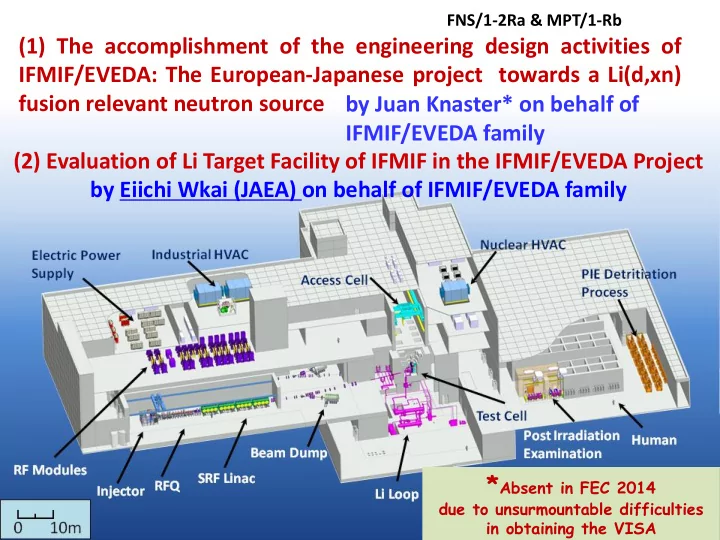

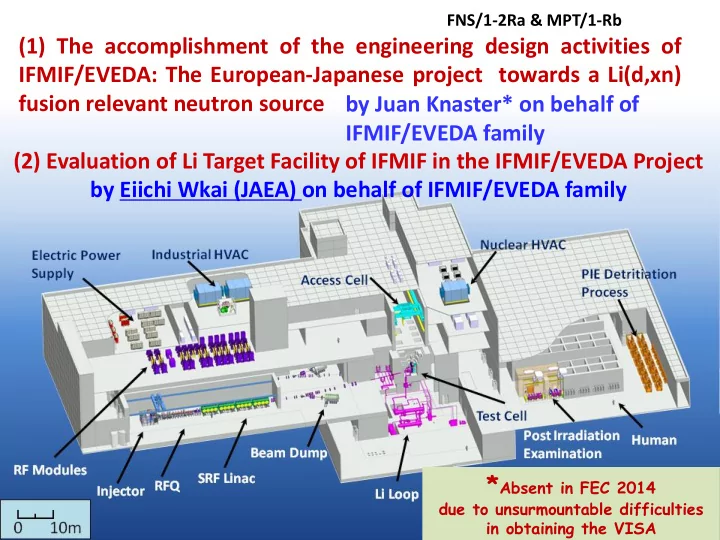

FNS/1-2Ra & MPT/1-Rb (1) The accomplishment of the engineering design activities of IFMIF/EVEDA: The European-Japanese project towards a Li(d,xn) fusion relevant neutron source by Juan Knaster* on behalf of IFMIF/EVEDA family (2) Evaluation of Li Target Facility of IFMIF in the IFMIF/EVEDA Project by Eiichi Wkai (JAEA) on behalf of IFMIF/EVEDA family * Absent in FEC 2014 due to unsurmountable difficulties 1 in obtaining the VISA

IFMIF/EVEDA IFMIF: International Fusion Materials Irradiation Facility EVEDA: Engineering Validation & Engineering Design Activities Article 1.1 of Annex A of the BA Agreement mandates IFMIF/EVEDA …to produce an integrated engineering design of IFMIF and the data necessary for future decisions on the construction, operation, exploitation and decommissioning of IFMIF, and to validate continuous and stable operation of each IFMIF subsystem ( Signed in February 2007, Entered into force on June 2007) J. Knaster FEC 2014 – Saint Petersburg 2

