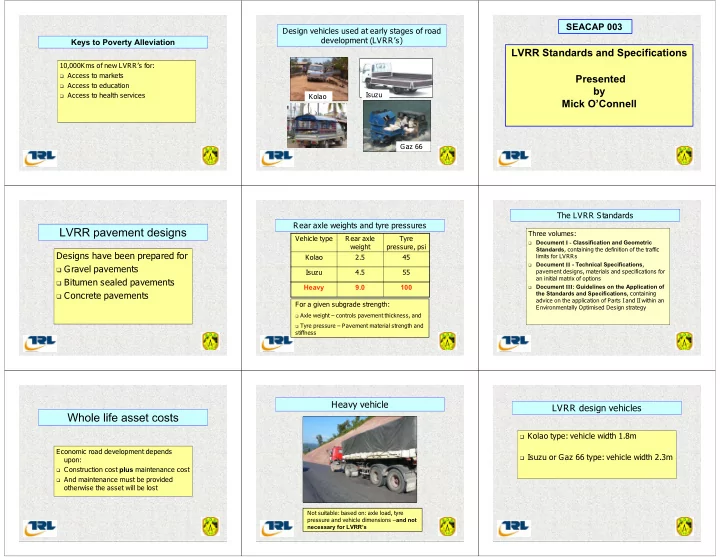

SEACAP 003 Design vehicles used at early stages of road development (LVRR’s) Keys to Poverty Alleviation LVRR Standards and Specifications 10,000Kms of new LVRR’s for: � Access to markets Presented � Access to education by � Access to health services Isuzu Kolao Mick O’Connell Gaz 66 7 4 1 The LVRR Standards Rear axle weights and tyre pressures Three volumes: Vehicle type Rear axle Tyre � Document I - Classification and Geometric weight pressure, psi Standards , containing the definition of the traffic Designs have been prepared for Kolao 2.5 45 limits for LVRRs � Document II - Technical Specifications , � Gravel pavements Isuzu 4.5 55 pavement designs, materials and specifications for an initial matrix of options � Bitumen sealed pavements � Document III : Guidelines on the Application of Heavy 9.0 100 � Concrete pavements the Standards and Specifications , containing advice on the application of Parts I and II within an For a given subgrade strength: Environmentally Optimised Design strategy � Axle weight – controls pavement thickness, and � Tyre pressure – Pavement material strength and stiffness 8 5 2 Heavy vehicle LVRR design vehicles � Kolao type: vehicle width 1.8m Economic road development depends � Isuzu or Gaz 66 type: vehicle width 2.3m upon: � Construction cost plus maintenance cost � And maintenance must be provided otherwise the asset will be lost Not suitable: based on: axle load, tyre pressure and vehicle dimensions – and not necessary for LVRR’s 9 6 3

