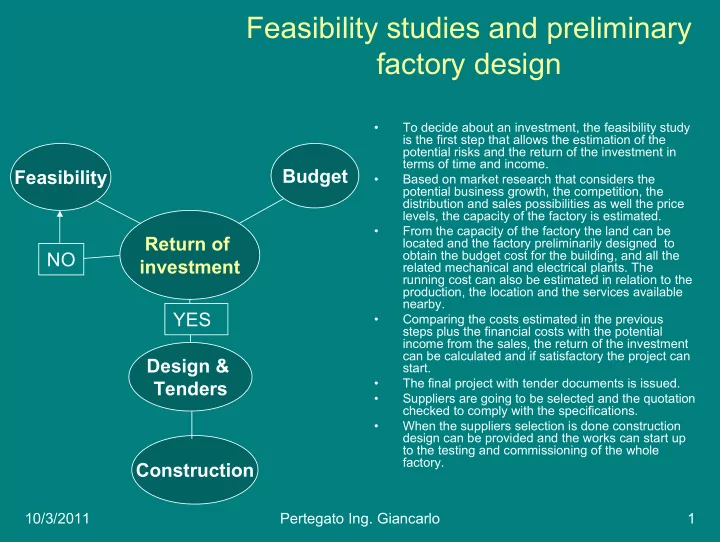

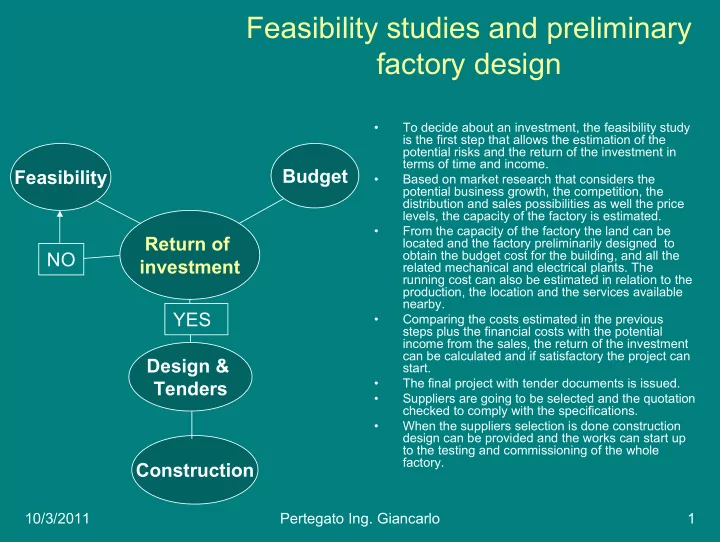

Feasibility studies and preliminary factory design • To decide about an investment, the feasibility study is the first step that allows the estimation of the potential risks and the return of the investment in terms of time and income. Budget Feasibility • Based on market research that considers the potential business growth, the competition, the distribution and sales possibilities as well the price levels, the capacity of the factory is estimated. • From the capacity of the factory the land can be Return of located and the factory preliminarily designed to obtain the budget cost for the building, and all the NO investment related mechanical and electrical plants. The running cost can also be estimated in relation to the production, the location and the services available nearby. YES • Comparing the costs estimated in the previous steps plus the financial costs with the potential income from the sales, the return of the investment can be calculated and if satisfactory the project can Design & start. • The final project with tender documents is issued. Tenders • Suppliers are going to be selected and the quotation checked to comply with the specifications. • When the suppliers selection is done construction design can be provided and the works can start up to the testing and commissioning of the whole factory. Construction 10/3/2011 Pertegato Ing. Giancarlo 1

Summarizing: • The advising services are provided step by step with the benefit that a wrong investment Input can be recognized from the beginning minimizing the wasted costs. • The cost for the go ahead on Feasibility study any project is the best investment because a project on wrong assumptions or data Preliminary project could be catastrophic and lay-out • Generally speaking the engineering and advising costs can vary between 1.5 and 7.5% Investment approval and final project of the total investment inversely with tender documents issuing to the amount (the higher the investment the lower the %) Contract with suppliers, construction design and project start up 10/3/2011 Pertegato Ing. Giancarlo 2

Three working steps Checking Checking Data Data T T a a Final Data Final Data r r g g e e t t Needs Needs Feasibility Feasibility Tendering Tendering Preliminary Checking Preliminary Final Checking Final Construction Construction t t c c e e j j o Interconnections o Interconnections r r P P Impact Impact Tenders Tenders 10/3/2011 Pertegato Ing. Giancarlo 3

Advantages • The design in several steps allows to modify the project according to the data acquisition and strategies with minimal impact when changes occur. • Any change in the design phase has a costs incomparably lower than in construction phase. • Invest in engineering means to minimize changes and modification during construction reducing the wasted costs generated by such changes Some projects are shown in the next slides 10/3/2011 Pertegato Ing. Giancarlo 4