IFMIF through all technical steps IFMIF evaluation has successfully passed through all needed key steps as below: Conceptual Design Activity (CDA) phase in 1996 As a joint effort of the EU, Japan, RF and US Conceptual Design Evaluation (CDE) report in 1998 Towards a design simplification and cost reduction The Conceptual Design Report (CDR) in 2004 Co-written by a committee of EU, Japan, RF, US The final Phase of EVEDA within BA activities from 2007 As an efficient risk mitigation exercise to face the construction on cost and schedule timely with the world needs for a fusion relevant neutron source J. Knaster FEC 2014 – Saint Petersburg 3

IFMIF Concept 125 mA CW deuterons at 40 MeV collide on a liquid Li screen flowing at 15 m/s A flux of neutrons of ~10 18 m -2 s -1 is generated in the forward direction with a broad peak at 14 MeV and irradiate three regions >20 dpa/y in 0.5 liters >1 dpa/y in 6 liters <1 dpa/y in 8 liters Materials will be tested in the PIE Availability of facility >70% J. Knaster FEC 2014 – Saint Petersburg 4

A Fruitful International Collaboration IFMIF/EVEDA A fruitful Japanese- European International collaboration under the BA Agreement with 7 countries involved with the respective main research labs in Europe and main universities in Japan J. Knaster FEC 2014 – Saint Petersburg 5

Two Work Packages EVEDA Phase presents two parallel work packages EDA Phase Engineering Design Activities EVA Phase Engineering Validation Activities J. Knaster FEC 2014 – Saint Petersburg 6

Design of IFMIF The Design of IFMIF is broken down to 5 facilities Accelerator Facility Objective of Lithium Target Facility Validation activities Test Facility Post-irradiation and Examination Facility Conventional Facilities Post Irradiation Post Irradiation Examination Facility Examination Facility Accelerator Facility Accelerator Facility Test Facility Test Facility Hot Cell Hot Cell PIEF Ancillary PIEF Ancillary Laboratory Laboratory Access Cell Access Cell systems systems Tritium Hot Tritium Hot Lithium Target Lithium Target Cell Lab. Cell Lab. RH systems RH systems RH systems LEBT LEBT LEBT LEBT Thickness 25 ± 1 mm Thickness 25 ± 1 mm Ion Ion Ion Ion MEBT MEBT MEBT MEBT Flow speed 15 m/s Flow speed 15 m/s Be Hot Cell Be Hot Cell source source source source Lab. Lab. RFQ RFQ RFQ RFQ HEBT HEBT HEBT HEBT Superconducting Superconducting Superconducting Superconducting 1 1 1 1 0 0 0 0 0 0 0 0 k k k k e e e e Test Test Test Test Liquid Metal Liquid Metal V V V V Target Target Maintenance Maintenance 5 5 5 5 cavities cavities cavities cavities M M M M e e e e Modules Modules Lab. Lab. V V V V system system Facility Facility 9 9 9 9 systems systems 1 1 1 1 4 4 4 4 . . . . 5 5 5 5 Test Test Ancillary Ancillary Handling Handling 2 2 2 2 6 6 6 6 AF Ancillary systems AF Ancillary systems 4 4 4 4 0 0 0 0 Macrography Macrography M M M M e e e e V V V V Modules Modules systems systems cells cells Superconducting Superconducting Superconducting Superconducting Lab. Lab. cavities cavities cavities cavities RFQ RFQ RFQ RFQ Microscopy Microscopy 100 keV 5 MeV 9 14.5 26 40 MeV 100 keV 5 MeV 9 14.5 26 40 MeV 100 keV 5 MeV 9 14.5 26 40 MeV 100 keV 5 MeV 9 14.5 26 40 MeV Test Cell Test Cell Ion Ion Ion Ion Lab. Lab. source source source source LF Maintenance LF Maintenance E E B B T T M M systems systems LEBT LEBT Main Li Main Li Secondary Secondary Quench Quench Tertiary oil Tertiary oil Impurity control Impurity control tank tank loop loop oil loop oil loop loop loop system system Cooling water Cooling water Primary Primary Secondary Secondary Tertiary Tertiary from /to from /to Buildings Buildings Buildings Heat Heat EMP EMP Heat Heat Heat Heat Conventional Conventional Exchanger Exchanger Site General Infrastructures Site General Infrastructures Site General Infrastructures Exchanger Exchanger Exchanger Exchanger Facilities Facilities EMP EMP EMFM EMFM Plant Services Plant Services Plant Services Pump Pump Pump Pump Li Dump Li Dump Conventional Conventional Dump Dump Dump Dump tank tank Y Trap Y Trap Ti Trap Ti Trap Cold trap Cold trap Heat removal system Heat removal system Tank Tank Tank Tank Facility Facility LF Ancillary systems LF Ancillary systems J. Knaster FEC 2014 – Saint Petersburg Lithium Target Lithium Target 7 Facility Facility

