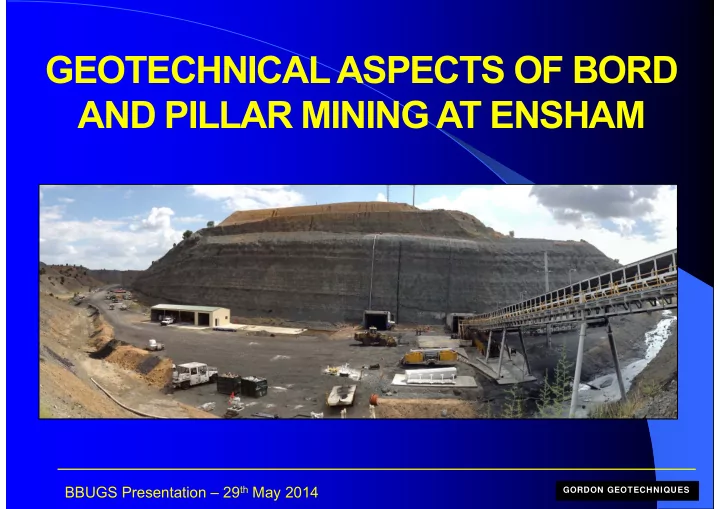

GEOTECHNICAL ASPECTS OF BORD AND PILLAR MINING AT ENSHAM BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

OUTLINE OF PRESENTATION • MINE LAYOUT • ENGINEERING GEOLOGY • MINING METHOD • MINING HORIZON • PRODUCTION RESULTS • GROUND SUPPORT • FAULTING • ROOF SPLIT • STRESS CONDITIONS • GROUNDWATER • PILLAR DESIGN BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

MINE LAYOUT • >2.5 Mt mined so far BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

STRATIGRAPHY • Extract the coalesced Aries-Castor Seam (A2C) in the Rangals • Seams split to north and south. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

SEAM THICKNESS AND SPLITS A211 PLY ROOF SPLIT CASTOR SPLIT BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

DEPTH OF COVER BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

MINING METHOD 7 HEADINGS 9 HEADINGS BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

DEVELOPMENT CONDITIONS Roadways 6.5 m wide and 3.5 m high. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

BOTTOMS EXTRACTION Typically 1-1.4 m of bottoms. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

POCKETING • For a 5 m extraction height, 1500-2000 tonnes in each pocket BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

ROOF LITHOLOGY AND STRENGTH • Immediate 2 m of stone roof - 20-40 MPa. • 2-6 m of stone roof – 30-40 MPa. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

MINING HORIZON • Initially mined to stone roof but slabbed in places. • Now mine to penny band 0.9-1.1 m from roof leaving the higher ash coal in the roof BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

MINING CONDITIONS BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

PRODUCTION HIGHLIGHTS (FOR TWO UNITS) • Best Shift - 4,777 tonnes • Best Day - 7,578 tonnes • Best Week - 40,140 tonnes • Best Month - 145,649 tonnes • 140,000 tonnes/month equates to 80 km/year of a typical 5 m x 3 m gateroad drivage BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

90 DAY AVERAGE PRODUCTION 5000 4500 90 Day Average 4000 800kt Per Unit Rate 3500 Tonnes per Day Mined 3000 2500 2000 1500 1000 500 0 BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

GROUND SUPPORT • 4 x 1.5 m roof bolts every 1.5 m in a 6.5 m wide roadway. • 1 x 1.5 m rib bolt mid pillar and 2 x 1.5 m rib bolts on corners. • In coal roof, only mesh services roadway and when triggered by the TARP. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

ROOF BOLTING ISSUES IN FAULTED AND ROOF SPLIT AREAS • Centre cracking in coal roof beam. • Gloving on roof bolts. • Fracturing at top of bolted horizon. • Poor encapsulation. 1200 Average SW MAINS = 220 mm Average NW MAINS = 575 mm LENGTH OF NON ‐ ENCAPSULATION (mm) 1000 800 600 400 SW Mains 49 ‐ 50CT 200 NW Mains 1 ‐ 4CT 0 0 2 4 6 8 10 12 14 16 18 20 22 SAMPLE NUMBER BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

