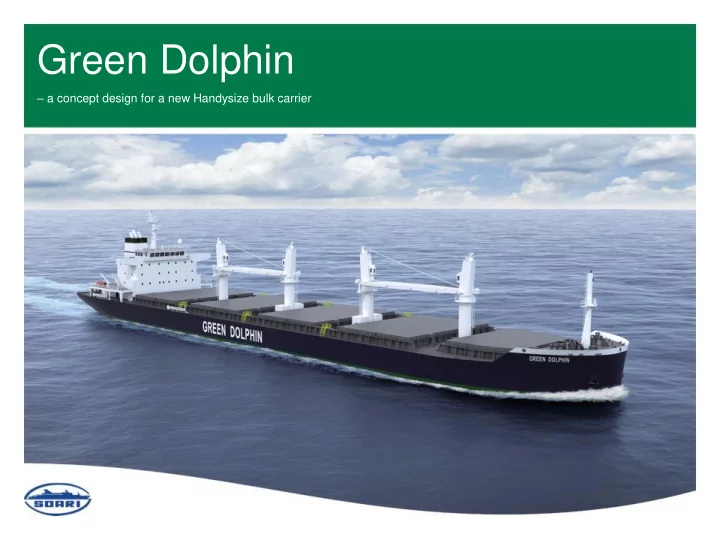

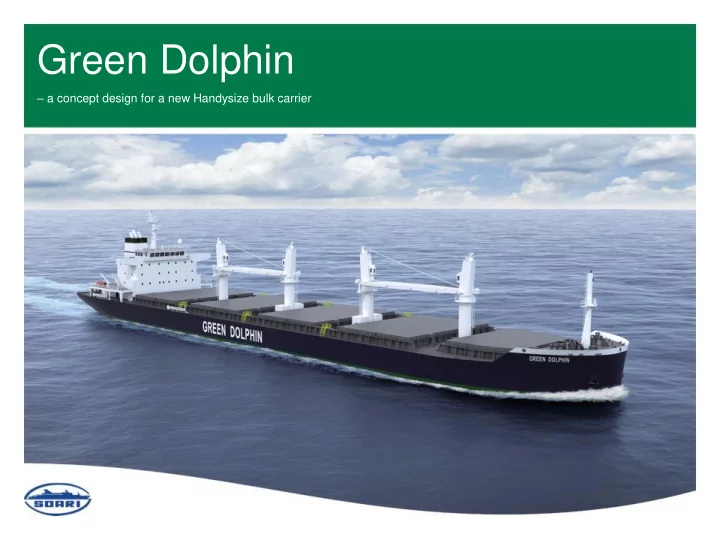

Green Dolphin – a concept design for a new Handysize bulk carrier

A joint development project • Project phases – Phase 1: SDARI, DNV and Wärtsilä have worked closely together – Phase 2: SDARI will independently prepare basic design – DNV will later carry out class approval in principle. • Challenging market situation – Low freight rates – High fuel prices – New environmental standards • The project concentrates on existing technologies currently available for commercial use 5 June 2012 By SDARI, DNV and Wärtsilä

Developed in cooperation with ship owners and shipyards • Objective – Meet ship owner and shipyard needs as well as environmental regulations • Input – Market and logistics study – Input also received from ship owners and shipyards • Focus areas – Robust and reliable – Fuel efficiency – Environment-friendly and – Operational flexibility prepared for future regulations Input from ship owners 5 June 2012 By SDARI, DNV and Wärtsilä

Concept overview Main particulars Length over all 180 m Draught, scantling 10.5 m Length between perpendiculars 177 m Draught, design 9.5 m Breadth 32 m Deadweight, scantling 38,800 mt Depth 15 m Deadweight, design 33,400 mt 50,500 m 3 Cubic capacity (grain) Service speed at design draught 14.0 kn • Double hull bulk carrier designed to IACS Common Structural Rules • Five flush cargo holds with high cubic and deadweight capacity • Wide hatches with foldable double-skin hatch covers FUEL AND ENERGY EFFICIENT OPERATIONAL FLEXIBILITY • Four electric deck cranes with variable frequency drive ROBUST AND RELIABLE • Designed to carry a wide range of cargoes ENVIRONMENT-FRIENDLY AND PREPARED FOR FUTURE REGULATIONS 5 June 2012 By SDARI, DNV and Wärtsilä

Fuel efficiency Hull optimisation and propulsion – a SDARI and DNV combined effort • Hull form optimisation by use of Computational Fluid Dynamics • Large propeller, low rpm • Wake equalising duct, rudder transition bulb and rudder fins • Main engine with economical performance over the whole operating range Low fuel consumption achieved at a range of service conditions • Daily main engine fuel consumption at 14 kn at 9.5 m draught: 17.7 t • Daily fuel consumption at 10 kn slow-steaming: 6.4 t • Energy Efficiency Design Index (EEDI) 25% below the IMO reference line for bulk carriers Wake distribution Wave pattern Propeller, rudder and propulsion-efficiency devices 5 June 2012 By SDARI, DNV and Wärtsilä

Operational flexibility Focus on cargo handling and maintenance friendliness • Suitable to carry a wide range of cargoes, including deck cargoes • High tank top load capacity for steel coil loading • Electric variable frequency drive deck cranes • Wide hatch openings • Double-skin flush cargo holds without hopper or top side tanks in cargo holds 2, 3 and 4 • Cargo hold recess for compressed air, power and wash water supply • Tanks for clean and dirty cargo hold wash water • Separated dirty and clean ballast water tanks Midship section, steel coil loading 5 June 2012 By SDARI, DNV and Wärtsilä

Robust and reliable Safety and structural integrity at the center of the design • Double hull construction • IACS Common Structural Rules for Bulk Carriers • Continuous hatch coamings • Heavy ballast condition achieved without using cargo hold • All fuel oil tanks located in the engine room • A60 fire insulation of engine room bulkhead • Cargo hold CO 2 fire fighting system • Safe access for crew and stevedores • Piracy protection with citadel Clearly marked ladders and handrails 5 June 2012 By SDARI, DNV and Wärtsilä

Environment-friendly Specific attention paid to performance and emission reduction • Wärtsilä 5 cylinders two-stroke low-speed RT-flex50, IMO Tier II compliant • Low fuel consumption level through the complete load range • Compliant with existing NO X or SO X regulations • Dual-fuel version available, utilizing low-pressure gas injection • Ballast water treatment system • Integrated bilge water treatment system • Water-lubricated stern tube bearings Illustration • Class notations CLEAN and RECYCLABLE Existing and new environmental regulations 5 June 2012 By SDARI, DNV and Wärtsilä

Prepared for future regulations Different versions to comply with upcoming local and global regulations • Base case design runs on heavy fuel oil Options exist to owners ’ preference • Scrubber system • Selective Catalyst Reduction (SCR) • Dual-fuel operation with LNG Illustration SCR and scrubber installation LNG tank installation 5 June 2012 By SDARI, DNV and Wärtsilä

• Fuel efficiency • Operational flexibility • Robust and reliable • Environment-friendly and prepared for future regulations

Recommend

More recommend