IMAGINE Imaging Station with cold neutrons S. Désert, A. Hélary, C. Loupiac, F. Ott Frederic.ott@cea.fr

IMAGING AT THE LLB An imaging station has been running for 30 years at the LLB : G45 Installed at the end of a cold neutron guide Uses films and image plates: spatial resolution ~50µm Very wide field of view (500x250mm²) (defined by the image plate size) The station is operated by the company A+ RTD (~3 operators) Used mostly for explosive materials (~5000 pieces / year) Limitation Access difficult for LLB physicists Access not allowed for external users The configuration is fixed to make sure the « industrial » configuration is not modified Key requirement for qualification issues with industrialists Very difficult to setup dedicated sample environments A facility dedicated to experimentalists is required 17 MARS 2014

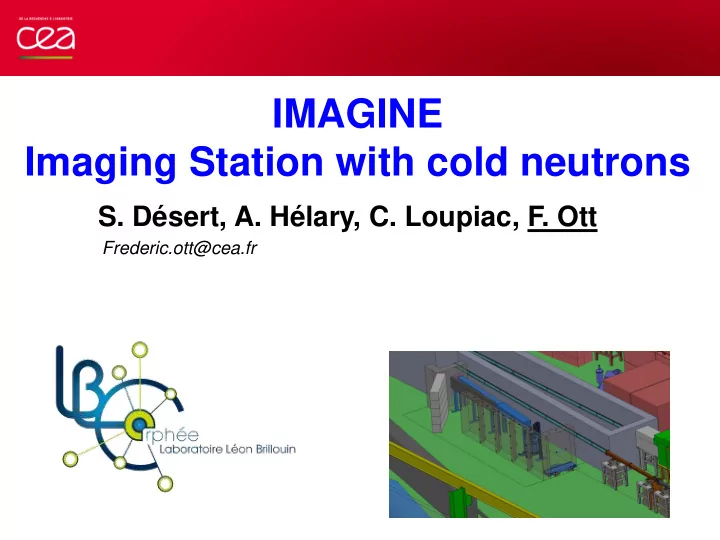

IMAGINE : IMAGING STATION WITH COLD NEUTRONS Main scientific case : agro-food applications + possibility to perform Bragg edge imaging + possibility to perform magnetic imaging + possibility to perform Time-Of-Flight imaging (preparatory to ESS) Main interest : high resolution imaging Installed at the position of the reflectometer EROS on the cold neutron guide 17 MARS 2014 G3bis

TECHNICAL CHARACTERISTICS Cold neutron guide G3bis: neutron spectrum ranging from 3A° to 20A° Whole experimental area on tanzboden All elements of the spectrometer can be moved around on air-cushion and can be easily swapped (collimator, sample table, detector) Source size from 6 to 25mm in diameter Flight path from 3-8m L/D ratio from 100 to 1000 Flux in a typical configuration (FOV = 80mm, source 20mm diameter, L = 4m): 2x10 7 neutrons/s/cm². Very low background noise The spatial resolution is presently limited to 200µm. Limitation due to the very wide aperture optical lens (f/0.95) Optics is being changed to go down to 50µm 17 MARS 2014 | PAGE 4

Acquisition sCMOS camera from Photonic Science 2048x2048 pixels Fast acquisition rate (10fps) Field of view 80x80 mm² Workstation for data acquisition processing Dell Precision T5600 64Go ram Interface with PINGOUIN (LLB acquisition system) RAID system for data storage (20To) Data processing For 2D pictures: ImageJ For tomography: no decision yet. 17 MARS 2014

17 MARS 2014

PHOTOS 17 MARS 2014 CEA | 10 AVRIL 2012 | PAGE 7

STATUS (March 2014) The station is operating Open for friendly users Call for proposals April 1 st Target to evaluate the resolution 100 µm scintillator, Outer ring : 500 µm Available sample environments Inner Ring: 100 µm Humidity chamber Liquid cells Furnace Heavy load sample table (~100kg)

UPGRADES Upgrades under way New camera box with new optics (Spring 2014) High spatial resolution ~50µm (smaller field of view) Velocity selector in the casemate (Summer 2014) Evaluation of Bragg edge imaging Polarized neutrons (Automn 2014) Foreseen upgrades Microchannel plate detector Further increase in spatial resolution and detection efficiency Time-of-flight measurements Chopper is readily available Requires a high resolution time resolved detector (microchannel plate?) 17 MARS 2014

TESTS EXPERIMENTS ALREADY PERFORMED Water diffusion in milk powders Porosity of corks for wine bottles Humidity Probing stir-welded joints Quantification of vineyard ‘s Quantification of defects and water root growth after Sorption on natural cork stoppers mycorhyzation

WATER DIFFUSION IN MILK POWDERS Observation of water diffusion in milk powders tablets Role of ingredients ( cellulose, lactose, maltodextrin ….) on dispersion Fields of Application: Instant powders, percolation, pharmaceutics … Milk powders tablet 0.64 1min 0.62 3h 6h Tablet 0.60 0.58 tablet Grey Level 0.56 Swelling 0.54 swelling 0.52 Water 0.50 water Tablet of milk powder 0.48 formulated with cellulose 0.46 0 2 4 6 8 10 12 14 16 18 20 22 24 26 28 Water diffusion mm Kinetics of water diffusion 17 MARS 2014 in tablet

POROSITY OF CORKS FOR WINE BOTTLES Evaluation of the different qualities: defects Impact of the compression Impact of water sorption on cork macroporosity Grade 0 after compression grade 0 (+) In the bottle grade 2 (-) 17 MARS 2014

OTHER TESTS PE screw with internal defect Bumblebee 17 MARS 2014

ACKNOWLEDGMENT E. Lehman (PSI) A. Kaestner (PSI) D. Mannes (PSI) G. Bayon (CEA-DEN) H. Bilheux (SNS) N. Kardjilov (HZB) B. Schillinger (FRM2) 17 MARS 2014

Workshop on Imaging at LLB prior to Neutrons and Food 3 7-9 july 2014 Including practical and possibility of testing your samples !!!!

Recommend

More recommend