POTENTIAL DEFICIENCIES IN BOLTING SYSTEMS (ACARP Project C21023 – Mine Advice) Gloving and unmixed resin at top of the bolt Lower ratio Higher ratio Different mastic/catalyst ratios Resin back pressure BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

NEW SYSTEM • 500 mm, 2:1 fast set resins in 28 mm holes using 200 mm square plates. • With 1.5 m bolts still get 70-75% encapsulation. BENEFITS • Guaranteed tensioning of the roof and rib bolts. • Reduction/elimination of gloving and unmixing of the resin at the back of the hole. • Reduction in roof bolt length for the same effective support. • Reduces the variety of plates and bolts used in a panel - 200 mm plate replacing star plates and dragonfly plates. • Reduced manual handling. • Reduced pressure at back of hole due to shorter resin. • Also looking at bolts with “neutral” deformations so that no resin pumping action is generated further reducing back pressure. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

HISTORY OF GROUND SUPPORT DATE SUPPORT INSTALLED October 2011 1.8 m roof and rib bolts with 1000 mm, 4:1 water based resins and roof mesh. May 2012 Dropped off mesh in stone roof roadways in NW1 Panel. January 2013 Leave coal roof in SW Mains and SE2 Panels. March 2013 Dropped off mesh in some coal roof roadways in SW Mains August 2013 In seam split area (interburden >0.8m), initially additional 2 x 4 m cables every intersection reduced to 4 x 2.4 m bolts. November 2013 Reduce rib bolt pattern from 2 bolts/1.5 m to 1 bolt/1.5 m in the mid pillar region. December 2013 Reduce rib bolt length to 1.2 m. February 2014 Introduced 500 mm water based 2:1 fast set resins and increased to 28 mm diameter bolt hole. Late March 2014 1.5 m roof and rib bolts. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

FAULTING BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

FAULT CONDITIONS BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

DETERIORATION OF COAL ROOF NEAR FAULTS BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

ROOF SPLIT 1.5m BOLTS 1.8m BOLTS BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

ROOF SPLIT • Need to anchor securely into the stone roof above the A211 coal ply. • Stone between split and main seam is weak. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

ROOF MONITORING IN SEAM SPLIT AREA 20 B2 SE3 EXTENSION ‐ 18 LARGE INTERSECTION NEAR A FAULT 16 TOTAL MOVEMENT (mm) 14 12 10 8 6 4 2 0 0 0.2 0.4 0.6 0.8 1 1.2 1.4 1.6 1.8 2 THICKNESS OF SEAM SPLIT INTERBURDEN (m) BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

ROOF MONITORING BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

RIB CONDITIONS – ORIENTATION • 103 Panel reoriented to maximise recovery between faults BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

HORIZONTAL STRESS • NNE trending orientation • Major Horizontal:Vertical – 1.3-2 BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

GROUNDWATER • One of the major factors affecting productivity. • Stubs on down dip side of panel. • Easier to mine down dip as can manage water at the face. • Mining uphill water sits outbye of face and harder to manage. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

PILLAR DESIGN - FACTOR OF SAFETY • FOS >1.6 below the flood plain. • FOS>2.11 below the Nogoa and Anabranch. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

PILLAR DESIGN – WIDTH TO HEIGHT BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

PILLAR SIZES Have tried different sizes including: • 14.5 m x 14.5 m (solid) • 14.5 m x 17.5 m (solid) • 16 m x 17.5 m (solid) • 17.5 m x 17.5 m (solid) • 17.5 m x 21.5 m (solid) Preferred size that suits the place change method with 14 m plunges is 16 m x 21.5 m (solid) – 45.4% extraction ratio. BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

PILLAR DESIGN AND FAULTS BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

PILLAR DESIGN AND SOFT FLOOR • Very soft floor layers (<1 MPa) can lead to panel collapse. • No signs of floor heave at Ensham. • Immediate floor strength 10-30 MPa COAL FLOOR BBUGS Presentation – 29 th May 2014 GORDON GEOTECHNIQUES

Recommend

More recommend