Lanitis Bros. Ltd. TANKER 1 TANKER 2 TANKER 3 TANKER 4 10/3/2011 Pertegato Ing. Giancarlo 5

Christis Dairies Ltd. Limassol Cyprus Raw Material Store for: MAIN ELECTRIC BOARD 1. Straws for TBA 3 and TBA - 19 POWER GENERATOR Prisma 2. Carton Boxes for TBA 3 250/1000 & TBA 19 Prisma (for all different kinds) U.H.T. 3. Schrink for TBA 19 line & TBA 3 4. Glue for the carton Boxes and Straws line -25°C Store 5. Paper reels for the 3 machines, strip U.H.T. FILLING 28-FUTURE PACKED and aluminum strips for the pull tab 6. Chemical liquids for the macines CHEESE DRIVE IN COLD (Peroxide, external Cleaning, Acid, 29-DISPATCHING LFT) 7. Trolley for lifting and turning the HV TRANSFORMERS STORE 4° GRAVITY COLD STORE reels 4° 8. Raw materials needed for Mac Donalds 9. Ready product storage -45°C Freezer h=6.0m h=6.0m 21-FRESH MILK GRAVITY COLD STORE 4° CRATES STORE PACKAGING STORE DISPTACHING 15° 26-24TRADING AND h=6.0m h=6.0m h=6.0m UNPACK ROOM h=4.9m DISPATCHING COLD 15° YOGURT STORES 1ST FLOOR MILK FILLING/PAKING RIPENING (FUTURE PROVISION) 22-COLD STORE FOR 22° h=3.7m MILK PASTEURIZATION C.I.P. READY PALLETIZED GOODS FOR LOCAL MARKET 4° YOGURT BLAST CRATES WASHING RE-PACKING ROOM 15° h=3.7m COOLER -1° 30-BUFFER COLD STORE 4° (CLEAN ROOM) h=3.5m (lowered for ROW MATERIAL STORE technical space) SLICING DISPATCHING STORE TRADING AND 23-DRIVE IN COLD 24-DRIVE IN YOGURT STORE 4° COLD STORE 4° DISPATCHING COLD STORES GROUND FLOOR h=6.0m (FUTURE PROVISION) MILK MIXING ROOM 25-FUTURE FRESH MILK 9-PACKING ROOM GRAVITY COLD STORE Operator side V acu um port i ons (3 p acked x 3) h=6.0m h=6.0m 4° RECEIVING/DISPATCHING D ri v en bel t conve yor t U ni T urni ng met al st i ng bel t det ec t E x i or mount e co nveyor d w i h t C onverger Qu eui ng conveyor p ri Wei gh - c e machi ne l abe l i ng rej ect ar D ri ven con veyor m Out l e t f h i t w o r di ve r p r o duct s ed t LIFT LIFT OFFICES AND S t an dard out l et FACILITIES con veyor i vac Mul t t exi D i vert i n g poi nt i o (opt n) 17-FETTA MATURING 18° 18-FETTA STORAGE 4° l al S eparat i ng w 10-PACKING IN BOXES h=6.0m 16-FETTA PRODUCTION 19-HALLOUMI STORAGE 22° 4° 8-ACCESS FROM 7-COLD STORE BASEMENT h=4.9m 14-KEFALOTIRY 11-KEFALOTIRY 12-KEFALOTIRY 13-KEFALOTIRY MATURING 18° 15-KEFALOTIRY h=3.7m BRINING 10° PRODUCTION PRESSING 10° STORAGE 4° WORKSHOP 20-DRIVE IN EXPORT h=4.5m CHEESE STORE -18° h=6.0m BLAST COOLER LIFT 6-BRINING 4-FOLDING & SALTING CHEESE PRODUCTION 3-ANARI PRODUCTION BUFFER TANKS WASHING/STORAGE 2-MOULD 5b COW 100T TANKER 1 ANARI LABORATORY cold DRY STORE (UHT) - store 3-HALLOUMI COOKING PROCESSED CHEESE DRIVE IN COW 100T TANKER 2 MILK RECEPTION SHIP 40T TANKER 3 1-HALLOUMI PRODUCTION GOAT 40T TANKER 4 h=4.9m SEWAGE TANKER DRESSING ROOMS AND TOILETS RE-ADJUSTMENT SUGGESTED TO AVOID CROSS CONTAMINATION LIFT CANTEEN STORE CANTEEN STORE RAW MATERIAL COLD RAW MATERIAL COLD RAW MATERIAL COLD STORE STORE STORE DRESSING ROOMS AND TOILETS RAW MATERIAL BUFFER CANTEEN STORE 10/3/2011 Pertegato Ing. Giancarlo 6

Kasih Food Production Co. 10/3/2011 Pertegato Ing. Giancarlo 7

Recommend

More recommend