Improved Superabsorbers Based on Sulfonated Pulps Art J. Ragauskas

PROJECT OBJECTIVE The objective of the proposed work is to provide a new technology to enhance the water absorption properties of fully bleached softwood and hardwood Kraft pulps by 20 – 50% This goal will be accomplished by sulfonating the carbonyl groups that are present in bleached Kraft pulps The results of this study will be a novel treatment for improving the water absorbency properties of tissue, towel and fluff pulp This project will provide a viable alternative to petroleum derived superabsorbers may used in modern products

Superabsorbers Superabsorbers are polymers, effectively absorb water, hydrophilic cross-linked, cannot dissolve because of their three-dimensional polymeric network structure In the past 50 years, research in the field of superabsorbents developed rapidly because of increasing demand Most superabsorbents are non-biodegradable polymer-based products, the renewed public attention favoring environmentally benign products has encouraged the development of biodegradable superabsorbers based on cellulosic material

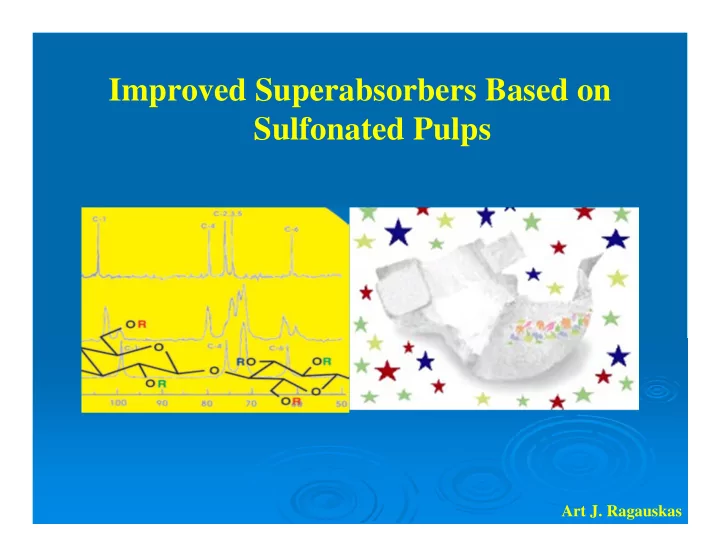

Functionalized Cellulose Oxidized cellulose, without chain cleaved, characterization and derivatization Sulfonate oxidized cellulose, as disposable absorbent products

OH OH O O Oxidation - O IO 4 O HO O O OH OH O Sulfonation O HO OH - SO 3 - O 3 S Current Cellulose Modifications

FQA measurement of cellulosic samples ENTRY Arithmetic FQA Length (mm) 0.809 HW Original 0.794 Oxidation Low 0.741 Oxidation High 0.771 Sulfonation Low 0.683 Sulfonation High 0.705 Birch Original 0.675 Oxidation Low 0.649 Oxidation High 0.658 Sulfonation Low 0.632 Sulfonation High

Copper Number & Total Sufonation Group of Various Samples Entry Total acid group (mmol/100 g o.d. fibers) Cellulose Cu # = 0.68 2.00 Oxidation 1: Cu # = 5.11 1.87 Sulfonation of Oxidation 1 3.55 Oxidation 2: Cu # = 7.13 1.79 Sulfonation of Oxidation 2 5.90 ECF Bleached Birch Cu # = 0.46 6.56 Oxidation 1: Cu # = 4.29 5.08 Sulfonation of Oxidation 1 6.94 Oxidation 2: Cu # = 5.98 3.50 Sulfonation of Oxidation 2 7.21

AFM of Native and Modified Cellulosics Original Oxidized Sulfonated Bleached HW Pulp Bleached Birch Kraft

SEM Images of Native and Modified Cellulosics Oxidized Sulfonated Low High Bleached HW Pulp

WRVs` ECF Bleached Birch Kraft Pulp 1.8 1.6 1.4 1.2 WRV (g/g) 1 0.8 0.6 0.4 0.2 0 Birch Original Birch Oxidized 1 Birch Sulfonated 1 Birch Oxidized 2 Birch Sulfonated 2 ECF Bleached HW Pulp 0.7 Sulfonation of Cu # 0.6 Provides higher WRV 0.5 0.4 WRV (g/g) 0.3 0.2 0.1 0 Buckeye Original Buckeye Oxidized 2 Buckeye Sulfonated 2

Preliminary Research Results Sulfonation of bleached pulps with elevated Cu # increases WRV up to 50% The impacts of these modifications were studies including fiber dimensions, carbonyl, acid groups and their corresponding water absorbency properties as well as morphological changes

Oxycellulose Content of Kraft ECF Pulps 0.7 All Bleached Kraft Pulps have a Cu # 0.6 0.5 0.4 Cu # 0.3 0.2 0.1 0 Kraft-A Kraft-A Kraft-A Kraft-A Kraft-A Kraft-A Kraft-B Kraft-B

Oxycellulose Content of Kraft ECF Pulps 1.4 1.2 1 0.8 Cu # 0.6 0.4 0.2 0 ) D D ) ) ) ) ) ) ) ) W W ) W W W W 2 s Q u D t t S S S S S S f f A t a a - p ( ( ( ( ( ( t / r r s y S K K C C C C C C o l P a - - - - - - p t t t t t c t ( f f f f f f u W a a a a a a W E r r r r r r K K K K K K S S ( ( ( C C C - t - - f t a t f f a a r K r r K K

Proposed IPST@GT Research Determine Cu # of a series of ECF bleached kraft pulps and sulfonate Cu # to 0 to increase the WRVs Identify best pulps for enhanced cellulosic based superabsorber properties Investigate potential to enhance Cu # of ECF bleached kraft pulp via modified peroxide (H 2 O 2 /metal) or alternative oxidant followed by sulfonation and the relationship between the absorbent properties and their chemi-physical properties.

Thank You

Recommend

More recommend