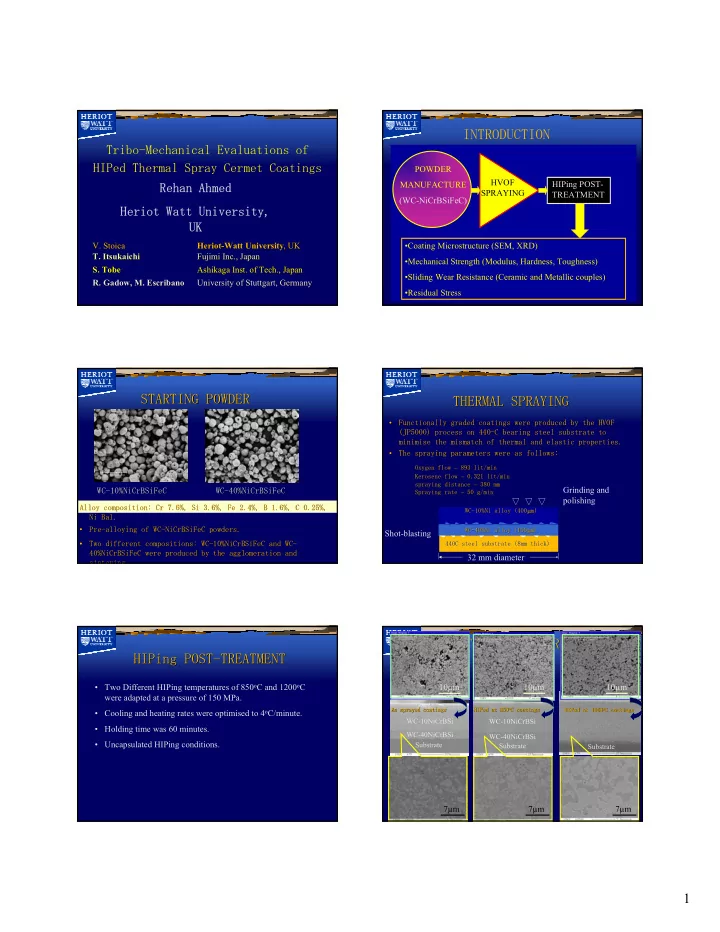

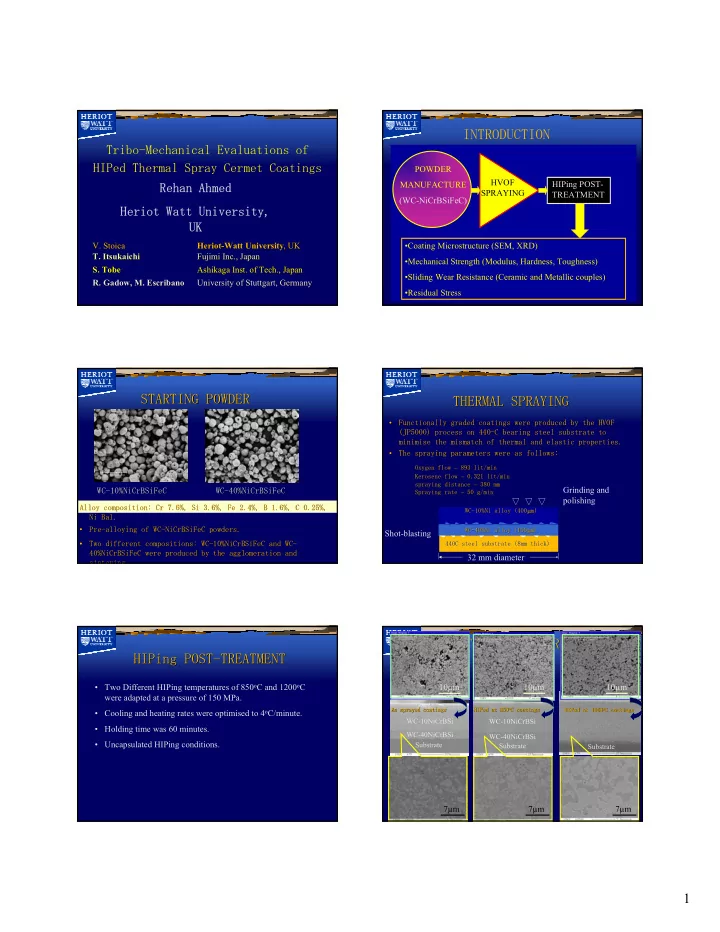

INTRODUCTION Tribo-Mechanical Evaluations of The aim of this investigation was to integrate the potential benefits •The aim of this investigation was to integrate the potential benefits of two process technologies of thermal spraying and HIPing to of two process technologies of thermal spraying and HIPing to HIPed Thermal Spray Cermet Coatings POWDER improve coatings tribo-mechanical performance. improve coatings tribo-mechanical performance. HVOF MANUFACTURE HIPing POST- Rehan Ahmed The specific objectives were to improve coating strength and SPRAYING The specific objectives were to improve coating strength and wear TREATMENT wear resistance by : (WC-NiCrBSiFeC) resistance by : Heriot Watt University, •Improve intersplat cohesion. •Improved intersplat cohesion by HIPing post-treatment. UK •Transform the mechanism of coating adhesion from mechanical •Transform the mechanism of coating adhesion from mechanical interlock to metallurgical bonding. V. Stoica V. Stoica Heriot Heriot- -Watt University Watt University , , UK UK •Coating Microstructure (SEM, XRD) interlock to metallurgical bonding. T. Itsukaichi Fujimi Inc., Japan T. Itsukaichi Fujimi Inc., Japan •Improve the homogeneity and crystallinity of coating •Mechanical Strength (Modulus, Hardness, Toughness) •Improve the homogeneity and crystallinity of coating microstructure. S. Tobe Ashikaga Inst. of Tech., Japan microstructure. S. Tobe Ashikaga Inst. of Tech., Japan •Sliding Wear Resistance (Ceramic and Metallic couples) R. Gadow, M. Escribano R. Gadow, M. Escribano University of Stuttgart, Germany University of Stuttgart, Germany •Residual Stress STARTING POWDER STARTING POWDER THERMAL SPRAYING THERMAL SPRAYING • • Functionally graded coatings were produced by the HVOF Functionally graded coatings were produced