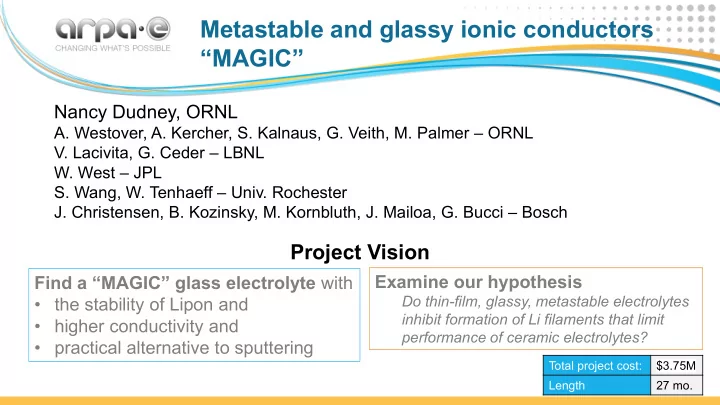

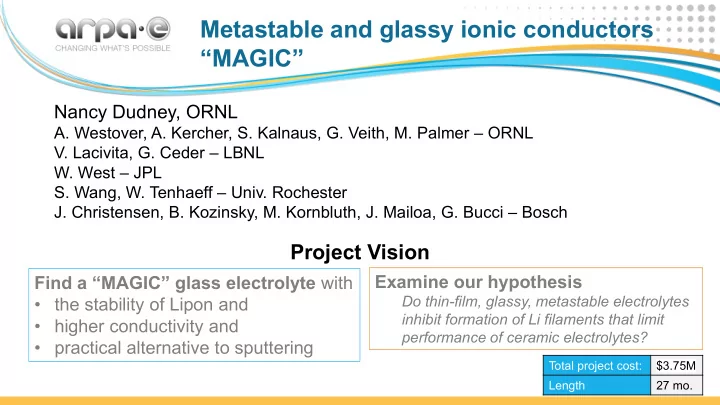

Metastable and glassy ionic conductors “MAGIC” Nancy Dudney, ORNL A. Westover, A. Kercher, S. Kalnaus, G. Veith, M. Palmer – ORNL V. Lacivita, G. Ceder – LBNL W. West – JPL S. Wang, W. Tenhaeff – Univ. Rochester J. Christensen, B. Kozinsky, M. Kornbluth, J. Mailoa, G. Bucci – Bosch Project Vision Examine our hypothesis Find a “MAGIC” glass electrolyte with Do thin-film, glassy, metastable electrolytes • the stability of Lipon and inhibit formation of Li filaments that limit • higher conductivity and performance of ceramic electrolytes? • practical alternative to sputtering Total project cost: $3.75M Length 27 mo.

The Concept ‣ Synthesize a conductive N-stabilized glassy electrolyte as nanopowders Plasma torch glassy Conventional Advanced nano powders sputtered film ~1µm manufacturing of membranes 20µm nucleate Li 3 P O 4 LiSiPON amorphous Si N x “ MAGIC” gas quench S y Support with B polymer mesh also LLZO, LATP Models and films to down select * Handle safely.

The Team Bosch (Cambridge) LBNL Jet Propulsion Lab What compositions What is the role of N? Engineer one-step to remain glassy from a stable Li interface! ORNL melt quench? Make it, test it! Univ. of Rochester Bosch (Sunnyvale) Polymer mesh can How do dendrites support thin glass. form, propagate? 2

