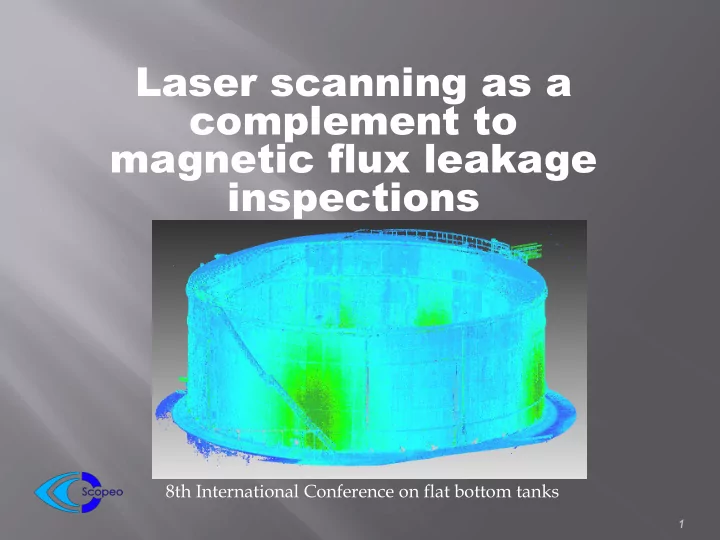

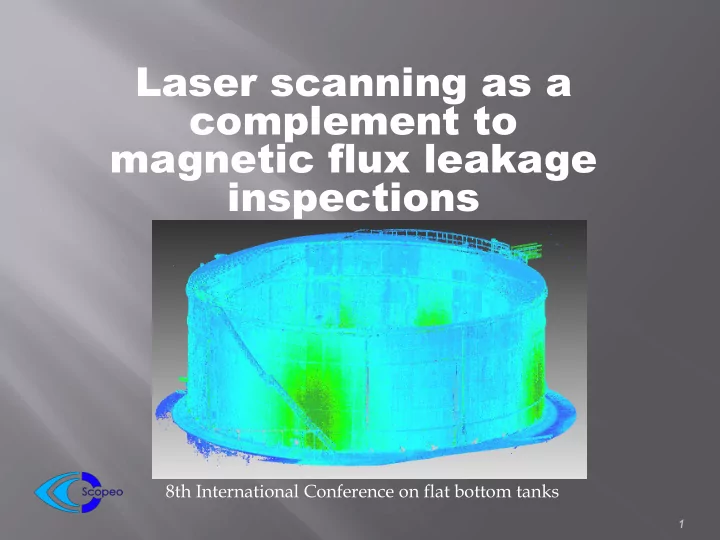

Laser scanning as a complement to magnetic flux leakage inspections 8th International Conference on flat bottom tanks 1

Introduction Since 1997 the storage tank operators and refineries have been inspecting tanks floors by Magnetic Flux Leakage method, and we have seen a lot of inspection companies use these system. This method has been a great innovation for the tank inspection. 2

Quick inspection for a large area. • Recognize by any code repair • Discriminate internal and external defects. • New maintenance practice • magnets sensor Plate 3

A important corrosion area top side plate. 4

Cylindrical pits less 15mm diameter 5

The volume loss of the metal for these both pits are similar 6

Plate curvature or bulges can prevent the sensor head from remaining in close proximity to the inspection surface. 7

False echo 8

These systems don't have to detect defects in welds 9

Following HSE Research Report 481, for the • inspection of storage tanks there needs to be a team of operators. This inspection team should consist of at least two individuals and possibly three. The roles required of the inspection team can be described as: • Team Leader (TL) • MFL Technician (MT) • Ultrasonic Technician (UT) 10

• Report all indications marked on the floor 11

Scanning by laser-scanner of tank floor : • 12

Defects measurements 13

We complete our inspection by a drawing: • 14

• The floor geometric deformations 15

• The annular geometric deformations 16

• The result of the planar tilt 17

• Out of verticality of the shell 18

• Out of roundness of the shell 19

• Dome roof inspection 20

• The beam Inspection 21

The scanner laser has to carry out: A complete inspection report of the bottom tank A complete geometrical analysis of tank A monitoring deformations in time 22

« Observe is our job » 23

Recommend

More recommend