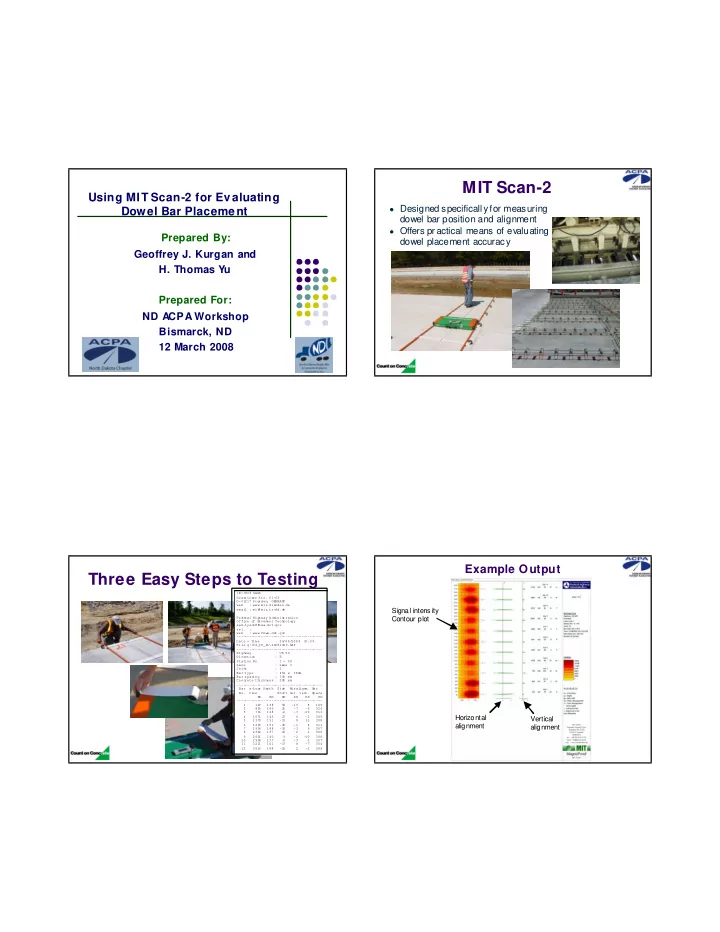

MIT Scan-2 Using MIT Scan-2 for Evaluating Designed specificall yfor measuring Dowel Bar Placeme nt dowel bar position and alignment Offers pr actical means of evaluating Prepared By: dowel placement accuracy Geoffrey J. Kurgan and H. Thomas Yu Prepared For: ND A CPA Workshop Bismarck, ND 12 March 2008 Example Output Three Easy Steps to Testing (R) MIT Gmb H Gost ritz er Str. 61- 63 D-01 217 Dre sden , GE RMAN Y web : www .mit -dre sden .de Signal intens ity emai l : mit @mit .tz- dd.d e Contour plot Fede ral Hig hway Adm inis trat ion Offi ce o f P avem ent Tech nolo gy sam. tyso n@f hwa. dot. gov tel. : web : www .fhw a.do t.go v ---- ---- --- ---- ---- ---- ---- ---- --- ---- ---- Date + T ime : 26 /08/ 2004 1 0:09 File g:\ 04_ 08_2 6\26 0810 09.h df ---- ---- --- ---- ---- ---- ---- ---- --- ---- ---- High way : US 90 Dire ctio n : E Stat ion No. : 1 + 00 Lane : La ne 1 Join t : 1 Bar type : 45 4 x 38m m Bar spac ing : 30 0 mm Conc rete th ickn ess : 28 0 mm ---- ---- --- ---- ---- ---- ---- ---- --- ---- ---- Bar x- Loc a De pth Sid e M isal ign m. B ar No. ti on Shi ft h or. ver t. S pace m m mm m m mm mm mm ---- ---- --- ---- ---- ---- ---- ---- --- ---- ---- 1 12 9 138 5 4 -19 8 129 2 45 5 146 2 5 -7 -6 326 3 76 6 148 - 2 -3 - 10 311 Horizontal 4 107 1 143 2 7 0 -2 305 Vertical 5 137 9 151 -1 3 8 12 308 alignment 6 169 0 151 -3 2 -1 4 311 alignment 7 199 6 148 -1 9 -3 6 307 8 230 2 137 1 0 2 2 305 9 260 1 140 9 -2 - 10 300 10 290 8 137 - 9 -3 0 307 11 321 1 141 -1 7 8 -7 304 12 351 6 144 -2 6 2 -2 304

