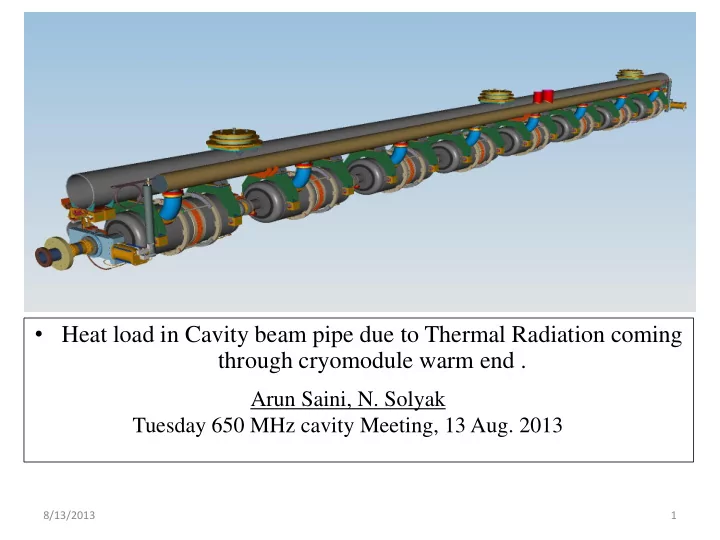

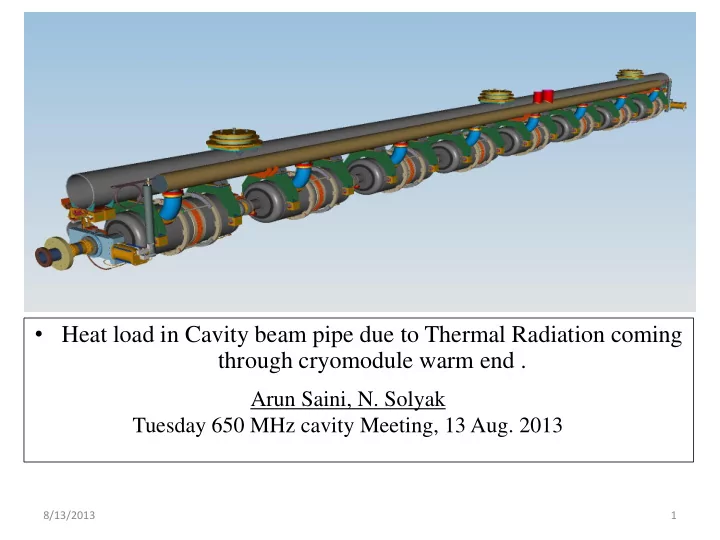

• Heat load in Cavity beam pipe due to Thermal Radiation coming through cryomodule warm end . Arun Saini, N. Solyak Tuesday 650 MHz cavity Meeting, 13 Aug. 2013 8/13/2013 1

Thermal Radiation • Radiation emitted by a surface: = 𝐵𝜗𝜏𝑈 4 Q – 𝜗 =1; for a black body. • Net radiation exchange between two surfaces: 4 4 .( T T ) 1 2 Q 12 ( 1 ) ( 1 ) 1 1 2 A . A . A F 1 1 2 2 1 12 For Black bodies 4 4 Q .( T T ). A F 12 1 2 1 12 8/13/2013 2

Case 1 : Maximum heat transfer from 300K to 2 K 300 K 2 K • Assumptions: – Both boundaries are next to each other. • No interception from 80 K and 5 K – Both are black bodies. • Net Radiation transfer {1} 4 4 Q .( T T ). A F 12 1 2 1 12 R 2 for 1 A F . R ; R 0 . 059 m 1 12 L Q 5 W 12 8/13/2013 3

Case 2 : Minimum heat transfer from 300K to 2 K • Assumptions: – 2K boundary is grey and opaque surface. • No transmission for opaque surface. 300 K 2K 1 1 2 0.05 {3} L • For L =0.2 m; Radiation reaching to cavity beam pipe ~ 0.16 W. • Conclusion : Radiation heat load lays in interval of [ 0.16 5] View Factor from bottom to curved surface {2} 8/13/2013 4

Case 3 : Simplified Realistic model 300 K 2 K 5 K 80 K 0.1 0.1 0.25 m 0.175 0.05 1 • ANSYS simulation is performed for simplified model. – Steady state surface to surface radiation boundary condition is applied. – Q Q Q ( 1 ) Q net emit inci inci – No Convection effect. – Emissivity of 80 K and 5 K Stainless steel pipe is varied. 8/13/2013 5

Power deposited in Cavity Beam Pipe (BP) S.Steel BP Cavity BP • Conclusion: • High emissivity of 80 K and 5K pipes can reduce energy deposition in P total = 0.2358 W Cavity BP. • Reducing the radius of P total = 0.1355 W Steel BP might also help. P total = 0.05 W 8/13/2013 6