by the HVOF (JP5000) process on 440- -C bearing steel substrate to C bearing steel substrate to (JP5000) process on 440 minimise the mismatch of thermal and elastic properties. minimise the mismatch of thermal and elastic properties. • • The spraying parameters were as follows: The spraying parameters were as follows: Oxygen flow Oxygen flow – – 893 lit/min 893 lit/min Kerosene flow – – 0.321 lit/min 0.321 lit/min Kerosene flow spraying distance spraying distance – – 380 mm 380 mm Grinding and WC WC- -10%NiCrBSiFeC 10%NiCrBSiFeC WC- WC -40%NiCrBSiFeC 40%NiCrBSiFeC Spraying rate Spraying rate – – 50 g/min 50 g/min polishing Alloy composition: Cr 7.6%, Si 3.6%, Fe 2.4%, B 1.6%, C 0.25%, Alloy composition: Cr 7.6%, Si 3.6%, Fe 2.4%, B 1.6%, C 0.25%, 10%Ni alloy (400 µ µ m) WC- WC -10%Ni alloy (400 m) Ni Bal. Ni Bal. • • Pre- Pre -alloying of alloying of WC WC- -NiCrBSi NiCrBSiFeC FeC powders. powders. µ m) WC- WC -40%Ni alloy (100 40%Ni alloy (100 µ m) Shot-blasting • • Two different compositions: WC- Two different compositions: WC -10% 10%NiCrBSi NiCrBSiFeC FeC and WC and WC- - 440C steel substrate (8mm thick) 440C steel substrate (8mm thick) 40%NiCrBSi 40% NiCrBSiFeC FeC were produced by the were produced by the agglomeration and agglomeration and 32 mm diameter sintering sintering COATING MICROSTRUCTURE COATING MICROSTRUCTURE HIPing POST HIPing POST- -TREATMENT TREATMENT • Two Different HIPing temperatures of 850 o C and 1200 o C 10µm 10µm 10µm were adapted at a pressure of 150 MPa. As sprayed coatings As sprayed coatings HIPed at 850 o HIPed at 850 o C coatings C coatings HIPed at 1200 o o C coatings C coatings HIPed at 1200 • Cooling and heating rates were optimised to 4 o C/minute. WC-10NiCrBSi WC-10NiCrBSi • Holding time was 60 minutes. WC-40NiCrBSi WC-40NiCrBSi • Uncapsulated HIPing conditions. Substrate Substrate Substrate 7µm 7µm 7µm 1

