18 TH INTERNATIONAL CONFERENCE ON COMPOSITE MATERIALS Leave as it is. LENGTH-SCALE-DEPENDANT STRENGTHENING OF PARTICLE-REINFORCED METAL MATRIX COMPOSITES WITH STRAIN-GRADIENT PLASTICITY Y. S. Suh 1 *, M. S. Park 1 , S. Song 2 1 Department of Mechanical Engineering, Hannam University, Daejeon, Korea, 2 Department of Mechanical Engineering, Graduate School, Hannam University, Daejeon, Korea * Corresponding author (suhy@hannam.kr) Keywords : particle-reinforced metal matrix composites, strain-gradient plasticity, averaged-at- nodal plastic strain, finite-element modeling, length scale is also a similar concept as the punched zone 1 Introduction Particle-reinforced metal matrix composites modeling proposed by Suh et al. [5]. exhibits length scale in strength: smaller particle Punched zone modeling, however, has some leads to higher strength for the same particle volume. limitations: first, the accurate determination of This is usually distinct with the higher particle punched zone size around the complex particle volume fraction. Arsenault and Shi [1], Lloyd [2], geometry is not easy (only applicable for simple and Nan and Clarke [3] attributed such feature to the geometries such as a sphere) or, in most cases, additional dislocation density that is necessary to impossible. Second, it is only good for the regularly arranged particles. If the particles are clustered and accommodate large thermal misfit strains between the particles and the matrix. This additional the plastic deformation around a particle touches that geometrically necessary dislocation (GND) density of neighbor unit cell, the calculated punched zone over and above the preexisting statistically stored size will not be applicable. In this work, we have dislocation density is believed to cause the increased implemented strain gradient plasticity into Abaqus yield strength of the composite as presented UHARD and URDFIL to carry out a finite-element numerically by Qu et al. [4]. More recently, Suh et al. analysis on length-scale-dependent strengthening of [5] demonstrated the length scale of the strength of particle-reinforced metal matrix composite. We particle-reinforced composites with an augmented included cooling (quench hardening) as a first stage in order to take account of length scale effect due to unit-cell axisymmetric finite element model in such a way that the punched zone is represented as a fixed dislocation punching. This makes the modeling of fraction of the matrix endowed with higher strength enhanced strength zone unnecessary and therefore (due to the GNDs) than the rest of the matrix. provides the greater freedom of taking various shape Following Suh et al. [5], Shao et al. [6] showed and arrangement of particles in the strength analysis. similar strengthening effect using the Taylor-based Further strengthening due to elastic-plastic mismatch nonlocal theory of plasticity in addition to punched is predicted by the strain gradient plasticity. Qu et al. zone modeling. Taupin et al. [7] also proposed a new [4] also included quench hardening at the initial stage but they added the enhanced strength due to mean field approach including an internal length scale in order to capture the particle size effects on thermal mismatch uniformly throughout the matrix, the overall mechanical behavior of particle- which is not appropriate since the dislocation reinforced alloys. They employed a generalized self- punching due to thermal mismatch takes place along consistent scheme (with coated particles), with a or near the particle – matrix interface as shown by new “phase” representing the “layers” where orderly Suh et al. [5]. dislocations between the matrix and the particles are present. The thickness of these “ layers” is the 2 Theoretical Background and Modeling internal length scale introduced in the model, which Taylor dislocation model for normal yield stress is expressed as following [8]:

