MICROSTRUCTURE AND MECHANICAL PROPERTIES OF EUTECTIC COMPOSITE CERAMIC Al 2 O 3 /ZrO 2 BY EXPLOSION SYNTHESIS Y. Zheng, T. Zhou, G. Ye, X. Zhang Center for Composite Materials, Harbin Institute of technology No.92 West Da-Zhi Street, Harbin, P.R.China Corresponding author (zhengyt@hit.edu.cn) Keywords : Eutectic ceramic, explosion synthesis, combustion synthesis; rapid solidification, in situ composite ) eutectic ceramics had been made on Al 2 O 3 -based Abstract eutectics [5-7], due to the outstanding creep Al 2 O 3 /ZrO 2 eutectic ceramics were prepared by resistance of sapphire along the c-axis. In the last two explosion synthesis using Al and Zr(NO 3 ) 4 as raw decades, as the development of processing of eutectic materials. The Al 2 O 3 /ZrO 2 eutectic microstructure ceramics, there were several preparation techniques showed that the rod-like ZrO 2 phases with a diameter for eutectic ceramics, such as Bridgman method [8], 200 nm were embedded orderly in Al 2 O 3 matrix. laser heated floating zone method [9], micro pulling With the increasing of the reaction temperature, the down method [10], explosion synthesis method and volume content of the Al 2 O 3 /ZrO 2 eutectic increased so on. Explosion synthesis method has some accordingly, and the diameter and phase spacing of particular advantages compared with other methods. rod-like ZrO 2 decreased, which was mainly attributed The preparation procedure of explosion synthesis is to the efficient diffusion and the large temperature very simple. Also, it is an energy saving method gradient. Due to the fine structure of the Al 2 O 3 /ZrO 2 because the materials can be heated by the energy eutectic, the Vickers hardness and fracture toughness released from the reaction without any other addition can reach 21GPa and 11.7 MPa·m 1/2 , respectively. thermal resource. Furthermore explosion synthesis method can prepare bulk samples of large size. 1. Introduction In this paper, Al 2 O 3 /ZrO 2 eutectic ceramic was Ceramic matrix composites offer improved toughness product by explosion synthesis method, and the and strength compared with monolithic ceramics due relationship between the temperature and the to the dispersion of energy of cracks at the interface microstructure was discussed. of the two phases [1]. Eutectic ceramics with a fine 2. Experimental procedure microstructure on micrometer or nanometer scale are a paradigm of in situ ceramic matrix composites [2], The reactant powders were Al and Zr(NO 3 ) 4 powders. which have outstanding thermal stability and The explosion reaction for preparing eutectic ceramic mechanical properties as compared with monolithic was listed as follow: and conventional ceramic matrix composites [3]. The → Al 2 O 3 +ZrO 2 +N 2 Al+ Zr(NO 3 ) 4 (1) mechanical properties of two phase eutectic ceramics are better than that of either constituent alone, Through adding appropriate Al 2 O 3 and ZrO 2 into because of the strong constraining effects provided reactant, the reaction temperature and Al 2 O 3 /ZrO 2 by the interlocking microstructure [4]. ratio in products can be adjusted. The raw materials In the past, attention focused on metallic eutectics were mixed by ball milling for 12 h using alumina was more than eutectic ceramics, and most of the milling-media. advances of eutectic growth and microstructure were In order to rapid solidification of melted Al 2 O 3 and achieved in metallic eutectics. This was because that ZrO 2 , the explosion synthesis took placed in a high the eutectic temperature of eutectic ceramics is higher pressure reactor with water cooling system, with an than that of metallic eutectics and the preparation of inside diameter of 25 mm. The gas pressure in the eutectic ceramics was difficult. Most efforts of