How to increase emissivity Black Surface Rough Black Surface • Rough surface is better attenuator than smooth surface. – Sandblasting and chemical etching • High emissivity also leads to high conduction heating load which can be easily intercepted by 80 K and 5 K cold sheild. • SNS data suggests that 70 % of total static heat load comes from thermal radiation. 8/13/2013 7

Temperature Distribution in Cavity Beam Pipe For 1D steady state equation. 2 T q 2 z K q Rate of heat generated per unit volum e of beam pipe K = Thermal conductivity. T 2 K ( T 1 ). dT i T K ( i ) 1 avg T T 2 1 Q 0.16m T2 =2K 8/13/2013 0.m 8 T1 =5K

Thermal conductivity data :D. Reschke/DESY, Dec. 2003 Termal Conductivity vs. Temp 1000 Wärmeleitfähigkeit [W/mK] 100 10 RRR=760 RRR=525 RRR=400 RRR=270 RRR=120 RRR=40 1 1 10 Temperatur [K] ( ) 2 ( ) 3 ( ) 4 ( ) 5 L270T ( ) exp 4.57848 31.01ln T ( ) 54.77795ln T 46.41167ln T 17.89282ln T 2.56625ln T Fit: ( ) 2 ( ) 3 ) 4 ( ) 5 L400T ( ) exp 4.38 31.0ln T ( ) 54.69ln T 46.40ln T 17.917 ln T ( ( ) 2.5741ln T 8/13/2013 9

Thermal conductivity K average with no. of iteration Thermal conductivity along beam pipe 8/13/2013 10

Temperature Distribution in beam pipe for different emittances Input power is 2 W • 2W Temperature distribution for different emissivity, Power Input 2 W 10 e =1.0 e =0.75 9 e =0.5 e =0.25 8 e =0.1 T2 =2K e=0.05 T1 =5K no power deposit 7 Temperature (K) 6 5 4 3 2 1 0 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 z (m) 8/13/2013 11

Maximum Temperature in Cavity Beam Pipe Variation in Max. Temperature with Variation in Max. Temperature input thermal radiation with emissivity 8/13/2013 12

Calculation of additional RF losses in cavity beam pipe. • Rise of temperature in beam pipe results increase in BCS surface resistance. • Surface resistance is calculated for given temperature distribution in beam pipe. – Assumption T T T 2 c c Rs ( T ) Rs ( 2 K ) * * exp( . ) T T c T k . T T T • Rs = 10 n W @ 2 K. B c 2 . . f Rs T T c 1 2 . . . P Rs H ds d 2 . U Q P d • Surface magnetic fields in beam pipe is calculated using SLANS for 1 J stored energy. • For Max. Voltage gain of 17.5 MeV in 650 MHz cavity, stored energy is ~ 122.5 J. 8/13/2013 13

Surface resistance & RF power dissipation in beam pipe. Input power is 2 W • Surface Resistance along beam pipe RF Power dissipation in beam pipe for operating gradient Surface Resistance along beam pipe for different emissivity, Power Input 2 W 4 10 1 e =1.0 10 e =0.75 e =1.0 e =0.5 Power Dissipation in Beam Pipe (mW) e =0.25 e =0.1 3 e=0.05 10 0 10 Rs (n Ohm) 2 -1 10 10 Q 0 ~ 2.9E+13 -2 10 1 10 -3 10 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 0 10 z (m) 0 0.02 0.04 0.06 0.08 0.1 0.12 0.14 0.16 z (m) 8/13/2013 14

Heat load in Cavity beam pipe due to Thermal Radiation coming through Power coupler Power coupler for 650 MHz cavity Dimensions of cold part of power coupler 8/13/2013 15

Radiation Surfaces. Antenna @ 300 K Ceramic Window @ 300 K Antenna tip @ 300 K Cavity Beam pipe @ 2K • Emissivity of Ceramic Window =1. • Emissivity of Antenna tip and Antenna = 0.1 • Emissivity of Niobium pipe = 0.05 ANSYS simulation shows power deposition in cavity beam pipe is ~ 0.15 W 8/13/2013 16

Summary • Analysis is performed to analyze heat load in beam pipe due to cryomodule warm end and power coupler. – Estimation for simplified configuration shows no problem in beam pipe. • Next Steps – Improving the model and perform the more precise studies. 8/13/2013 17

References 1. http://webserver.dmt.upm.es/~isidoro/tc3/Radiation%20View%20factors.pdf 2. http://www.dtic.mil/dtic/tr/fulltext/u2/a284447.pdf 3. http://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=05643103 8/13/2013 18

Back-up slides 8/13/2013 19

8/13/2013 20

8/13/2013 21

8/13/2013 22

8/13/2013 23

Recommend

More recommend