EVA Phase Advancing Successfully J. Knaster et al., IFMIF: overview of the validation activities, Nuclear Fusion 53 (2013) 116001 (18 pp) J. Knaster FEC 2014 – Saint Petersburg 8

EDA Phase Accomplished on Schedule Complete WBS, detailed 3D models of plant, RAMI of individual facilities, remote handling studies, DDDs of all sub-systems (x35), licensing scenarios, safety reports, cost and schedule… J. Knaster FEC 2014 – Saint Petersburg 9

Report available upon request at ifmif-eveda@ifmif.org J. Knaster FEC 2014 – Saint Petersburg 10

Main Design Improvements from CDR (CDR: Comprehensive Design Report) Alvarez-type Drift Tube Linac replaced by a Superconducting RF Linac Reduction in beam losses and operation costs Configuration of the Test Cell changed irradiation modules have no more a shielding function Improved irradiation flexibility and the reliability of the remote handling equipment Quench Tank of the Lithium loop re-located outside the Test Cell Reduction of tritium production rate and simplification of maintenance processes Maintenance strategy modified Allowing a shorter yearly stop of the irradiation operations and a better management of the irradiated samples. Mario Pérez and the IFMIF/EVEDA Integrated Project Team The Engineering Design Evolution of IFMIF: from CDR to EDA Phase J. Knaster FEC 2014 – Saint Petersburg SOFT 2014 11

Risk Analysis J. Knaster FEC 2014 – Saint Petersburg 12

Possible inquiries please juan.knaster@ifmif.org or at +81 (0) 175 71 66 35 www.ifmif.org Wikipedia J. Knaster et al. , IFMIF, a fusion relevant neutron source for material irradiation current status , J. Knaster FEC 2014 – Saint Petersburg Journal of Nuclear Materials 453 (2014) 115 – 119 13

Part II: EVEDA Li Test Loop Evaluation of Li Target constructed in JAEA-Oarai Facility of IFMIF in the IFMIF/EVEDA Project by Eiichi Wkai (JAEA) on behalf of IFMIF/EVEDA family J. Knaster FEC 2014 – Saint Petersburg 14

IFMIF Liquid Lithium Target Concept Liquid Li Condition: • Temp.: 250 o C, • Velocity: 15 m/s • Vacuum: 10 -2 -10 -3 Pa D + -Li stripping reaction generates high - intense neutrons to simulate fusion irradiation conditions. - High-speed liquid Li flow along concave back plate is selected as IFMIF target to handle a high heat load of 10MW D + beams. 15

Main Missions of EVEDA Li Test Loop (ELTL) Major Requirements for Li Target in IFMIF : 1 GW/m 2 • Averaged heat flux • Jet velocity : 15 m/s (range 10-20 m/s) • Jet thickness/Width : 0.025 m/0.26 m • Surface wave amplitude : < +/- 1 mm • Initial (inlet) Li temperature : 250 o C : 10 -3 - 10 -2 Pa near Li free surface • Vacuum pressure Main Missions of EVEDA Li Test Loop (ELTL) • Validation of stable long-time operation of a high-speed free-surface liquid Li simulating IFMIF target. • Validations of diagnostics on the Li flow and impurity control systems for a Li loop. 16

Recommend

More recommend