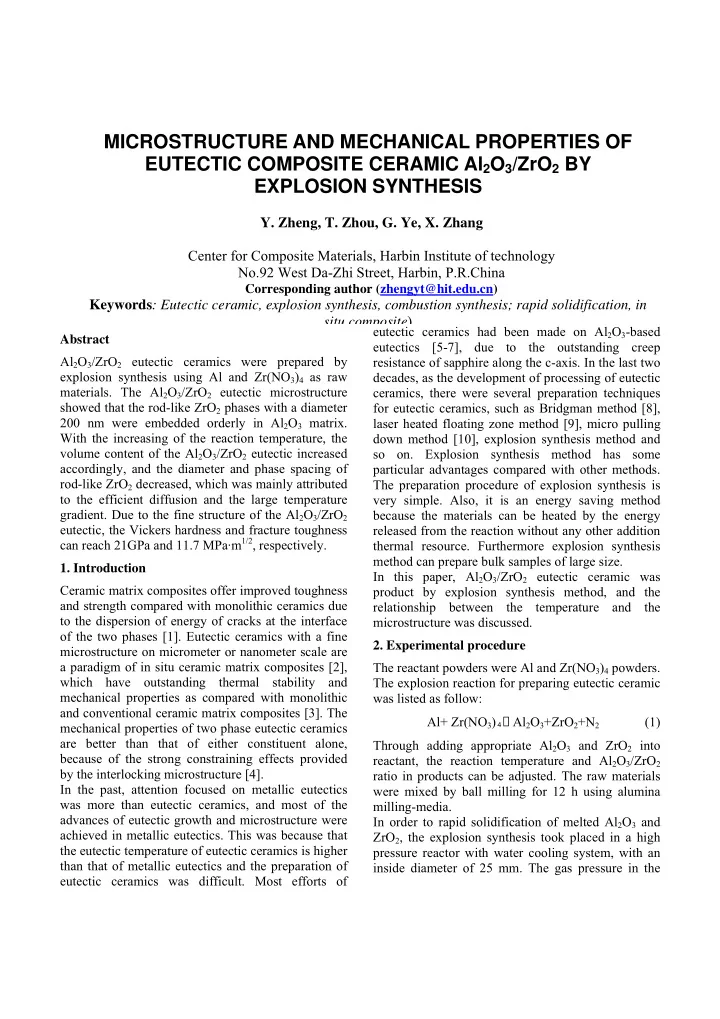

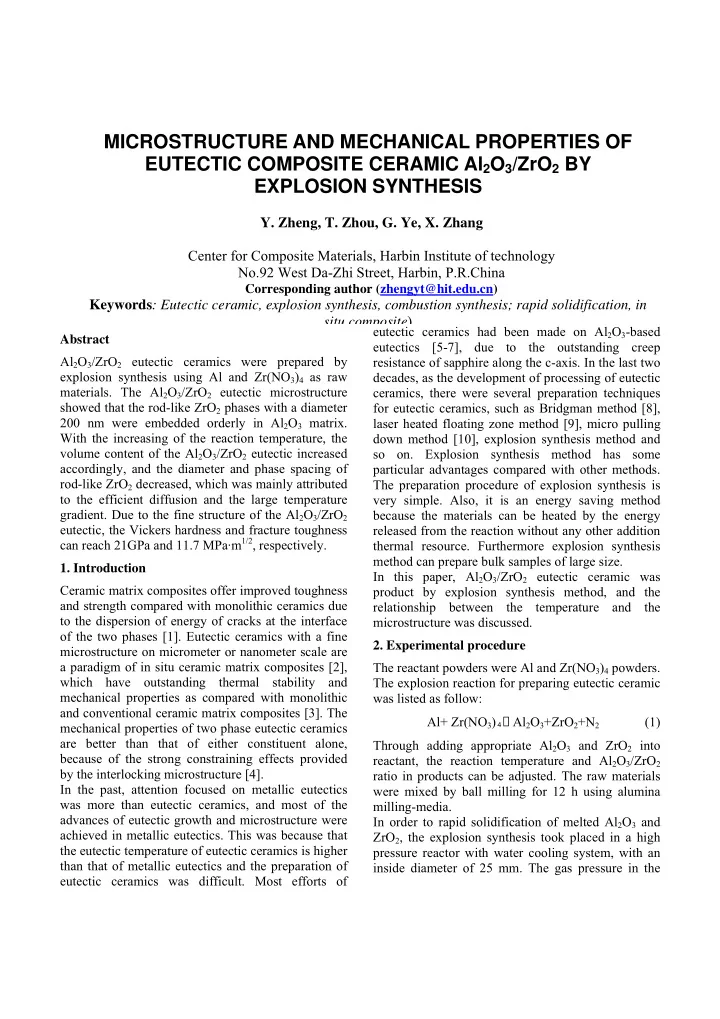

reactor ranges from 30 MPa to 100 MPa. The According the reaction (1), the pressure in the reactor reaction temperature was measured by W/Re produced by the released nitrogen gas and thermocouples (2100-2600 K). evaporation of Al 2 O 3 and ZrO 2 was calculated The morphology of the cross-sections of the theoretically based on Van der Waals equation. Fig. 2 shows the relationship between the reaction products was examined by scanning electron temperature and the pressure in the reactor. It can be microscopy at 20 kV using a FEI Quanta 2000F. found that the pressure in reactor increased with the Energy dispersive X-ray spectroscopy (EDS) increasing reaction temperature. A suddenly rising in was used to elemental and microstructure pressure occurred at eutectic temperature of 2135 K analysis. because of the phase state change in reactant system. In addition, a more dramatic increasing occurred at 3. Results and discussion the boiling point of Al 2 O 3 and ZrO 2 (at temperature Because the explosion synthesis of the Al 2 O 3 /ZrO 2 of about 4500 K). In this experiment, nitrogen eutectic ceramic was completed instantly, the pressure under 100 MPa was adopted to ensure the reaction can be regarded as an adiabatic procedure. reactor safety and economical benefit. The adiabatic temperature was calculated through thermodynamics analysis, as shown in Fig. 1. It indicated that the adiabatic temperature increased 350 linearly with increasing Al content, and a temperature 300 platform occurred at the Al 2 O 3 /ZrO 2 eutectic 250 pressure (MPa) transformation temperature (2135 K). To obtain Al 2 O 3 /ZrO 2 eutectic ceramics, the reaction 200 temperature of the explosion synthesis should be 150 higher than the eutectic transformation temperature. The reactant components with adiabatic temperature 100 of 2300, 2500, 2700 and 2900 K were selected to 50 study the reaction temperature on the morphology 0 and microstructure of the Al 2 O 3 /ZrO 2 eutectic. 1500 2000 2500 3000 3500 4000 4500 5000 5500 Tad (K) Fig. 2. The relationship between reaction temperature and pressure. 3500 The reaction temperature was measured by W/Re 3000 thermocouples (2100-2600K), as shown in Fig. 3. As the figure indicated, explosive reaction has very Tad ( K) quickly reaction velocity, and temperature rising and 2500 cooling of the samples were relative sharp, which is benefit for the formation of eutectics with fine 2000 structure. Due to the secondary exothermic of the hypereutectic, a slight temperature increasing was 1500 found during the cooling stage of the reaction. The 8 10 12 14 16 formation enthalpy of Zr(NO 3 ) 4 , which can not be Proportion of Al (%) inquired in thermodynamics manuals, was calculated Fig. 1. Relationship between the T ad and Al content. by fitting method based on the measured reaction In the sealed reactor, large content of nitrogen was temperature ( ∆ H =2.9kJ/mol). released and produced high pressure during the explosion synthesis under high temperature in a short time, and the high pressure will increase the boiling point of Al 2 O 3 and ZrO 2 . Choosing proper reactant ratio of the Al to ZrO 2 can assure the appropriate reaction temperature to melt Al 2 O 3 /ZrO 2 eutectic.

Recommend

More recommend