Impact of Geothermic Well Temperatures and Residence Time on the - PowerPoint PPT Presentation

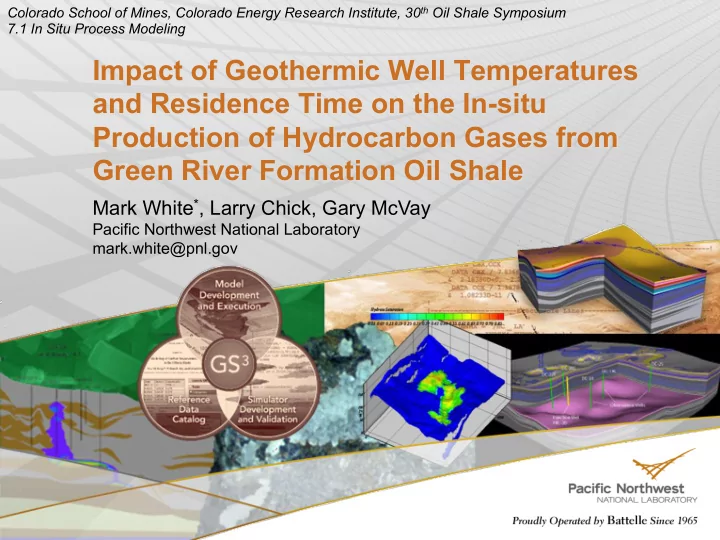

Colorado School of Mines, Colorado Energy Research Institute, 30 th Oil Shale Symposium 7.1 In Situ Process Modeling Impact of Geothermic Well Temperatures and Residence Time on the In-situ Production of Hydrocarbon Gases from Green River

Colorado School of Mines, Colorado Energy Research Institute, 30 th Oil Shale Symposium 7.1 In Situ Process Modeling Impact of Geothermic Well Temperatures and Residence Time on the In-situ Production of Hydrocarbon Gases from Green River Formation Oil Shale Mark White * , Larry Chick, Gary McVay Pacific Northwest National Laboratory mark.white@pnl.gov 1

Subsurface Simulation PNNL Environmental Stewardship • Radionuclide migration and remediation • Nuclear waste tank leakage • Vegetated surface barrier design • Freeze-wall technology Environmental Remediation • Carbon tetrachloride in deep vadose zone environment • Trichloroethylene in arid climate • Petrol-processing waste in shallow water table environment Geologic CO 2 Sequestration • Deep sedimentary saline formations • Deep basaltic saline formations • Methane hydrate formations with co-production Hydrocarbon Production • Alaska Northslope gas hydrate accumulations • Suboceanic gas hydrate accumulations • Piceance Basin oil shale • Enhanced oil recovery technologies

STOMP Overview Subsurface Transport Over Multiple Phases Operational Modes • STOMP-W, -WA, WAE -- Water-Air-Energy Operational Modes • STOMP-WO, -WOA, WOAE -- Water-Oil-Air-Energy Operational Modes • STOMP-WS, -WSA, WSAE -- Water-Salt-Air-Energy Operational Modes • STOMP-WCS, -WCSE -- Water-CO 2 -Salt-Energy Operational Modes • STOMP-WCMSE -- Water-CO 2 -CH 4 -Salt-Energy Operational Modes Implementations • Sequential (Fortran 90) • Scalable (Fortran 90/Global Arrays/PETSc) Licensing and Quality Assurance • Academic, U.S. Gov., Foreign Gov., Industrial • Documentation (Guides, Website, Publications) • Short Courses (University Sponsored) • DOE Order 414.1C (System Safety Software) Future • Geologic CO 2 sequestration • Hydrocarbon production • Petascale computing and beyond

Problem Description • 500-ft kerogen-rich interval above the water table • Fischer-Assay of 19 gal/ton • Geothermic well temperatures of 450˚, 550˚, and 650˚ C • Geothermic well power density of 2 kW/m • Hexagonal pattern spacings of 45 ft, 10 m, and 5 m. • Intrinsic porosity 0.22 • Intrinsic permeability 1 darcy • Induced fracture density 0.05 • Matrix compressibility 1.e-9 Pa -1 • Maximum induced fracture porosity 0.10

Mathematical Model • Conservation equations • Thermal energy (temperature) Molar Density • Heavy oil (HO volu. molar density) Equilibrium to • Light oil (LO volu. molar density) Eliminate Primary • Hydrocarbon gas (CH x volu. molar density) Variable Switching • Methane (CH 4 volu. molar density) (system pressure) • Phases • Nonaqueous phase liquid (mobile-compositional) • Gas (mobile-compositional) • Kerogen (immobile-single component) • Coke (immobile-single component) • Char (immobile-single component) Newton-Raphson • Constitutive equations Iteration • Physical properties • Chemical reactions • Phase equilibrium • Transport properties • Fracture model

Conservation of Energy • Heat transport by advection, gaseous diffusion/dispersion, phase transformations, component appearance and disappearance, heat of kerogen dissociation, but ignoring oil cracking heat of reaction. Algebraic form • Darcian advection • Fickian advection

