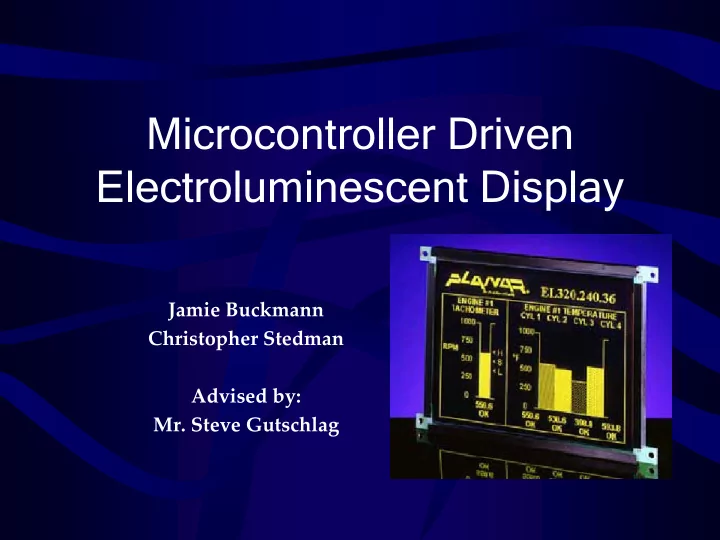

Microcontroller Driven Electroluminescent Display Jamie Buckmann Christopher Stedman Advised by: Mr. Steve Gutschlag

Outline – Project Summary – Functional Description – System Block Diagrams – Software – Completed Tasked – Results – Future Work

Project Summary Mechanical Engineering department requested that a multifunctional display be designed for the SAE formula car.

Functional Description Oil Pressure Neutral Coolant Microcontroller Temperature Driven Electroluminescent Display Data O 2 Sensor Electroluminescent Keypad Display Ignition Signal Front Tire Sensor

Ignition Sensor (RPMs)

Front Tire Sensor (Speed)

Functional Description OIL COOLANT NEUTRAL

Block Diagram * Ignition Signal OE (RPM) XD0-XD3 Decoding Decoding Logic A0 ALE Front Tire Electroluminescent A 8:15 Logic SED-1330 Ignition Signal Sensor Display (Block 2) LCD Controller START XECL (Block 4) (Block 3) AMD-80C31 A (8:15) LCD Controller Chip Select Oil Pressure Front Tire CLK CS XSCL Microcontroller 80C31 AD & Com From Decoder (Block 1) Data Bus Neutral LP Sensor Address Bus LCD Controller Microcontroller GAL26CV12B +5V Vref+ WF with External (Block 3) AD[0:7] 0V Vref- YDIS RD A/D Chip Select/ Neutral ADC0808 Decoding Program Memory, YD WR RD A0 A A/D Data Bus Control Signals EOC YSCL Data Memory, & HM62256 Interrupt Signal WR A1 B Static RAM (Block 6) Oil Pressure Latch (Block 5) MM74C923 RES to Microprocessor Keypad Chip Select C Keypad A2 Keypad Encoder (Block 1) RD (Block 7) (Block 2) * Decoding Logic WR 10 MHz Clock Signal 500 kHz Square Wave IN[0:7] Conditioned Analog Inputs Port 1 & Port 3 Coolant Analog Signal Conditioning VR/W VCE VA0-VA14 VD0-VD7 Temperature for A/D Signal ADC0808 (Block 8) Conditioned Conditioning Analog Signal O 2 Sensor A/D (Block 8) (Block 6) * Decoding Logic

Timing Write XD0-XD3 A0 XECL CS XSCL From Decoder LP LCD Controller WF (Block 3) AD[0:7] YDIS YD RD YSCL WR RES VR/W VCE VA0-VA14 VD0-VD7

Timing Read XD0-XD3 A0 XECL CS XSCL From Decoder LP LCD Controller WF (Block 3) AD[0:7] YDIS YD RD YSCL WR RES VR/W VCE VA0-VA14 VD0-VD7

Memory Space FFFF A/D C000 Keyboard A000 9FFF LCD Controller 8000 7FFF Program & Memory Space 0000

Start Main Function Flowchart Declare global variables Declare pointers (P1.7) = 0 Screen Initialization: Wait for 5 ms (P1.7) = 1 – 8-pixel character width and height Initialize Screen Set character start address to 0000h – 40 address bytes per line Set graphic start address to 1000h – Height of 240 lines Write spaces to all addresses in character layer – No scrolling Write blanks to all addresses in graphics layer – Layer 1 = Text Mode Display screen – Layer 2 = Graphic Mode End

Tachometer Start Increment (Display value) = FF hex Flowchart (11111111) no ? yes Address = Address +1 F0 Last address in tachometer box Previous address yes ? 78 no (Display value) = 0 F8 Shift (Display value) right (Display value) = (Display value) OR 80h Write (Display value) down 10 times End

Analysis of Results -Designed and built interface between microcontroller and LCD Display -Designed and wrote display software – Original code in assembly – Conversion to C code -3 Screens – Racing Mode – Testing Mode – Time vs O 2 Graph

Race Screen COOLANT GAS OIL GEAR

Test Mode Screen OIL COOLANT NEUTRAL

O 2 Screen O2 time 3.26 4.32 3.54 4.86 4.49

Analysis of Results Developed system that is independent of the MicroPac board -80C31 -27C256 EPROM -HM62256 SRAM -ADC0808 A/D -Attached to Display Controller

Analysis of Results –Keypad –Voltage regulation –Acquired signal parameters from the SAE Team (signal conditioning)

Printed Circuit Board Interconnections Designed in MultiSim 7 Exported to UltiBoard 2001 where chips were arranged on PCB

Printed Circuit Board

Printed Circuit Board

Future Work • Generate more code to display acquired data • Attach system to SAE car • Designed PCB has limitless applications

Recommend

More recommend