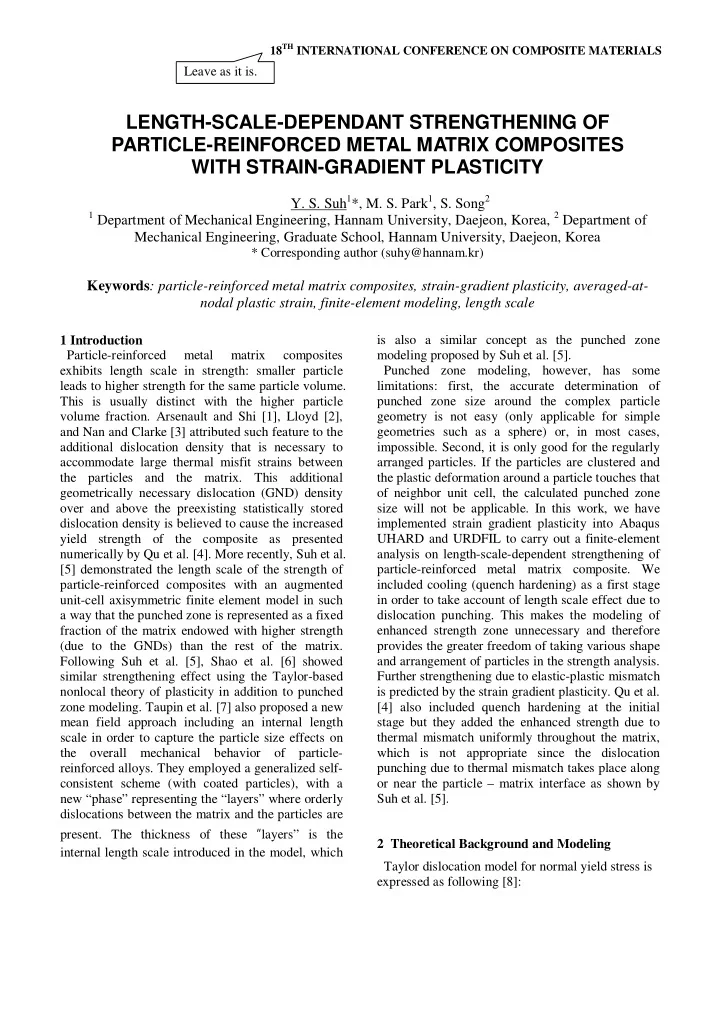

stress – true strain behavior of the unit-cell is σ = α ρ + ρ obtained from the extensional displacement and the (1) m G b ssd gnd tensile force generated on the top boundary. After the entire cell had been cooled down by 474 ℃ , ρ ρ Where, and are statistically stored ssd gnd upward displacement was applied. The mechanical dislocation (SSD) density and geometrically properties for the matrix A356-T6 and the particle necessary dislocation (GND) density, respectively. SiC were taken from Qu et al. [2] and Suh et al. [3]. m, G, b are Taylor factor, shear modulus of elasticity, magnitude of Burgers vector, respectively, and α is 3 Results and Discussions an empirical coefficient of order of magnitude of one. In case of uniaxial tensile test, GND becomes 3.1 Spherical particulate composites ρ = zero ( ) and the stress-strain relation can be 0 gnd The predicted composite true stress – true strain σ = σ u ε expressed as . Then SSD density ( ) curves with spherical particle are presented in Fig. 1. p ρ = σ α The predicted responses show distinct length scale 2 becomes . On the other hand, ( / mGb ) ssd u depending on the particle size. As observed in the ρ = η GND density can be expressed as r / b previous works [2, 3], SiC p /A356 composites may gnd where r is the Nye factor and η is the plastic strain have interfacial failure at larger strains. Since the gradient. So the equation (1) can be expressed as present model was assumed to have perfectly bonded interface, the discrepancy at larger strains are not of concern. Strain gradient distributions σ = σ + α η 2 2 (2) ( m G ) r b u immediately after the cooling and at the straining of 0.015 are shown in Fig. 2. It is noted that the strain Note that the hardening equation (2) is dependent on gradient after cooling (which can be related to the the plastic strain gradient as well as plastic strain. GND) is higher with larger strain and smaller The plastic strain gradient is expressed as following particle size, yielding more distinct size effect. [8]: Present results along with Suh et al.’s [3] clearly indicate that the strain gradient distribution after ′ ′ η = 2 η ijk η (3) 1 cooling is closely relevant with the dislocation ijk punching zone. η ′ is the deviatoric strain gradient tensor of where ijk η ′ = η − δ η + δ η 1 but incompressibility ( ) ijk ijk 4 ik jpp jk ipp 500 ε = η ′ = η p of plastic deformation ( ) gives and 0 kk ijk ijk 400 the plastic strain gradient tensor is the following Ture Stress (MPa) equation. 300 η = η ≡ = ε + ε − ε p p p (4) u Lloyd (7.5 µ m) ijk jik k , ij ki , j kj , i ij , k 200 Lloyd (16 µ m) Predicted (2 µ m) For computation, Abaqus v. 6.9 was used with the Predicted (7.5 µ m) 100 Predicted (16 µ m) user program UHARD for the equation (2) and Matrix only URDFIL for the equation (3) and (4). Plastic strain 0 gradient with the low order elements is evaluated by 0 0.01 0.02 0.03 0.04 0.05 using an isoparametric interpolation of averaged-at- Ture Strain nodal plastic strain. A quarter of an axisymmetric unit cell was modeled. A uniform upward Fig. 1. Comparison of numerical and experimental displacement is prescribed along the top boundary, [5] composite true stress–strain curves for 2, 7.5 and while the right boundary remains traction-free and 16 µ m diameter SiC particles at 15% volume straight during deformation. The composite true fraction.

Recommend

More recommend