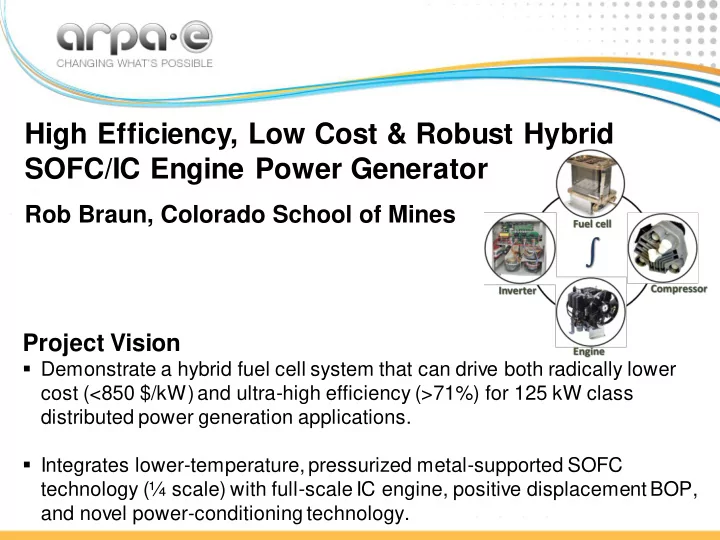

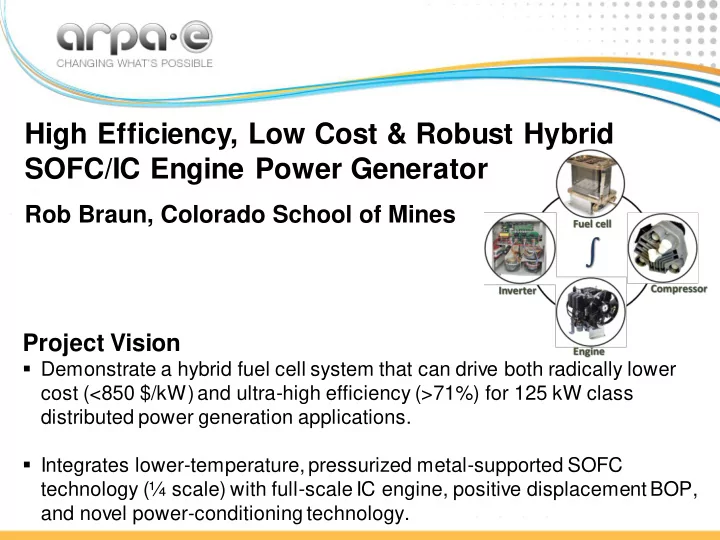

High Efficiency, Low Cost & Robust Hybrid SOFC/IC Engine Power Generator Rob Braun, Colorado School of Mines Project Vision Demonstrate a hybrid fuel cell system that can drive both radically lower cost (<850 $/kW) and ultra-high efficiency (>71%) for 125 kW class distributed power generation applications. Integrates lower-temperature, pressurized metal-supported SOFC technology (¼ scale) with full-scale IC engine, positive displacement BOP, and novel power-conditioning technology.

Fed. funding: $3.1M Project Overview Length 24 mo. Team member Location Role in project Mines Golden, CO Lead , Systems/Control, SOFC stack, TEA, T2M CSU Ft. Collins, CO Tail-gas engine, Integration test facility Kohler Power Kohler, WI Engine, Alternator, High efficiency/Low-cost Systems inverter, T2M, Commercialization partner Air Squared Broomfield, CO Scroll Compressor/Expander Context/History of project Mines: >20-yr experience on fuel cell systems and SOFC technology. : REBELS and REFUEL projects CSU : ARID project; long history in alt. fuels and stationary engines Kohler: Commercial/Industrial engine power systems from 20 kW to 40 MW Air Squared: World leader in scroll tech, >50 govt projects, GENSETS Key aspects: we started early, met continuously ahead of FOA, and leveraged existing relationships.

Innovation - Integrate robust, pressurized metal-supported SOFC with high h engine, inverter and rotating equipment Features: Low cell temp, thermal management reduce air preheater duty by >60% Pressurization increases power density, lowers both costs and BOP duty Gasified diesel engine converts residual fuel gas to drive auxiliaries (BOP) Simple after-treatment enables low engine emissions (NOx, CO) h = 35% 600°C 12-16 kW >350 mW/cm 2 >71% efficiency 125 kW h = 98% <850 $/kW Low cost

Technical Objectives & Organization Task 1: System Modeling for Integration and Control (CSM) Task 2: Pressurized Stack Module Development (CSM) Task 3: IC Engine & Alternator Development (CSU/Kohler) Task 4: Development of Compressor/Expander (Air-Squared) Task 5: Inverter Design and Fabrication (Kohler) Task 6: Fuel Cell Simulator & Integrated System Testing (CSU/CSM/Kohler) Task 7: Techno Economic Analysis and T2M (Tech to Market) - (CSM/Kohler)

Technology-to-Market Critical Loads Anticipated First Markets Critical loads Commercial Industrial CHP (eventually) Data Centers Approach to Market Industrial CHP • Analysis needed Commercial Buildings SOFC Hybrid Markets

Technology-to-Market Analysis Approach has 3 primary steps: SEGMENTATION TARGETING POSITIONING • Determination of key segment variables • Design positioning concepts • Attractiveness analysis of Spark Spread each segment Rate Structure • Selection of position Self Generation Incentives concept and Load Profile, Peak Load communication Corporate Sustainability Targets • Selection of target markets • Definition and segment of market • Leverage Kohler’s ability to scale • Clear and defined segment profiles Key Elements for Product Development & Success: Kohler’s ability to scale, systems integrator, and existing customer base to help define requirements Partnership with and access to pilot scale stacks from Ceres Power

Challenges and Potential Partnerships SYSTEM-LEVEL Control: o over dynamic operating range o through mode transitions Water/thermal management (esp. startup) Engine/FC interactions, Maintaining system pressure Heat exchangers COMPONENTS SOFC Stack Inverter Compressor/Expander Performance (>350 mW/cm 2 ) 98% efficiency Compressor efficiency/Scaling Pressurization (3-5 bar) Expander inlet temperature Durability (degradation, X-press D ’s, coking…) limit and maintaining efficiency Cost trajectory Engine Durability/service intervals for target life cycle (20,000-h) Combustion control with low-Btu/high moisture content fuel 35%-LHV engine efficiency target

The Team Rob Braun, Mechanical Engineering Neal Sullivan, Mechanical Engineering Tyrone Vincent, Electrical Engineering Rob Danforth, Director – Engineering Labs Isaac Frampton, Staff Engineer Todd Bandhauer, Mechanical Engineering Dan Olsen, Mechanical Engineering Brett Windom, Mechanical Engineering Bryce Shaffer

Recommend

More recommend