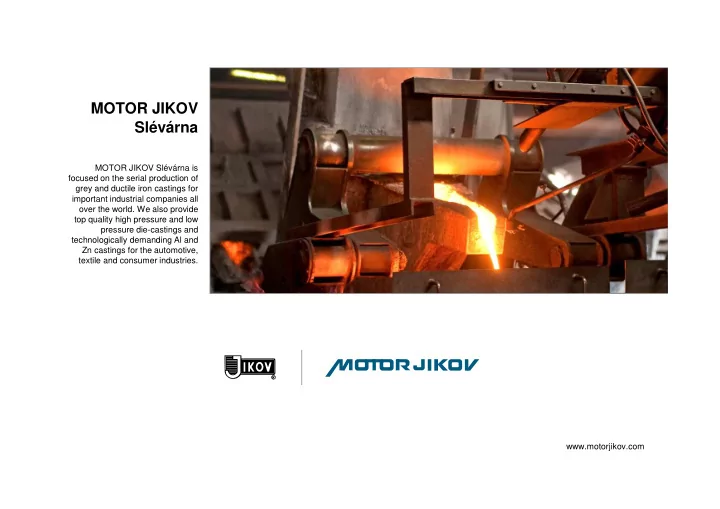

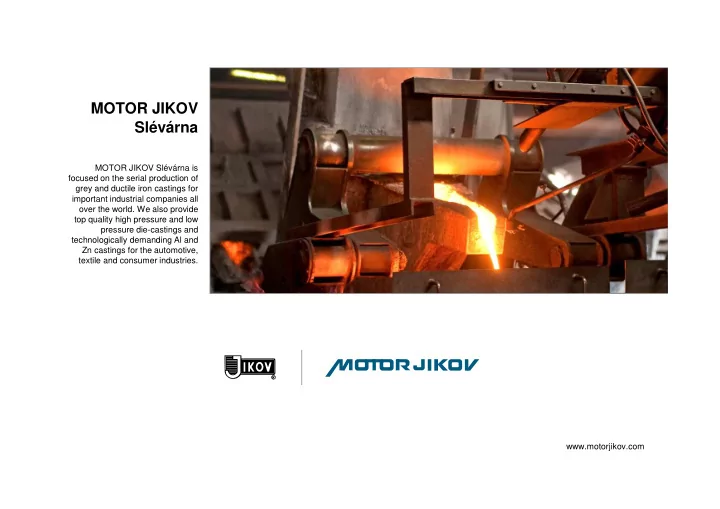

MOTOR JIKOV Slévárna MOTOR JIKOV Slévárna is focused on the serial production of grey and ductile iron castings for important industrial companies all over the world. We also provide top quality high pressure and low pressure die-castings and technologically demanding Al and Zn castings for the automotive, textile and consumer industries. www.motorjikov.com

www.motorjikov.com ORGANISATIONAL Production STRUCTURE Technical Department Ivan Hotový Iron Foundry Division Tomáš Vít ů Sale Gabriela Ciglerová MOTOR JIKOV Slévárna Quality Pavel Č ížek MOTOR JIKOV Slévárna Purchase Kate ř ina Schwarzová Production Martin Babický Die-casting Division Roman Pospíšil Technical Department Roman Pospíšil Sale Kate ř ina Schwarzová

www.motorjikov.com PRODUCTION AND BUSINESS STRATEGIES

www.motorjikov.com CZECH REPUBLIC MOTOR JIKOV Slévárna a.s. Kn ě žskodvorská 2277/26 370 04 Č eské Bud ě jovice Czech Republic www.motorjikov.com Iron Foundry Division T: +420 389 016 485 F: +420 389 016 484 poptavky@mjsl.cz Die-casting Division T: +420 389 016 414 F: +420 389 016 446 info@mjsl.cz

www.motorjikov.com OUR PARTNERS

IRON FOUNDRY DIVISION www.motorjikov.com

www.motorjikov.com MAIN ECONOMIC INDICATORS Iron Foundry Division

www.motorjikov.com TOP CUSTOMERS 2017 Iron Foundry Division

www.motorjikov.com SALES BY TERRITORIES Iron Foundry Division Sales in 2017 EUR 9,2 mil.