Model Development • Model #1 • Thermal energy, Oil, H 2 , CO, CO 2 , CH 4 , C 2 H x , C 3 H x • Campbell et al. (1980a, 1980b) reaction network • Kerogen pyrolysis only, no oil cracking reactions • Simulations yielded high residual NAPL saturations • Model #2 • Thermal energy, C 50 H x , C 30 H x , C 18 H x , C 12 H x , C 8 H x , C 3 H x , CH 4 , H 2 , CO 2 • Fan et al. (2009) reaction network • Simulations yielded oil production lower than consistent for Green River Formation oil shales with Type 1 kerogens • Model #3 • Thermal energy, Heavy Oil, Light Oil, Hydrocarbon Gas, Methane • Modified Braun and Burnham (1993) reaction network • Kerogen pyrolysis and oil cracking reactions • Producing coke and char • Oil production consistent with Type 1 kerogens

Phase Equilibria • Peng-Robinson cubic equation of state • Modified version of Michelsen’s (1985) flash procedure • No binary interaction terms • Temperature dependent pure component parameters • Fugacity coefficients functions of phase composition, pressure and temperature • Michelsen’s scheme requires solution of three independent variables: • Modified scheme yielded increased stability and more rapid convergence by adding two equations:

Rock Permeability • Matrix Permeability • Induced Fracture Permeability • Dual-Continuum Permeability

Phase Relative Permeability • Gas Relative Permeability • Nonaqueous Phase Liquid Relative Permeability

Chemical Reaction Model • Linear combination of Arrhenius reaction rate equations

Approximations and Assumptions • Chemical Reactions and Component Species • 7 chemical species, 4 reactions (13 species, 10 reactions) • No H 2 O, H 2 , CO 2 , CO • Water vaporization ignored • Geomechanics • Empirical model that allowed fracture aperture to increase with pore pressure • Fracture permeability dependent on fracture aperture, absolute fracture roughness, and fracture density • Hydrologic Properties • Empirical model of matrix permeability as a function of kerogen, char, and coke saturations • Matrix and fracture moisture retention characteristics • Symmetry and Boundary Effects • Two-dimensional horizontal domain ignores end effects • Symmetry assumption requires active adjacent hexaagons

45-ft Hex 650˚C Geothermic Well

45-ft Hex 650˚C Geothermic Well

45-ft Hex 550˚C Geothermic Well

45-ft Hex 450˚C Geothermic Well

10-m Hex 650˚C Geothermic Well

10-m Hex 650˚C Geothermic Well

10-m Hex 550˚C Geothermic Well

10-m Hex 450˚C Geothermic Well

10-m Hex 450˚C Geothermic Well Temperature, color scaled from 40˚ to 440˚C 1 year 2 years 3 years 4 years 5 years 6 years

10-m Hex 450˚C Geothermic Well Kerogen saturation, colored scaled from 0.0 to 1.0 1 year 2 years 3 years 4 years 5 years 6 years

10-m Hex 450˚C Geothermic Well Liquid oil saturation, color scaled from 0.0 to 1.0 1 year 2 years 3 years 4 years 5 years 6 years

10-m Hex 450˚C Geothermic Well Coke saturation, color scaled from 0.0 to 1.0 1 year 2 years 3 years 4 years 5 years 6 years

5-m Hex 450˚C Geothermic Well

5-m Hex 450˚C Geothermic Well

Geothermic Well Power

Conclusions Reaction Networks • Reaction networks that only consider the primary kerogen decomposition process will yield residual liquid oil in the formation, which is not consistent with laboratory or field observations. • Char and coke formation are important pore filling processes that are required for accurate calculation of pore pressure and fluid expulsion. • Oil and gas recovery predictions are strongly dependent on the accuracy and appropriateness of the chemical reaction network, stoichiometry, and kinetics.

Conclusions Numerical Simulations • Oil production in terms of percent of Fischer Assay is strongly related to formation temperatures and residence time; where higher temperatures and longer residence times lower oil production, but favor gas production. • The production period is strongly related to geothermic well spacing, where larger spacings yield longer production periods. • Temperature limits on the geothermic wells cause the power required for these wells to decline during production.

Shell Oil Field Experiment MDP[s] • Maximum heater well temperature of 450˚C • 16 electric heaters in concentric patterns • Outer hexagon spacing of 19.5 ft • Intermediate hexagon spacing of 14.0 ft (rotated 90˚) • Inner diamond spacing of 8.5 ft • 113-ft heated interval between 280 to 393 ft bgs • 540-day experimental period • 1806 barrels of liquid oil recovered • 861 additional BOE of gas recovered • 2 simulations with STOMP-OS • 20 gal/ton Fischer Assay oil shale • 12 gal/ton Fischer Assay oil shale • Modified Braun and Burnham (1993) reaction network

MDP[s] Calibration Study (12 gal/ton FA) Temperature, color scaled from 40˚ to 440˚C

MDP[s] Calibration Study (12 gal/ton FA) Kerogen saturation, color scaled from 0.0 to 1.0

MDP[s] Calibration Study (12 gal/ton FA) Liquid-oil saturation, color scaled from 0.0 to 1.0

MDP[s] Calibration Study (12 gal/ton FA) Coke saturation, color scaled from 0.0 to 1.0

Shell Oil MDP[s] Calibration Study

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.