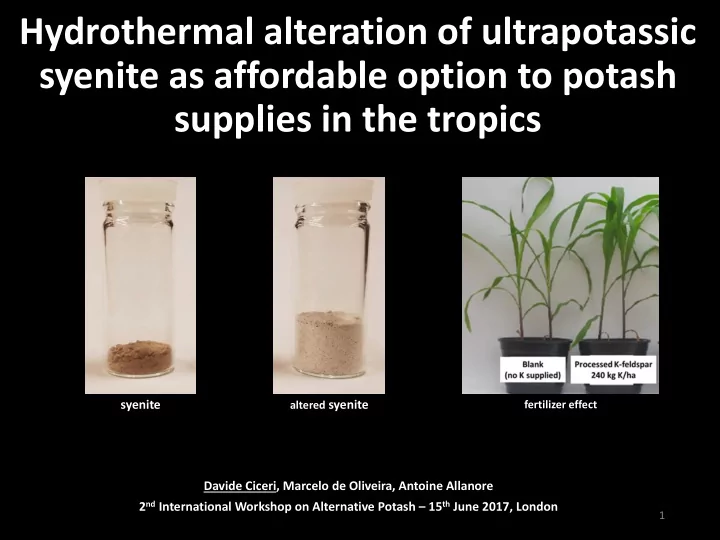

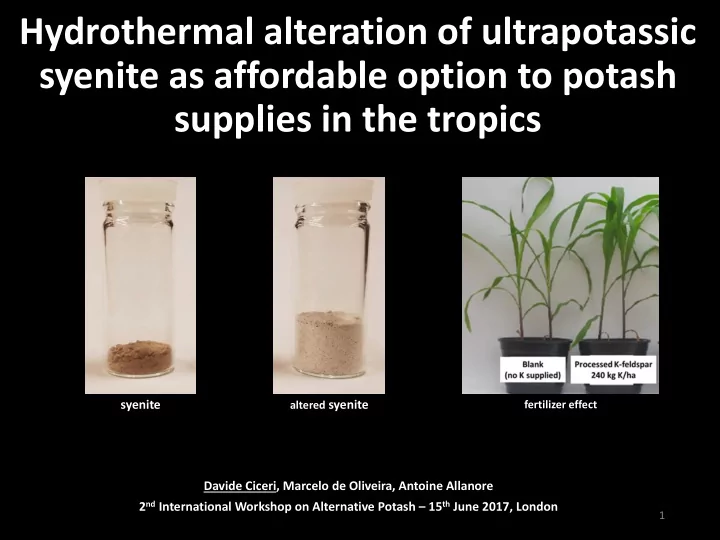

Hydrothermal alteration of ultrapotassic syenite as affordable option to potash supplies in the tropics syenite altered syenite fertilizer effect Davide Ciceri, Marcelo de Oliveira, Antoine Allanore 2 nd International Workshop on Alternative Potash – 15 th June 2017, London 1

FOOD SECURITY 795 million people are undernourished 2

FOOD SECURITY population growth availability arable accessibility lands quality FOOD SECURITY climate food loss change water resources 3 Premanandh 2011

FOOD SECURITY AVAILABILITY YIELDS ACCESSIBILITY COST QUALITY NUTRITION FERTILIZERS N-FERTILIZERS P-FERTILIZERS K-FERTILIZERS 30-40 GJ t -1 1-4 GJ t -1 1-4 GJ t -1 NH3 P2O5 K2O Steel: 15 GJ Glass: 35 GJ Wood: 7 GJ

POTASH PRODUCTION CONSUMPTION Skorina and Allanore ( 2015 ) SOIL FAO ( 2016 ) ALTERNATIVE FORMS OF POTASH? Brazilian oxysoil 5

ALTERNATIVE POTASH SOURCES Mason & Moore, Yaroslavsky, Poddervaart • Abundant In low-temperature, non-aggressive • Available (world-wide distribution; quarry) aqueous solutions, 1 mm crystal of K-feldspar dissolves in 520,000 • Relatively high grade ( ~ 15 wt % K 2 O) years. 6