Gravel road designs Road subgrades - Lao climate Gravel roads are suitable when: � Gravel loss is low and Pavement Construction Maintenance � Rainfall 1600mm to +3000mm � Maintenance regime and funding for � 7.5 months wet season routine and periodic (regravelling) is Gravel Low High � Evaporation less than rainfall for high, and assured � Health and safety targets are met most months Sealed Medium Medium (dust and visibility) � Subgrades are expected to be wet Concrete high Low Frequently these requirements cannot be assured: Pavement designs currently based on soaked Because of climate (rainfall), terrain (steep gradients> strength designs (soaked CBR strength) 6%, maintenance funding - also depletion of resources 16 13 10 Designs: Gravel Traffic groups A and B for pavement loading Traffic Group A Traffic Group B (esa’s) Subgrad Layer Subgrade Layer e Pavement Layer Thickness Soaked Pavement Layer Thickness D Soaked D (mm) CBR% (mm) � Group A < 10,000 esa’s � Therefore the designs include the CBR% Wearing Course 200 Wearing Course 200 options of sealed or concrete � Group B > 10,000 to 100,000 esa’s 2-3.9 2-3.9 Capping Layer 250 Capping Layer 300 pavements Wearing Course 200 Wearing Course 200 4-6.9 4-5.9 Capping Layer 100 Capping Layer 150 � A lowest asset cost decision can Wearing Course Wearing Course 200 be made on the most economic >7 200 6-7.9 Capping Layer Capping Layer 100 according to availability of esa’s are found by counting or estimating the Wearing Course 200 >8 construction materials and other Capping Layer 0 cumulative total of Kolao and Isuzu (Gaz) type of factors vehicles, factored as necessary. 17 14 11 Designs: Bitumen sealed Capping layers Subgrade Pavement Traffic Group A Traffic Group B Soaked Layer Layer Thickness Layer CBR% (mm) Thickness (mm) In the designs capping layers are used Surface Seal Seal instead of thicker sub-bases and road Base 100 100 bases to keep the upper pavement as 2-3.9 Sub-Base 100 150 economical as possible. They provide: Capping Layer 200 275 Surface Seal Seal Base 100 100 � Best use of local materials without 4-6.9 Sub-Base 100 150 demanding sub-base quality Capping Layer 100 175 � A good construction platform Surface Seal Seal Base 100 100 � A raised road and drier (stronger) 7-10.9 Sub-Base 100 150 conditions in the upper pavement Capping Layer 0 100 Surface Seal Seal Base 100 100 Requirement for a capping layer is CBR 10% >11 Sub-Base 100 150 Capping Layer 0 0 18 15 12

Framework: Phase 1 processes Design: concrete For Phase 1: Project road within LVRR envelope? � For LVRR’s Longitudinal pavement Subgrade Pavement Layer Traffic Group A Traffic Group B � Soaked Layer Thickness Layer Thickness and surfacing design for the target Outline suitable road dimensions � CBR% (mm) (mm) road is not necessarily constant, Overview of material resources � Surface (concrete) 150 150 � It is based on providing ALL Likely budget available, suitable for Spot 2-6.9 � Sub-Base 150 150 WEATHER ACCESS Improvement or EOD. Reassess - will road meet accessibility � Surface (concrete) 150 150 >7 Sub-Base 100 100 objective? If yes, proceed to Phase 2 Usually pavement design provides for different thicknesses of pavement as subgrades vary but the perception is of one pavement for the link; gravel, sealed or concrete; this is not necessary 25 22 19 Framework: Phase 2 processes Spot Improvement and Environmentally optimized design EOD Pavement material quality: sealed designs For Phase 2: � The most suitable (WLAC) design is Detailed assessment of traffic � Based on lower tyre pressures than heavy used for a given length of the target road, Road alignment technical survey for trucks, the road base material quality can � according to ACCESS rule hydrological design and subgrade strength be reduced: � Basic: Improve the road at the “trouble” leading to detailed road and pavement � Very light CBR 25% spot to provide all weather access for the � design, and Bill of Quantities lowest (WLAC) � Kolao type only CBR 50% � EOD provide the most suitable (WLAC) � Other CBR 80% for a series of target road sub-lengths, let it be: gravel, sealed or concrete. 26 23 20 SEACAP 003 Summary of pavement material quality Framework for Pavement Design Selection Traffic Group A Traffic Group B A two phased process: Pavement Unsealed Sealed Unsealed Sealed Phase 1: General Assessment of Pavement layer GWC Flexible GWC Flexible Options CBR% CBR% CBR% CBR% Phase 2: LVRR pavement and surfacing LVRR Standards and Specifications Base/GWC 25 50 25 80 option design Sub-Base NA 25 NA 25 Capping 10 10 10 10 Thank you For concrete roads the requirements for pavement layer materials in all subgrade categories are: Requirements for the elements of each Phase are Concrete, minimum 28-day cube strength: 20 MPa detailed in Document III and its appendices Sub-base CBR 25% 27 24 21

Recommend

More recommend