Global Warming H How Can Biofuels Help? C Bi f l H l ? Cli t - PowerPoint PPT Presentation

Global Warming H How Can Biofuels Help? C Bi f l H l ? Cli t Willif Clint Williford d Department of Chemical Engineering I t Introduction d ti Greenhouse emissions Reducing growth of GHG emissions Reducing growth of GHG

Global Warming H How Can Biofuels Help? C Bi f l H l ? Cli t Willif Clint Williford d Department of Chemical Engineering

I t Introduction d ti � Greenhouse emissions � Reducing growth of GHG emissions � Reducing growth of GHG emissions � Biofuels � Why and why now? � Wh and h no ? � What they are? � How they are made? � How they are made? � Potential for energy & GHG reduction � Issues � Issues 2

3 Introduction ti d I t

4 Introduction

5 Introduction

6 Introduction

7 Greenhouse Emissions Greenhouse Emissions Greenhouse Emissions Greenhouse Emissions

8 ssions ons i ouse Emiss i i Greenhouse Em h h Green

9 ssions ons i ouse Emiss i i Greenhouse Em h h Green

10 ssions ons i ouse Emiss i i Greenhouse Em h h Green

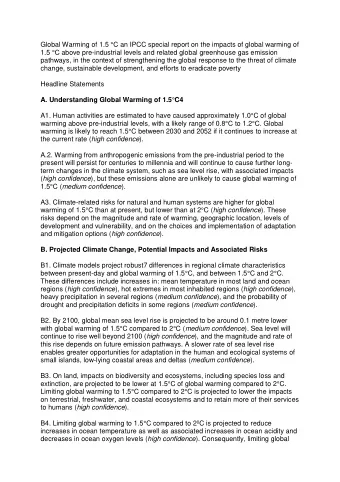

Greenhouse Emissions Greenhouse Emissions Preindustrial Current Increase since Radiative Gas Forcing(W/m 2 ) Level Level 1750 Carbon 280 ppm 280 387 387ppm 104 ppm 104 1.46 1 46 Dioxide Methane 700 ppb 1,745 ppb 1,045 ppb 0.48 Nitrous 270 ppb 314 ppb 44 ppb 0.15 Oxide CFC-12 0 533 ppt 533 ppt 0.17 11

Reducin Reducing Growth o Growth of GHG GHG Emissions Emissions � xx 12

R d Reduc ucing G i g Grow G G rowth th th of GHG E h f GHG f GHG E f GHG Emiss i ssions i ons � xx � 1 Wedge – Increase Bio EtOH X 50 13

Bio Biofue f f uels- l l s- Why Wh Wh Why & &Why Wh Wh Why Now? Now? � 2006 – Tipping Point for industrial biotech & cell EtOH � 2006 Tipping Point for industrial biotech & cell EtOH � Higher energy prices � C � Concern for energy security f it � Global warming – a mainstream issue � Technological advance - enzymatic hydrolysis � Political support – farmers, environmentalists, security interests, business leaders, politicians � Grain corn ethanol building an industry and a market g y 14

15

T T Typ Types o es of B f f Biofue i f uels l � Biodiesel � Grain corn ethanol � Cellulosic ethanol (Cell EtOH) � Others – Butanol, Renewable biodiesel 16

Biodiesel Biodiesel � Biodiesel is known chemically as a 'fatty acid methyl ester’ � “Transesterification” � Vege oil or fat reacted with an alcohol using a catalyst, usually a base (OH - ) ll b (OH ) � Settling and washing steps � Glycerol is main byproduct http://www.utahbiodieselsupply.com/biodieselbasics.php 17

Biodi i d i di diese esel l http://pathtofreedom.com/pathproject/offthegrid/biodiesel.shtml 18

T T Typ Types o es of B f f Biofue i f uels l http://pathtofreedom.com/pathproject/offthegrid/biodiesel.shtml 19

20 Biodiesel Biodiesel Biodiesel Biodiesel

Biodi i d i di diese esel l Production and demand surging;$1/gal blending incentive 21

Gra Grain Corn B i i n Corn Bioet i i oethano h anol l � Ethanol (CH3CH2OH; also known as ethyl alcohol, ( ; y , grain alcohol, and EtOH) is a clear, colorless liquid. http://www.eere.energy.gov/afdc/fuels/ethanol_what_is.html And http://arreffett.iweb.bsu.edu/ethanol.htm 22