Project Objectives 9 th Q end 10 th Q 5 full cells of 5 cm 2 , ‣ 1. MAGIC electrolyte efficient Li cycling, high rate, high capacity 0.3 mAh/cm 2 ‣ 2. Plasma torch processing stable, conductive MAGIC powders 1 mA/cm 2 , 100 cycles ‣ 3. Mechanical properties of MAGIC high K 1C by indentation 30% degrade ‣ 4. Hypothesis test. Will glasses be best at high current? 2 MPa-m 1/2 , K 1c 200 MPa, flex $10/m 2 10 -4 10 Ionic Conductivity (S/cm) -5 10 -6 10 -7 10 1.0 -8 10 -9 10 Li 4 P 2 O 7 full cells -10 10 Li 4 SiO 4 thin films 0.1 Li 2 Si 0.7 P 0.3 O 3 N 0.18 -11 10 Li 2.8 Si 0.7 P 0.3 O 3.2 N 0.22 -12 10 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5 -1 ) 1000/T (K June 7, 2019 MAGIC metastable and glassy ionic conductors IONICS review 2019 Nancy Dudney 3

Results (using sputtered MAGIC thin films) What about Li shorts? MAGIC thin films by Theory of glass sputtering structure and transport No shorts to 10mA/cm 2 Understand structure, and Li + Li dendrites form at artificial mobility boundary, not through Kinetic passivation at Li Edges and grain boundaries non uniform current New targets, – long life, – reproducible, – lower cost JACS 2018 140 11029; Chem Mater, 2018 30, 7077 ACS EnergyLetters, 4 (2019) 651 June 7, 2019 Insert Presentation Name 4

Results (for Induction Plasma Torch prepared MAGIC nanopowders) MAGIC nano-powders and membranes – Theory of melt/quench of glass limited to Si rich, need more N With 525-625 ° C anneal: • Partial crystallization • No loss of N or Li ! 10 -4 Ionic Conductivity (S/cm) 10 -5 800 ° C 10 -6 10 -7 10 -8 350 ° C 10 -9 Li 2 Si 0.7 P 0.3 O 3 N 0.18 cold pressed Structure for 200 atoms, 3x to average Li 2.8 Si 0.7 P 0.3 O 3.2 N 0.22 cold pressed 10 -10 Li 2.8 Si 0.7 P 0.3 O 3.2 N 0.22 hot pressed Mean square displacement ( D ) for Li motion 10 -11 Li 2 Si 0.7 P 0.3 O 3 N 0.18 sintered Ortho Li 3 PO 4 crystallizes with slow quench 10 -12 2.6 2.7 2.8 2.9 3.0 3.1 3.2 3.3 3.4 3.5 Pyro and meta phosphate share corners, LiSiPON 1000/T (K -1 ) form glasses MAGIC metastable and glassy ionic conductors IONICS review 2019 Nancy Dudney June 7, 2019 5 e

Challenges and Potential Technical Partnerships ‣ Need more control of gases through induction plasma torch. (tool design Tekna or other) ‣ How to consolidate glass powders so no boundaries? (glass processing Saint Gobain) ‣ Both sputtering and plasma torch are expensive, but will come down tuned Expense Sputter IPT for for Ar ($$ being 1-10 $/m 2 ) thin film powder Precursors / targets $$ $ $ Process – Watt : Watt $$ $$ Yield when optimized 10 90% 15 85% Direct film on cathode 0 0 Self-support sheet 0 ($ TBD) nucleate Watt for watt, both processes ≈ rate gas quench Material loss needs to be eliminated Then both viable price at scale - if Find MAGIC composition that is ductile. electrolyte is very thin.

T2M 9 th Q end 10 th Q 5 full cells of ‣ Final goals – by end of project 5 cm 2 , 0.3 mAh/cm 2 – Larger cells (with sputtered MAGIC) 1 mA/cm 2 , – Mechanical and thermal properties for full composition range 100 cycles ‣ Beyond – Nano-powders* promising, further pre-pilot work needed <30% degrade 2 MPa-m 1/2 , K 1c – Modified plasma torch complete range, LiPON to LiSiON 200 MPa, flex – Larger lot of powder Li + conductive $10/m 2 – Explore advanced manufacturing • *provisional patent Large scale sputtering is a viable option. Images from ORNL brochure Powders of oxynitride glass provide alternative processing. Will a dense, sintered glass membrane effectively resist Li filaments and dendrites? June 7, 2019 MAGIC metastable and glassy ionic conductors IONICS review 2019 Nancy Dudney 7

Recommend

More recommend