www.motorjikov.com SHARE DUCTILE/GREY IRON 2017 Iron Foundry Division

www.motorjikov.com SALES BY INDUSTRY Iron Foundry Division Sales in 2017 EUR 9,2 mil.

www.motorjikov.com IRON Melting/ Melting shop Two EGES 3 MW medium frequency induction MELT & HOLD melting furnaces FOUNDRY (volume 2 x 4 tons, melting output of 6.1 tons per hour). DIVISION Material charging is secured using a vibration cart common for both furnaces. Moulding Frameless moulding line DISAMATIC 2013 LP/PLC-B, vertical parting line, with sizes of sand moulds ranging from 535 x 650 x 120–360 mm. Technology Technical capacity of up to 300 moulds per hour based on the type of casting and presence of cores; sand mixture is prepared in 2 mixers with a capacity of 1–1.2 tons using reversible sand cooling. DISA DTC-2 blasting machine with polygonal drum. Production of cores 4 “Schalco“ (hot box) machines; we purchase the core mixture.

www.motorjikov.com IRON Cast materials FOUNDRY EN GJL 150, EN GJL 200, EN GJL 250, EN GJL 300 EN GJS 400-12, EN GJS 500-7, EN GJS 600-3, EN GJS 700-2 DIVISION Optimum weight of castings is 0.5 – 20 kg. Maximum casting size is limited by mould dimensions Technical specifications for cooperation Technology Data processing: 3D documentation. Pattern shop: drawing documentation, production of epoxy and metal patterns (core boxes) based on the provided standard or 3D data. Pattern production: mostly outsourced; MOTOR JIKOV Slévárna takes care of the layout and gating system, while the inlet simulation is outsourced if required.

www.motorjikov.com Machinery Equipment IRON FOUNDRY DIVISION Multipurpose SOLO line with protective atmosphere Batch dimensions: 400 x 400 x 600 mm, weight max.110 kg Trolley baking chamber furnace annealing (without protective atmosphere) Trolley dimensions: 1700 x 880 x 850 mm, weight 1000 kg induction hardening Heat-treatment shop Heat treatment technology Soft annealing Stress relief annealing Hardening to 930C Tempering Cementing to 1,4mm Nitrocementing VF hardening to a diameter of 55mm Quality Assurance Checking surface hardness, hardness during grinding, the depth of hardened layer in the laboratory. Possibility of issuing certification number Č SN EN ISO 10204

www.motorjikov.com IRON Quality control of material according to the process flow. FOUNDRY An optical emission spectrometer Q4 TASSMAN from Bruker-Elemental is used directly at the smelting furnace where chemical analysis of each smelting process is DIVISION carried out. Samples are subsequently taken from each smelting procedure according to internal procedures or according to customer requirements, where sampling castings are tested in the laboratory for metallurgical and mechanical properties. Capabilities and laboratory equipment Quality Chemical analysis: optical emission spectrometer SPECTROMAX, SPECTRO A.I. Kleve. Metallographic examination / macrostructure and microstructure of the material: grinding preparation for the semi-automatic Buehler grinder/polisher. Inverted metallographic microscope NIKON ECLIPSE MA100 (50x – 500x), NEOPHOT 32, Carl Zeiss (50x – 1000x). Possibility of evaluating the structure using image analysis with NIS-Eements. Mechanical tests: Hardness test according to BRINELL, ROCKWELL, WICKERS hardness tester KB Prüftechnik / 4,903 -2451 N hardness tester BRINELL WPM Leipzig / 7355 N hardness tester ROCKWELL Škoda Plze ň / 98,7 N - 1839 N hardness tester WICKERS ZWICK / 1,961 N - 98,07 N Tension test: pulling machine EDZ 20, VEB WPM Leipzig. / 200 kN.

www.motorjikov.com IRON FOUNDRY DIVISION Certification The companies are certified according to internationally accepted standards by TÜV NORD CERT GmbH. ISO/TS 16949:2009 EN ISO 9001 : 2008

www.motorjikov.com IRON FOUNDRY DIVISION The Iron Foundry is equipped to produce castings weighing from 0.5 to 20 kg Portfolio of castings Portfolio of castings Gearbox hubs Golf cart axle elements

www.motorjikov.com IRON FOUNDRY DIVISION The Iron Foundry is equipped to produce castings weighing from 0.5 to 20 kg Cardan Hub bearing housing Axle components Fender holders