GEOLOGY MATERIALS AGRONOMY SCIENCE 7

FELDSPAR CHARACTERIZATION • XRD (mineralogy) • XRF (elemental content) • Surface Area • Particle Size Distribution • Leaching 8 Ciceri et al. ( 2017 )

FELDSPAR CHARACTERIZATION Ciceri et al. ( 2015 ) Rate of K-feldspar dissolution is up to 1000 times faster than in a standard flow through system 9

MATERIALS SCIENCE Processing technology Pros/Cons • No K 2 O dilution; cheap; no waste comminution and/or mechano-activation of K- feldspar and microorganism-mediated • Limited experimental evidence; need of strict dissolution (bioweathering) experimental protocols. • K 2 O concentration calcination in presence of fluxes/additives • T ; waste; type of flux?; limited experimental data • Mild processing conditions; no waste alkaline hydrothermal alteration • K 2 O dilution; water • other resources (manure, seawater, algae, ashes, sugar beets liquors, etc.) • K 2 O content; abundance; limited know-how; scale up 10

HYDROTHERMAL PROCESSING 11

12

HYDROTHERMAL PROCESSING 13

MINERALOGICAL COMPOSITION 14

ELEMENTAL RELEASE K-feldspar hydrothermal material 15

CONCLUSION • Importance of fertilizers for global food security (potash) • Long-term research effort, from mine to processed product characterization of K-feldspar sources (Ciceri et al. 2017) processing technologies (Ciceri et al. 2015) characterization of processed material (Ciceri et al. in prep. ) • Hydrothermally altered K-feldspar as a promising alternative source of potash: mineralogy and potassium release ≈ 20 g K /kg HS at pH=5 (24h) • Preliminary economic considerations • Example of succesful partnership between industry and academia 16

ACKNOWLEDGEMENTS MIT team: Prof. Allanore, Dr. de Oliveira, Dr. Gadois, Dr. Skorina, Dr. Stokes, Dr. Sabatini, Ms. Berger, Mr. Grimonprez, Ms. Dolittle, Ms. McDunn, Mr. Sumitro, Mr. Blanchard, Mr. Martin, Ms. Kestin, Ms. Gutierrez, Mr. Sankararaman, Mr. Williams, Ms. Postak, Ms. Sypnievski, Mr. Kitcher., Mr. Martins, Mr. Buscemi, Mr. Zaharil H&M Analytical Services, Inc.: Dr. Steve Miller 17

EXTRA SLIDES 18

MINERALOGICAL COMPOSITION Conversion of K-feldspar K-feldspar: KAlSi 3 O 8 17.4 wt % Albite: NaAlSi 3 O 8 Hydrogrossular: Ca 3 Al 2 (SiO 4 ) 3− x (OH) 4 x Dicalcium silicate hydrate: Ca 2 (SiO 3 OH)(OH) Tobermorite: Ca 5 Si 6 O 16 (OH) 2 ·4H 2 O 19 Panunzite: (K, Na)AlSiO 4

• Specific heat water: 4.2 kJ kg -1 K -1 • Latent heat of evaporation: 2.3 kJ kg -1 • 1 kg K 2 O 8.6 kg material 6.5 kg rock • Latent heat: 77.2 kJ kg -1 H2O • Specific heat: 64.2 kJ kg -1 H2O • Grinding: 258.6 kJ • Total heat = 0.4 GJ ton K2O 20

PARTICLE SIZE DISTRIBUTION 21

ELEMENTAL RELEASE Release of Si and Ca 2+ from hydrothermal material (24 h, pH=5, agitation) K-feldspar hydrothermal material 22

MINERALOGICAL COMPOSITION 23

24

MINERALOGICAL COMPOSITION Electron microprobe 25

HYDROTHERMAL PROCESSING 26

Recommend

More recommend