Gra Grain Corn B i i n Corn Bioet i i oethano h anol l � Ethanol produced from corn and sugar crops by dry � Ethanol produced from corn and sugar crops by dry milling � Main products: EtOH,CO 2 , high protein animal feed wet p g p 2 distillers grains with solubles or WDGS � Corn is ground into coarse flour � Water and enzymes are added and the mixture "cooked“ � Yeast is added, and the mixture fermented. � The “mash” is distilled to recover the EtOH Th “ h” i di till d t th EtOH 23

Grain Corn Bioethanol Grain Corn Bioethanol Grain Corn Bioethanol Grain Corn Bioethanol http://www.ethanolrfa.org/objects/documents/337/mgpcd3-1.wmv 24

25 Grain Corn Bioethanol Grain Corn Bioethanol Grain Corn Bioethanol Grain Corn Bioethanol

26 anol l c Ethano h osic Et i llulos ll l ll Cell Ce

Cell Ce ll llulos ll l osic Et i c Ethano h anol l � Cellulose - main component in plant cell walls � Cellulose main component in plant cell walls � Most common organic compound on earth � A polymer of glucose � Enzymes convert to glucose � Yeats ferment to EtOH � B t � But, resists conversion i t i � Requires pretreatment- acids, high Temp & Pres 27 http://www.lsbu.ac.uk/water/hycel.html

Cell Ce ll ll l llulos osic Et i c Ethano h anol l � Potential to convert 1 billion tons biomass per year to � Potential to convert 1 billion tons biomass per year to replace 30% of U.S. petroleum use 28

Cellulosic Ethanol Cellulosic Ethanol Cellulosic Ethanol Cellulosic Ethanol � Iogen making CellEtOH in Canada � Other R& D & demo plants in works p � Needs for better enzymes, pretreatment, plant yields, etc. http://www.seco.cpa.state.tx.us/re_ethanol.htm 29

CO2 Emissions � xx 30

U o U of M Pro f f M Project j j ect Microbial conditioning with alternate pretreatment – improved ethanol yield, economics, and useable lignin adhesives improved ethanol yield economics and useable lignin adhesives Conditioning Enzyme Opportunities Production Harvest Harvest Simultaneous Lignin as a Size Alternate Saccharification higher value Reduction Pretreatment & Fermentation product p Ethanol Recovery 31

Switch Grass Switch Grass Sorghum Sudan Grass Sorghum Sudan Grass Medicinal Plant Garden, University of Mississippi 32

Introduction Introduction � Greenhouse emissions � Bi f � Biofuels – what they are; how they are l h t th h th made; their potential for fuel; and impact on GGE GGE � Issues 33

Fossil Ener Fossil Energy gy Re Replacement lacement Ratio Ratio Energy Delivered to Customer Fossil Energy Ratio (FER) = Fossil Energy Used 6 6 5.3 5 4 3 2 1.4 0.8 1 0.4 0 Cellulosic Corn Ethanol Gasoline Electricity Ethanol Source: J Sheehan & M Wang (2003) Source: J. Sheehan & M. Wang (2003) Biorefinery 34

Fossil Ener Fossil Energy gy Re Replacement lacement Ratio Ratio � http://www.rangefuels.com/interactive-map.html 35

Others Others Emerging Fuels Biobutanol Biogas Biomass to Liquids Bi t Li id Coal to Liquids Fischer-Tropsch Diesel Gas to Liquids Hydrogenation-Derived Renewable Diesel P-Series P Series 36 http://www.eere.energy.gov/afdc/fuels/emerging.html

Issues and Implications Issues and Implications– How How Green are Biofuels? � Net energy & fossil fuel use � Net GHG emissions reduction � Deforestation for palm oil plantations � Nitrous oxide emissions from fertilizer � Food prices � Food and grain exports � U.S. and world food prices (especially developing) d ld f d i ( i ll d l i ) � Opportunity Costs – Iowa study – grain EtOH 18 B gal; Cell EtOH 4 5 B gal (w/$1 55 incentive) Cell EtOH 4.5 B gal (w/$1.55 incentive) 37

Recommend

More recommend

Explore More Topics

Stay informed with curated content and fresh updates.