XRD EVALUATIONS XRD EVALUATIONS XRD EVALUATIONS XRD EVALUATIONS -WC Sprayed and HIPed coatings Sprayed and HIPed coatings WC Powder vs. Sprayed Coating Powder vs. Sprayed Coating -WC WC -FeW 3 C WC -WC -WC -Ni 2 W 4 C -FeW 3 C -WC -WC -WC -Ni 2 W 4 C -WC -WC -Ni 4 B 3 -Ni 4 B 3 -Ni 5 Si 2 -Ni 2 Si -Ni 3 B HIPed at 1200 o C -Ni -WC -FeW 3 C -WC -WC -WC -WC -WC -WC -WC -Ni 2 W 4 C -W 2 C -WC HIPed at 850 o C -WC -W 2 C -WC -FeW 3 C -Ni -WC -Ni 3 B -W -W 2 C -W 2 C As-sprayed coating -Ni -WC W -WC -WC -W 2 C -WC -WC -WC -FeW 3 C -WC -WC -Ni -WC -WC -Ni 3 B -W 2 C -W 2 C -WC As-sprayed coating -Ni -NiB -WC -Ni Starting powder 10 20 30 40 50 60 70 80 90 10 20 30 40 50 60 70 80 90 INDENTATION MODULUS =E(1- INDENTATION MODULUS =E(1 - MIROHARDNESS EVALUATIONS MIROHARDNESS EVALUATIONS ν 2 Surface ν 2 ) ) WC-40%NiCrBSi WC-10%NiCrBSi WC-40%NiCrBSi 450 WC-10%NiCrBSi Indentation Modulus (GPa) Substrate 400 1400 350 As-Sprayed 1200 300 HIPed at 850 o C 250 Vickers Hardness 1000 200 HIPed at 1200 o C 800 150 600 As-sprayed 100 50 400 HIPed at 850 0 HIPed at 1200 200 0 50 100 150 200 250 300 350 400 0 Distance from Surface (µm) 0 50 150 250 350 450 Distance from Surface (µm) SEM observations: HVOF coatings SEM observations: HVOF coatings INDENTATION TOUGHNESS INDENTATION TOUGHNESS Cryogenic fractured coatings Cryogenic fractured coatings pores micro-cracks pores Cracks 200 µ m 200 µ m 200 µ m As As- -sprayed coating sprayed coating HIPed at 850 o C coating HIPed at 1200 o HIPed at 1200 o C coating C coating As sprayed coatings As sprayed coatings HIPed at 850C coatings HIPed at 850C coatings HIPed at 1200C coatings HIPed at 1200C coatings HIPed at 850 o C coating 2

SLIDING WEAR: SLIDING WEAR: SLIDING WEAR TESTS SLIDING WEAR TESTS COATING VOLUME LOSS COATING VOLUME LOSS Test conditions Test conditions 0.014 Coatings Vs steel, 12N load Normal load Normal load Counter Body 440C Steel Coatings Vs steel, 22N load 0.012 Volume loss (mm 3 ) (balls) Si Si 3 3 N N 4 4 ceramic ceramic 0.01 Coatings Vs ceramic, 12N load Coatings Vs ceramic, 22N load Load 12 and 22 N 0.008 Ball 0.006 Sliding Speed 0.012m/s 0.004 Coating Dry/Lubricate Dry 0.002 d Sliding direction Sliding direction 0 As-sprayed HIPed at 1200 o C HIPed at 850 o C Reciprocating ball on plate apparatus Reciprocating ball on plate apparatus SLIDING WEAR: WEAR SCARS SLIDING WEAR: WEAR SCARS SLIDING WEAR: TOTAL VOLUME LOSS SLIDING WEAR: TOTAL VOLUME LOSS Three dimensional interferometric plots of the coatings Three dimensional interferometric plots of the coatings tested against ceramic balls (load – – 22N) 22N) tested against ceramic balls (load Total volume loss – Total volume loss – Coatings Vs steel balls Coatings Vs steel balls 1 Total volume loss (mm 3 ) 0.8 Total volume loss, 12N load As- As -sprayed coating sprayed coating 0.6 Total volume loss, 22N load 0.4 0.2 0 As-sprayed HIPed at 850 o C HIPed at 1200 o C HIPed at 850 HIPed at 850 o C coating C coating HIPed at 1200 o C coating HIPed at 1200 C coating 1.4 Friction coefficient SLIDING WEAR: TOTAL VOLUME LOSS SLIDING WEAR: TOTAL VOLUME LOSS FRICTION FRICTION 1.2 1 Total volume loss Total volume loss – – Coatings Vs ceramic balls Coatings Vs ceramic balls 0.8 0.1 0.6 As-sprayed Ball volume loss, 12N load HIPed at 850 o C 0.4 Coating volume loss, 12N load 0.08 HIPed at 1200 o C 0.2 Total volume loss (mm 3 ) Time (mins) 0 100 200 300 400 500 600 0.06 Coatings Vs steel balls (load - - 22N) 22N) Coatings Vs steel balls (load Ball volume loss, 22N load Coating volume loss, 22N load 1.4 Friction coefficient 0.04 1.2 1 0.02 0.8 0.6 As-sprayed 0 0.4 HIPed at 850 o C As-sprayed HIPed at 850 o C HIPed at 1200 o C 0.2 HIPed at 1200 o C Time (mins) 0 100 200 300 400 500 600 Why improvement in wear resistance? Coatings Vs ceramic balls (load - Coatings Vs ceramic balls (load - 22N) 22N) 3

Recommend

More recommend