DIE-CASTING DIVISION www.motorjikov.com

www.motorjikov.com MAIN ECONOMIC INDICATORS Die-Casting Division

www.motorjikov.com SALES BY INDUSTRY Die-Casting Division Sales in 2016 EUR 19.2 mil.

www.motorjikov.com DIE-CASTING Al die-casting DIVISION High-pressure die-casting machinery 1x Bühler B 320, 1x Bühler SD/42C 2x COLOSIO PFO 560 2x Bühler SC 66 1x Müller Weingarten 1000 1x COLOSIO PFO 1000 Technology Low-pressure die-casting machinery 1x KURTZ AL16-12SR 2x LPM BPS800-SX Zn die-casting High-pressure die-casting machinery 1x Frech DAW 20t 1x Frech DAW 80t 1x Frech DAW 125t 1x Frech DAW 160t 1x Frech DAW 315t CNC machining - CHIRON FZ08 W, FZ12 W, FZ15 W, DZ15 W Silicone sealing application – specialised automated work place Assemblies and testing – assemblies, leak tests, function tests Heat treatment - Realistic continuous hardening and tempering line for T4-T6 heat treatment.

www.motorjikov.com Aluminium and Zinc high pressure die-casting Al castings up to the weight of 7 kg and Zn castings up to the weight of 3.5 kg, max. tooling dimensions 1600 x DIE-CASTING 1200 x 1000 mm DIVISION Machined materials Aluminium alloys Al 226 (EN 1706 EN AC-46000, DIN 1725-226 AlSi9Cu3, AA A380.0, JIS H 5302 ADC12) Al 231 (EN 1706 AC-47100, DIN 1725-231 AlSi12Cu1, JIS H 5302 ADC1C) Technology Zinc alloys Z410 (EN 12844 ZPO410, DIN 1743-2 Z410 (ZnAl4Cu1)), Z430 (EN 12844 ZPO430, DIN 1743-2 Z430 (ZnAl4Cu3)) TVC – technological Finishing and following processing development centre trimming using hydraulic presses 3 - 28 t, vibration tumbling using Rösler machinery, blasting using Development of technological SCHLICK shot blast machine, suspension blasting, heat treatment procedures and automated workplace concepts for the production of high- Quality control pressure aluminium castings with IMPACT 3D measuring device (450 x 550 x 350), automatic operation and minimum Wenzel 3D measuring device (800 x 1 500 x 700), production times. SEIFERT 225 Kv X-ray, MITUTOYO CV 500 profile meter, SPECTROMAX quantometer, NEOPHOT 32 microscope Cooperation galvanisation and painting, impregnation, thermal pointing, production of tooling, trimming equipment, machining and assembly fixtures, production of special equipment and single-purpose machinery

www.motorjikov.com DIE-CASTING Al low-pressure die-casting DIVISION Castings from 0.1 to 20 kg, max. dimension of ingot moulds 1600x1200x1000 mm Furnace volume max. 800 kg Average time of casting cycle 4-6 minutes Material Low-pressure Aluminium Currently used: die-casting EN AB 42100 - AlSi7Mg0.3 Production possibilities For new projects we can process: Silumin – aluminium and silicon alloys (AlSi, AlSi7Mg, AlSi10Mg) Aluminium and copper alloys (AlSi9Cu) Low-pressure die-casting machine KURTZ AL16-12SR 2x LPM BPS800-SX Heat treatment The Realistic continuous hardening and tempering line for T4-T6 heat treatment.

www.motorjikov.com DIE-CASTING DIVISION Certification The companies are certified according to internationally accepted standards by TÜV NORD CERT GmbH. EN ISO 9001 : 2008 EN ISO 14001 : 2004 ISO/TS 16949 : 2009

www.motorjikov.com DIE-CASTING DIVISION The essential part of production is intended for the international automotive and consumer industries. Cylinder H560 Flange assembly Gearbox cover Crankshaft holder

www.motorjikov.com DIE-CASTING DIVISION Low pressure die-casting Production is intended for international automotive industry. Spacer for truck tanks Spacer for truck tanks Stroke cylinder Support arm

Recommend

More recommend