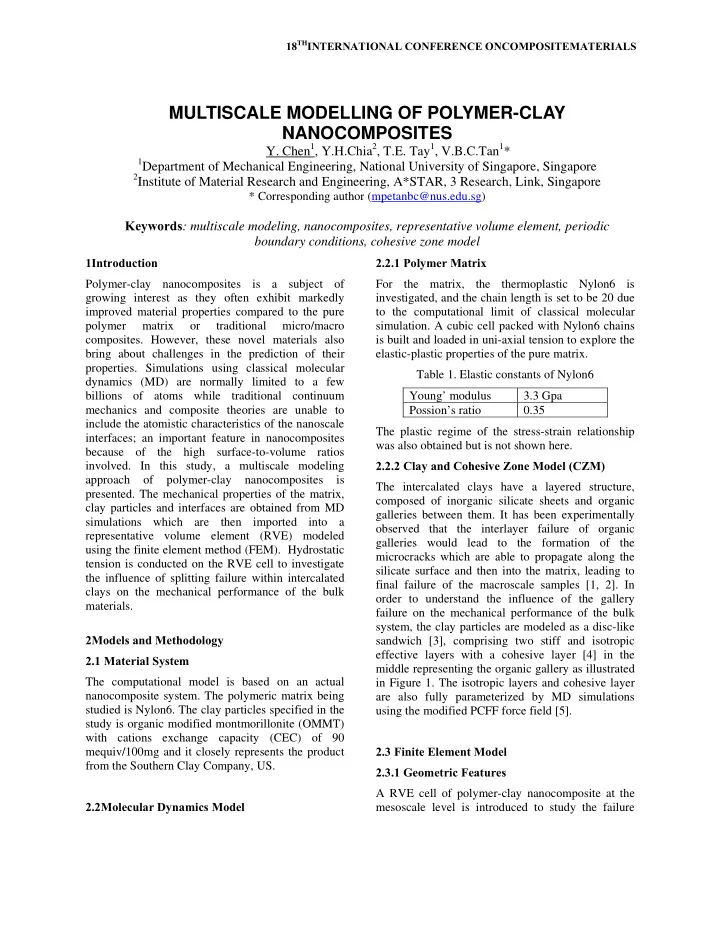

mechanism of the hybrid system. It is assumed that failure process from the splitting damage of the the intercalated clay particles are randomly intercalated clay particles. distributed throughout the matrix, and they follow the periodic distribution on the boundary surface as Front Back Difference in illustrated in Figure 2(a). stress contours σ T Γ δ No- Splitting damage PBC Fig.1. (a) Experimental observation of the formation of microcracks in layered clay particles, (b) Cohesive zone model of layered clays with molecular details, (c) Traction-separation law to describe the splitting failure of the gallery. Back Front Similarity in stress contours (a) (b) Gallery failure Fig.2. (a) Geometric periodic distribution of clay particles, (b) Periodic boundary condition constrain on the surface nodes of the RVE cell. 2.3.2 Periodic Boundary Condition PBC Splitting damage Periodic Boundary Conditions (PBC) are imposed on the surface nodes to ensure the continuity of stress contours and synchronous splitting failure on opposite surfaces of RVE, as shown in Figure 2 (b). Figure 3 shows the comparison of stress contours and splitting failure of two opposite surfaces with two different boundary conditions. 2.3.3 Loading condition Fig.3. Comparison of stress contours and particle Hydrostatic loading is applied on the RVE cell. The splitting of two opposite surfaces with and without PBC. mean stress , volumetric strain of the RVE domain and the scalar stiffness degradation (SDEG) of the cohesive elements of the galleries are recorded to study the 2

3 Results and discussions 3.1 Softening of galleries The splitting of the clay particles coincides with the transition to non-linearity in all curves. It has been Figure 4 shows the comparison of mean stress vs. reported that during the transition, microcracks volumetric strain curves of models with different caused by the splitting failure will quickly propagate softening characteristics of the cohesive gallery, into the matrix, leading to the total failure of the including linear, exponential degradation and tabular bulk material [1, 2]. form from MD results. For all three cases, the mean stresses first increase linearly before any splitting It is found that the strain at which the transition failure of the clay particles. occurs is very sensitive to the softening characteristics of the cohesive gallery. Specifically, 600 1.0 the exponential degradation would lead to a delay of the transition range and the corresponding failure SDEG of damaged clay particles 500 0.8 stress is thus highest, while the linear degradation Mean stress (Mpa) 400 would result in earlier failure of the cohesive gallery 0.6 and give a low failure stress threshold. The MD 300 fitted tabular form gave a failure stress that is 0.4 slightly higher than the linear softening gallery. 200 From the comparison, it is suggests that accurate 0.2 Softening curve: 100 representation of the softening characteristics of the Linear cohesive gallery is essential for predicting the 0 0.0 mechanical behavior of nanocomposite materials, 0.00 0.05 0.10 0.15 0.20 Volumetric strain and hence relevant interfaces should be investigated 600 at the molecular scale in order to accurately predict 1.0 the mechanical performance of the hybrid system. SDEG of damaged clay particles 500 0.8 Mean stress (Mpa) 400 3.1 Clay particle size 0.6 300 The influence of particle size on the mechanical 0.4 200 behavior of the RVE cell is also investigated. Figure 5 shows the stress-strain curves of models with 0.2 Softening curve: 100 different clay size under the same volume fraction of Exponential 4%. It is seen that larger particles would bring about 0 0.0 0.00 0.05 0.10 0.15 0.20 slightly higher reinforcement efficiency in terms of Volumetric strain elastic stiffness because of the increase of the aspect 600 1.0 ratio (diameter/thickness). However, it is also found SDEG of damaged clay particles the splitting failure occurs earlier for large clay 500 0.8 particles and the corresponding failure stress Mean stress (Mpa) 400 threshold is also slightly decreased. 0.6 300 0.4 200 0.2 Softening curve: 100 MD results fitting 0 0.0 0.00 0.05 0.10 0.15 0.20 Volumetric strain Fig.4. Mean stress of RVE cell and SDEG of damaged clay particles with different traction- separation for the cohesive elements. 3

Recommend

More recommend