Dowel Alignment Key Acceptance Items Plan Plan Plan Concrete strength Slab thickness Air content Horizontal Longit udinal Horizontal translation translation skew Initial smoothness Section Section Dowel bar alignment Vertical Vertical translation tilt State Specifications So what if dowels are misaligned? 10 9 Pav ement damage may result Spalling 8 Numberof states 7 Cracking 6 The eff ectiveness of dowel bars may be 5 compromised 4 Loss of load transfer efficiency(LTE) 3 Premature development of faulting 2 How bad is bad? – we don’t know 1 Existi ng specifications maybe too tight 0 5 mm (3/16 in) 6 mm (1 /4 in) 10 mm (3/8 i n ) 13 mm (1/2 in) Comprehensive study under way (NCHRP 10-69) Tolerance on Horizontal or Vertical Misalignement

IN1 – 5 years old Joint Score for IN1 (Basket) 5 0 4 5 4 0 3 5 Joint Score 3 0 2 5 2 0 1 5 1 0 5 0 1 3 5 7 9 1 3 5 7 9 1 3 5 7 9 1 3 5 7 9 1 3 5 7 9 1 1 1 1 1 2 2 2 2 2 3 3 3 3 3 4 4 4 4 4 J oint KS4, NB I-35 – 6 years ol d Joint Score for KS4 (DBI) 5 0 4 5 4 0 3 5 Joint S core 3 0 2 5 2 0 1 5 1 0 5 0 1 3 5 7 9 1 1 1 3 1 5 1 7 1 9 2 1 2 3 2 5 2 7 2 9 3 1 3 3 3 5 3 7 3 9 4 1 4 3 4 5 4 7 4 9 Join t

30- yr old GA section with extremel y poor dowel alignment Joint Score for the GA Section (DBI) 50 45 40 35 Joint Score 30 25 20 15 10 5 0 1 2 3 4 5 6 7 8 9 1 0 1 1 1 2 1 3 1 4 1 5 1 6 1 7 1 8 1 9 2 0 2 1 2 2 2 3 2 4 2 6 2 7 2 8 3 0 3 2 3 3 3 5 3 6 3 7 3 8 3 9 4 0 4 1 4 2 4 3 4 4 4 5 4 6 4 7 4 8 4 9 5 0 Joint Joint Score for the WA Section (Retrofit) 5 0 4 5 4 0 3 5 Joint S core 3 0 2 5 2 0 1 5 1 0 5 0 1 3 5 7 9 1 1 1 3 1 5 1 7 1 9 2 1 2 3 2 5 2 7 2 9 3 1 3 3 3 5 3 7 3 9 4 1 4 3 4 5 4 7 4 9 Join t

WA section – 35 yr old pavement; 8 yr old retrofit Effects of Embedment Length ( Burnham 1999 ) Effects of Dowel Misalignment Comparison of DBI and Basket (Prabhu et al. 2006) 10 0% Bas ket 9 0% DBI 78.8% 8 0% 72.7% 7 0% ent of bars 6 0% 5 0% Perc 4 0% More critical ranges of misalignment 3 0% 1 9.2% 2 0% 14. 2% 1 0% 5.7% 3.6% 1.7% 1.8% 1. 6% 0.6% 0% d ≤ 10 10 <d ≤ 15 15<d ≤ 2 0 20 <d ≤ 25 d >2 5 Range of misalignment,mm

ProblemJoints Typical Joint

Use of MIT Scan-2 data in optimizing Dowel Placement Specifications PCC mix for dowel-bar inserter (CPTP Techbrief FHWA-HIF-07- 021) 12% Ideally , dowel bars should be placed without any Aug 7 placement error Aug 10 10% Aug 12 There are tolerable lev els of placement errors 8% % of Bars Stringent (but constructible) requirements should 6% be specif ied, but allowance should be made f or tolerable errors 4% 2% 0% 10<d ≤ 15 15<d ≤ 20 20<d ≤ 25 d > 25 Range of misalign ment, mm

Possible Options for Correcting Misaligned Bars Cut misaligned bars Retrof it additional dowel bars Remov e and replace slab Full-depth repair

Best approach: don’t create problems Some misalignments are harmless 5 0 5 0 4 5 4 5 4 0 4 0 3 5 3 5 Joint Score 3 0 Joint Score 3 0 2 5 2 5 2 0 2 0 1 5 1 5 1 0 1 0 5 5 0 0 1 3 5 7 9 1 3 5 7 9 1 3 5 7 9 1 3 5 7 9 1 3 5 7 9 1 2 3 4 5 6 7 8 9 10 1 1 2 1 13 14 1 5 6 1 17 18 9 1 2 0 21 22 23 4 2 25 26 27 8 2 29 30 31 3 2 33 34 35 3 6 37 1 1 1 1 1 2 2 2 2 2 3 3 3 3 3 4 4 4 4 4 Joint J oint

Questions?

Recommend

More recommend